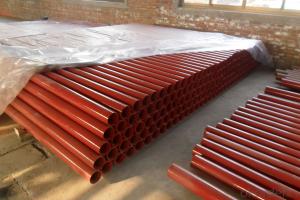

Ductile Iron Pipe With Competitive Price ISO2531/EN545

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Place of Origin: China (Mainland)

Model Number: T type / K type / Flange type

Length: 6M/5.7M/Negotiable

Standard: ISO2531/EN545 for portable water, EN598 for sewer lines

Application: Potable/Sewage Water

Diameter: DN80~DN1600

Shape: Round

Hardness: 230

Pipe Wall Thickness: STANDARD

Pull Strength: 420 Yield (≥ MPa): 300

Material: Cast Iron

Type: Ductile Iron Pipes

Outer Diameter: 80-1600

Thickness: standard

Usage: water pipe

1. hydraulic hose crimping machine in Electrical equipment&supplies

Specifications

High pressure hose to the winding wire matrix, skin coated refractory coating layer steel braided flame retardant layer

APPLICATIONS:It is mainly used in high temperature surroundings and in conditions having heat source or heat radiation source,such as oil field well-control,metal smelt,and chemical industry.

Inner Diameter of Hose mm | Inside Diameter | Reinforcement Diameter (mm) | Outside Diameter (mm) | Work Pressure (MPa) | Proof Pressure (MPa) | Minimum Explosive Pressure (MPa) | Minimum Bending Radius mm | Refractory °C | |||

Mpa | Psi | MPa | Psi | Mpa | Psi | ||||||

φ13(1/2") | 13±0.5 | 22.2±0.8 | 44±1.06 | 43 | 6230 | 64.5 | 9435 | 86 | 12460 | 230 | 750 |

φ16(5/8") | 16±0.5 | 26±0.8 | 47±1.5 | 38 | 5506 | 57 | 8259 | 76 | 11012 | 260 | 750 |

φ19(3/4") | 19±0.5 | 30±0.8 | 52±1.5 | 34.5 | 4999 | 51.75 | 7498 | 69 | 9998 | 300 | 750 |

φ25(1") | 25±0.8 | 36±0.8 | 59±1.5 | 27.5 | 3984 | 41.25 | 5976 | 55 | 7968 | 360 | 750 |

φ32(5/4") | 32±0.8 | 44±0.8 | 69±2.0 | 20.5 | 2970 | 30.75 | 4455 | 41 | 5940 | 470 | 750 |

φ38(3/2") | 38±1.0 | 76±2.0 | 87.2±5.1 | 17 | 2463 | 25.5 | 3694 | 34 | 4926 | 570 | 750 |

φ51(2") | 51±1.0 | 91±2.0 | 100.7±5.1 | 17 | 2463 | 25.5 | 3695 | 34 | 4926 | 740 | 750 |

2. Antiflaming,fire-resistance rubber hose assembly

Specifications

High pressure hose to the winding wire matrix, skin coated refractory coating layer steel braided flame retardant layer and laye

APPLICATIONS:It is mainly used in high temperature surroundings and in conditions having heat source or heat radiation source,such as oil field well-control,metal smelts,and chemical industry

Inner Diameter of Hose mm | Inside Diameter | Reinforcement Diameter (mm) | Outside Diameter (mm) | Work Pressure (MPa) | Proof Pressure (MPa) | Minimum Explosive Pressure (MPa) | Minimum Bending Radius mm | Refractory °C | |||

Mpa | Psi | MPa | Psi | Mpa | Psi | ||||||

φ13(1/2") | 13±0.5 | 22.2±0.8 | 44±1.06 | 43 | 6230 | 64.5 | 9435 | 86 | 12460 | 230 | 750 |

φ16(5/8") | 16±0.5 | 26±0.8 | 47±1.5 | 38 | 5506 | 57 | 8259 | 76 | 11012 | 260 | 750 |

φ19(3/4") | 19±0.5 | 30±0.8 | 52±1.5 | 34.5 | 4999 | 51.75 | 7498 | 69 | 9998 | 300 | 750 |

φ25(1") | 25±0.8 | 36±0.8 | 59±1.5 | 27.5 | 3984 | 41.25 | 5976 | 55 | 7968 | 360 | 750 |

φ32(5/4") | 32±0.8 | 44±0.8 | 69±2.0 | 20.5 | 2970 | 30.75 | 4455 | 41 | 5940 | 470 | 750 |

φ38(3/2") | 38±1.0 | 76±2.0 | 87.2±5.1 | 17 | 2463 | 25.5 | 3694 | 34 | 4926 | 570 | 750 |

φ51(2") | 51±1.0 | 91±2.0 | 100.7±5.1 | 17 | 2463 | 25.5 | 3695 | 34 | 4926 | 740 | 750 |

3. hydraulic hose Universal Wire-braided DN6

Quick Details

· Place of Origin: Hebei, China (Mainland)

· Brand Name: CMAX/CNBM

· Model Number: GB/T3683-92

Packaging & Delivery

Packaging Details: | hydraulic hose is wrapped with fabrics |

Delivery Detail: | 80000meters/30days |

Specifications

Universal Wire-braided Hydraulic Hose, Q/FLT01-AStandard GB/T3683-92, Temperature range: -40 to +100

Universal Wire-braided Hydraulic Hose

Q/FLT01-AStandard GB/T3683-92

Tube: oil resistant synthetic rubber

Reinforcement: 1 W/B (one high tensile steel wire braid)

Cover: abrasion and weather resistant synthetic rubber

Temperature range: -40 to +100.

4. Drilling Rubber Hose

Quick Details

· Place of Origin: Hebei, China (Mainland)

· Brand Name: CMAX/CNBM

Packaging & Delivery

Packaging Details: | Package: plastic films, then wrapped with fabrics |

Delivery Detail: | According to the Quantity |

Specifications

Drilling hose

DN |

Hose I.D | Wire O.D |

Hose O.D |

Working Pressure | Burst Pressure | Minimum Bend Radius | Weight | Length | |||

inch | mm | mm |

mm | MPa | psi | MPa | psi | mm | kg/m | metres | |

5 | 3/16 | 4.8 | 9.5 | 11.8 | 25.0 | 3630 | 100.0 | 14280 | 89 | 0.19 | 50/100 |

6 | 1/4 | 6.4 | 11.1 | 13.4 | 22.5 | 3270 | 90.0 | 12840 | 102 | 0.21 | 50/100 |

8 | 5/16 | 7.9 | 12.7 | 15.0 | 21.5 | 3120 | 85.0 | 12280 | 114 | 0.24 | 50/100 |

10 | 3/8 | 9.5 | 15.1 | 17.4 | 18.0 | 2615 | 72.0 | 10280 | 127 | 0.33 | 50/100 |

13 | 1/2 | 12.7 | 18.3 | 20.6 | 16.0 | 2320 | 64.0 | 9180 | 178 | 0.41 | 50/100 |

16 | 5/8 | 15.9 | 21.4 | 23.7 | 13.0 | 1890 | 52.0 | 7420 | 203 | 0.45 | 50/100 |

19 | 3/4 | 19.0 | 25.4 | 27.7 | 10.5 | 1530 | 42.0 | 6000 | 241 | 0.58 | 50/100 |

25 | 1 | 25.4 | 33.3 | 35.6 | 8.8 | 1280 | 35.0 | 5020 | 305 | 0.88 | 50 |

32 | 11/4 | 31.8 | 40.5 | 43.5 | 6.3 | 920 | 25.0 | 3600 | 419 | 1.23 | 20/40 |

38 | 11/2 | 38.1 | 46.8 | 50.6 | 5.0 | 730 | 20.0 | 2860 | 508 | 1.51 | 20/40 |

51 | 2 | 50.8 | 60.2 | 64.0 | 4.0 | 580 | 16.0 | 2280 | |||

5. Concrete pump rubber hose

Quick Details

· Place of Origin: Hebei, China (Mainland)

· Brand Name: CMAX/CNBM

Packaging & Delivery

Packaging Details: | Package: plastic films, then wrapped with fabrics |

Delivery Detail: | According to the Quantity |

Specifications

Specifications

High Quality Concrete Pump Delivery Rubber Hose

1.high quality

2.ISO9001:2008

3.reasonable price

1. Material: Black NR and BR synthetic rubber .

2.Reinforcement:Spiral textile/steel wire.

3. Widely application: Schwing PM SANY Zoomlion and other brand concrete pump trucks.

4.Cover:Abrasion resistantant,heat and ozone resistant.

5.Inside diameter:50-152mm

6.Working pressure:8.5 MPA.

7.Detailed specification:

No | Description | ID | OD | Plies | Working Pressure | Burst Pressure | Weight |

1 | 2 inch | 50mm | 70mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 3.5kgs |

2 | 2.5 inch | 63mm | 88mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 4.9kgs |

3 | 3 inch | 76mm | 102mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 6.5kgs |

4 | 4 inch | 100mm | 130mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 9.3kgs |

5 | 5 inch | 125mm | 155mm | 2 or 4 | 8.5MPA 1200PSI | 20MPA 3000PSI | 10.9kgs |

6 | 6 inch | 152mm | 184mm | 2 | 8.5MPA 1200PSI | 20MPA 3000PSI | 13.3kgs |

Production Details

- Q: Can ductile iron pipes be used for underground oil and gas pipelines?

- Yes, ductile iron pipes can be used for underground oil and gas pipelines. Ductile iron is a strong and durable material that can withstand the high pressure and corrosive nature of oil and gas transportation. It has excellent tensile strength and impact resistance, making it suitable for underground applications. Ductile iron pipes are also resistant to external loads, which is important for underground pipelines that may be subject to soil movement or heavy traffic. Furthermore, ductile iron pipes can be easily jointed, allowing for efficient installation and maintenance. However, it is important to consider factors such as soil conditions, environmental factors, and specific project requirements before choosing ductile iron pipes for underground oil and gas pipelines.

- Q: Are ductile iron pipes resistant to external loads?

- Generally, external loads pose little challenge to ductile iron pipes. Ductile iron, a variant of cast iron, undergoes treatment with magnesium and cerium additives to enhance its flexibility and durability. As a result, these pipes possess the ability to endure substantial external pressure and stress without succumbing to cracks or fractures. Ductile iron pipes find extensive implementation in scenarios where heavy loads are anticipated, including underground water distribution systems, sewer lines, and industrial pipelines. Their exceptional resistance to external loads has been thoroughly validated, establishing them as a dependable option for diverse infrastructure ventures.

- Q: What are the different types of joints used with ductile iron pipe?

- The different types of joints commonly used with ductile iron pipe include push-on joints, mechanical joints, restrained joints, flanged joints, and welded joints. Each type of joint offers different benefits and is used depending on the specific requirements of the installation.

- Q: Can ductile iron pipes be used for drainage systems in airports?

- Yes, ductile iron pipes can be used for drainage systems in airports. Ductile iron pipes are known for their durability, strength, and resistance to corrosion, making them suitable for various applications, including drainage systems. They are capable of withstanding heavy loads, which is important in airports due to the constant movement of aircraft and vehicles. Ductile iron pipes are also flexible, allowing for easy installation and modification when necessary. Additionally, they have a long lifespan, reducing the need for frequent maintenance or replacement. Therefore, ductile iron pipes can be a reliable choice for drainage systems in airports, ensuring efficient water flow and preventing water accumulation, which is crucial for maintaining safe and operational airport facilities.

- Q: How do ductile iron pipes handle ground movement in earthquake-prone areas?

- Ductile iron pipes are designed to withstand ground movement in earthquake-prone areas due to their inherent strength and flexibility. The ductile nature of the iron allows the pipes to deform and absorb the seismic energy without breaking or fracturing. This ensures their durability and ability to maintain water supply and drainage systems even during seismic events. Additionally, ductile iron pipes have superior joint integrity, which further enhances their resistance to ground movement and minimizes the risk of leaks or pipe failure.

- Q: Can ductile iron pipes be used for wastewater pumping stations?

- Indeed, wastewater pumping stations can utilize ductile iron pipes. With their remarkable strength and durability, ductile iron pipes are well-suited for transporting wastewater and effectively managing the immense pressures and corrosive properties of sewage. Furthermore, the smooth interior surface of ductile iron pipes prevents blockages and facilitates the efficient flow of wastewater. Moreover, these pipes exhibit resistance towards external forces like soil displacement or heavy vehicular movement, thereby establishing themselves as a dependable option for wastewater pumping stations.

- Q: What does "K8" mean in ductile iron pipe grades?

- K9 is GB, K10 is specially customized, K8... Strictly speaking, it is not up to standard, standard length, wall thickness and so on.. Many workshops, grades of factory products, such as K9, standard length 6.15M, K8 is 6M, wall thickness from the beginning of DN100, are thin on the point.

- Q: How does ductile iron pipe perform in extreme weather conditions?

- Ductile iron pipe performs exceptionally well in extreme weather conditions. Its superior strength and durability make it resistant to cracking, breaking, or corroding, even in harsh environments. This stability allows it to withstand extreme temperatures, high winds, heavy rain, and even seismic activities, ensuring reliable performance and longevity.

- Q: How do ductile iron pipes handle seismic movements?

- Ductile iron pipes are renowned for their exceptional capacity to handle seismic movements, owing to their distinctive properties and construction. This renders them remarkably resistant to stress and deformation caused by ground vibrations during earthquakes. One of the primary merits of ductile iron pipes lies in their superior tensile strength, enabling them to endure substantial forces without succumbing to breakage or rupture. When seismic movements occur, these pipes exhibit flexibility and absorb the energy generated by the ground vibrations, thereby minimizing the risk of damage or failure. Moreover, ductile iron pipes possess exemplary resilience, allowing them to revert to their original shape after being subjected to external forces. This characteristic empowers the pipes to adapt to ground movements during earthquakes, effectively diminishing the likelihood of fractures or leaks. Furthermore, ductile iron pipes boast considerable ductility, enabling them to deform without fracturing. This attribute proves crucial during seismic events, as it enables the pipes to absorb the energy generated by ground vibrations by deforming and subsequently returning to their original shape once the seismic activity subsides. In order to further enhance their capacity to handle seismic movements, ductile iron pipes are frequently designed and installed with flexible joints. These joints grant the pipes the ability to move and adjust to ground movements, offering additional safeguards against damage or failure. In conclusion, ductile iron pipes have demonstrated their extraordinary reliability and resilience in withstanding seismic movements. Their combination of high tensile strength, resilience, and ductility make them an optimal choice for regions prone to earthquakes, ensuring the safety and durability of fluid transportation systems.

- Q: Can ductile iron pipes be used in tunneling or microtunneling projects?

- Yes, ductile iron pipes can be used in tunneling or microtunneling projects. Ductile iron pipes are known for their durability, strength, and resistance to corrosion, making them suitable for underground applications. They can handle the pressure and load requirements of tunneling projects and provide reliable and long-lasting performance.

Send your message to us

Ductile Iron Pipe With Competitive Price ISO2531/EN545

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords