Ductile Iron Pipe ISO2531and EN545 Standards

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 300000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Ductile Iron Pipe Description :

1 |

Type:

| The T-type Joint Pipe (Push-on) |

The K-type Joint Pipe | ||

The Self-Restrained Joint Pipes | ||

2 | Standard: | ISO2531, EN545, EN598, etc |

3 | Size: | DN80~2600mm |

4 | Material: | Ductile Cast Iron GGG50 |

5 | Pressure: | PN10, PN16, PN25,PN40 |

6 | Class: | K9, K8, C25, C30, C40 |

7 | Length: | 6m, cut to 5.7m |

8 | Application: | Water supply project, drainage, sewage, irrigation, water pipeline. |

9 | Certificate: | ISO9001, BV, WRAS, SGS |

10

| Internal Coating: | a). Portland cement mortar lining |

b). Sulphate Resistant cement mortar lining | ||

c). High-Aluminum cement mortar lining | ||

d). Fusion bonded epoxy coating | ||

e). Liquid epoxy painting | ||

f). Black bitumen painting | ||

11 | External Coating: | a). zinc+bitumen(70microns) painting |

b). Fusion bonded epoxy coating | ||

c). Zinc-aluminum alloy +liquid epoxy painting | ||

12 | Packing: | Bundles, in bulk |

Note: The coating can also be accordance with customers' requirements. | ||

2. Ductile Iron Pipe Main Features:

- For potable water supply

- High strength

- Long lifespan

- Good corrosion resistance

- Easy installation

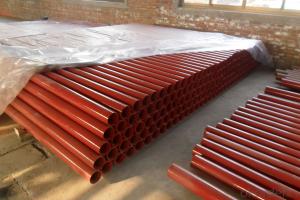

3.Ductile Iron Pipe Images:

4.Ductile Iron Pipe Specification:

1.Standard:ISO2531,EN545,EN598

2.Effective Length:6m/5.7m

3.Internal Lining :Cement mortar, Cement mortar Plus Epoxy

4.External coating:Zinc Primer Plus Bitumen or PE

5. Shipment: By bulk ship or 20'/40' container

6. Rubber: NBR, SBR, EPDM according to ISO4633/EN681.1

7.Quick Delivery

5.FAQ:

Here some questions always been asked

1.For Price CIF CFR FOB CPT and so on both ok for us

2.For Delivery we must try us best to send goods to you asap

3.For Package all standard seaworthy package

4.For Payment, T/T L/C which convenience for you will be ok

- Q: Can ductile iron pipe be used for directional drilling?

- Yes, ductile iron pipe can be used for directional drilling. Directional drilling is a technique used to install underground pipes, cables, and conduits in a curved or horizontal path. Ductile iron pipes are known for their high strength and flexibility, making them suitable for this method. The pipes can be easily bent and maneuvered during the drilling process, allowing for the installation of pipelines in challenging terrains or crossing obstacles such as rivers, highways, and buildings. Additionally, ductile iron pipes have excellent resistance to corrosion, making them a durable and reliable choice for directional drilling projects.

- Q: Can ductile iron pipe be used for wastewater treatment plants?

- Ductile iron pipe is indeed applicable for wastewater treatment plants. This material is robust and long-lasting, displaying resistance against both corrosion and abrasion. Given the severe and corrosive conditions commonly present in such facilities, ductile iron pipe is frequently chosen. Its exceptional hydraulic performance further enables efficient and effective transportation of wastewater. Moreover, the simple installation and maintenance process of ductile iron pipe make it a practical preference for wastewater treatment plants. Ultimately, ductile iron pipe proves to be a dependable and economical alternative for wastewater treatment purposes.

- Q: Are ductile iron pipes suitable for wastewater treatment plants?

- Ductile iron pipes are highly suitable for wastewater treatment plants. They possess exceptional strength and durability, making them resistant to corrosion. Consequently, these pipes are an excellent choice for managing wastewater, which often contains corrosive elements. Moreover, ductile iron pipes boast remarkable tensile strength and can endure high pressure, critical for the transportation of wastewater in treatment plants. The flexibility of these pipes also permits easy installation and maintenance, ultimately reducing both cost and time required for wastewater treatment plants. In summary, ductile iron pipes are extensively utilized in wastewater treatment plants due to their durability, resistance to corrosion, and their ability to handle the challenging conditions present in such facilities.

- Q: Can ductile iron pipes be used for fire protection systems?

- Fire protection systems can utilize ductile iron pipes. Ductile iron, a form of cast iron, possesses both strength and flexibility, making it suitable for various applications, including fire protection systems. It boasts excellent mechanical properties, such as high tensile strength and impact resistance, which are essential for withstanding the pressures and stresses that can arise during fire suppression efforts. Ductile iron pipes are renowned for their durability and long lifespan, which is crucial for reliable and functional fire protection systems. They have a longer lifespan compared to materials like PVC or galvanized steel and are less susceptible to corrosion. This is particularly important for fire protection systems, as they must remain operational even after extended periods of inactivity. Additionally, ductile iron pipes exhibit exceptional fire resistance. They can withstand high temperatures without compromising their structural integrity, ensuring the fire protection system remains intact and functional during fire emergencies. This is pivotal for ensuring the safety of occupants and minimizing property damage. Furthermore, ductile iron pipes are compatible with a wide range of fittings, valves, and accessories commonly used in fire protection systems. This facilitates easy installation and integration into existing fire suppression networks. In conclusion, ductile iron pipes are a reliable and suitable choice for fire protection systems due to their strength, durability, fire resistance, and compatibility with other system components.

- Q: Are there any specific standards or regulations for ductile iron pipe?

- Yes, there are specific standards and regulations for ductile iron pipe. Ductile iron pipe is commonly used in water and wastewater systems due to its strength and durability. The most widely recognized standard for ductile iron pipe is the American Water Works Association (AWWA) C151 standard. This standard covers the minimum requirements for ductile iron pipe, including materials, dimensions, tolerances, and testing methods. It also provides guidelines for the manufacturing, installation, and maintenance of ductile iron pipe systems. In addition to the AWWA C151 standard, there are also other standards and regulations that govern the use of ductile iron pipe in different countries. For example, in Europe, ductile iron pipe is governed by the EN 545 and EN 598 standards, which specify the requirements for ductile iron pipes and fittings used in water supply and wastewater systems. Furthermore, government agencies such as the Environmental Protection Agency (EPA) in the United States may have specific regulations and guidelines for the use of ductile iron pipe in certain applications, such as drinking water systems. It is crucial for manufacturers, contractors, and engineers involved in the design, installation, and maintenance of ductile iron pipe systems to ensure compliance with these standards and regulations. This helps to ensure that ductile iron pipe is manufactured to the highest quality standards, and that it is installed and maintained properly to ensure its longevity and reliability in water and wastewater systems.

- Q: Can ductile iron pipe be used for hydroelectric power generation?

- Yes, ductile iron pipe can be used for hydroelectric power generation. Ductile iron pipes are known for their strength, durability, and resistance to corrosion, making them suitable for various applications including the transportation of water in hydroelectric power plants.

- Q: Can ductile iron pipes be used for trenchless installations?

- Indeed, trenchless installations can utilize ductile iron pipes. Horizontal directional drilling (HDD) and pipe bursting techniques have gained considerable popularity as alternatives to the conventional open-cut trenching method for underground utility installations. Ductile iron pipes possess the necessary qualities of strength, durability, and flexibility, rendering them suitable for trenchless installations. They can endure the formidable forces encountered during HDD and pipe bursting operations without jeopardizing their structural integrity. Moreover, ductile iron pipes exhibit remarkable resistance to corrosion, establishing them as a dependable option for trenchless applications.

- Q: Can ductile iron pipes be used for firefighting systems?

- Yes, ductile iron pipes can be used for firefighting systems. Ductile iron is a strong and durable material that can withstand high pressures and extreme temperatures, making it suitable for transporting water in firefighting systems. Its ability to resist corrosion and withstand external loads also ensures the long-term reliability and performance of the pipes. Additionally, ductile iron pipes have excellent fire resistance properties, as they do not burn, emit toxic fumes, or contribute to the spread of fire. Therefore, ductile iron pipes are a reliable and commonly used choice for firefighting systems due to their strength, durability, and fire resistance.

- Q: Can ductile iron pipe be used for water distribution systems in cold climates?

- In cold climates, ductile iron pipe is an ideal choice for water distribution systems. This type of pipe is renowned for its strength and durability, making it suitable for a range of applications, including water distribution. Its exceptional ability to withstand external forces, such as freezing temperatures, frost heaving, and ground movement, is particularly advantageous in cold climates. Furthermore, ductile iron pipe exhibits a high tolerance for temperature fluctuations, ensuring its reliability for water transportation even in extreme cold conditions. Additionally, its corrosion-resistant properties guarantee the long-lasting and dependable performance of the pipe, even in harsh environments. Therefore, when it comes to water distribution systems in cold climates, ductile iron pipe is the optimal choice.

- Q: Can ductile iron pipes be used for stormwater drainage systems?

- Indeed, stormwater drainage systems can utilize ductile iron pipes. These pipes are renowned for their strength, durability, and resistance to corrosion, rendering them appropriate for various applications, including stormwater drainage. They possess the capacity to accommodate substantial water flow and endure heavy traffic loads, making them a reliable selection for stormwater management. Moreover, ductile iron pipes exhibit exceptional joint performance, guaranteeing a watertight and secure connection, a critical aspect in preventing leaks and preserving the integrity of the stormwater drainage system. All in all, due to their sturdiness, longevity, and ability to withstand the challenging conditions typically associated with stormwater management, ductile iron pipes present a viable choice for stormwater drainage systems.

Send your message to us

Ductile Iron Pipe ISO2531and EN545 Standards

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 300000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords