Flange Pipe

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Metric Ton pc

- Supply Capability:

- 300000 Metric Tons per Year pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

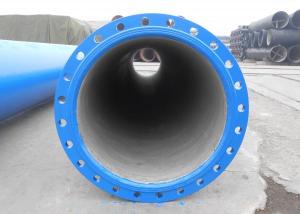

General introduction of Flange Pipe

•Material: Ductile Cast Iron

•Size Range: DN 80mm to DN 2000mm

•Unit Effective Length: 5.7m or 6m or negotiable

•Manufacture Standard: ISO 2531:1998/ EN 545:2006/EN 598:2007

•Annual capacity: 300,000 tons

• Internal lining: cement mortar lining comply with ISO4179.

External coating: sprayed metallic Zinc coating (min.130g/m2) according to ISO8179 + bitumen painting (min.70μm) according to BS3416.

Gasket: Matched 100% natural rubber gasket in accordance with ISO4633.

•Special requirements on external coating and internal lining can be applied

•We also provide accessories such as SBR/EPDM rubber gaskets, lubricant paste, pipe caps, PE sleeves, etc.

Features of Flange Pipes:

Ductile cast iron, also called ductile iron, spheroidal graphite iron, or nodular cast iron, is a type of cast iron invented in 1943. While most varieties of cast iron are brittle, ductile cast iron is much more flexible and elastic, due to its nodular graphite inclusions.

· Ductile Iron Pipe offers proven reliability and the quality.

· It is quick and easy installation.

· The ductile iron pipe has high pressure capability.

· Available in sizes DN80 – DN2000

· Both T Type (Push-on Joint) and K Type (Mechanical Joint) are available

· Match 100% Natural rubber / SBR / EPDM rubber gaskets

Application:

Much of the production of ductile iron is in the form of ductile cast iron pipe, used for water supply and sewerage design. Ductile iron pipe is stronger and easier to tap, requires less support and provides greater flow area compared with pipes made from other materials like PVC, concrete, polyethylene or steel.

Types of Flange Pipe:

Flange pipes with screwed-on flanges, Flanged pipes with cast-on flanges, Flanged pipes with welded-on flanges are available

Flange pipes with screwed-on flanges, K9 K10 DN80-DN600, Length to be specified

Flange pipes with cast-on flanges, K12 DN1200-2000, L≤4000mm

Flange pipes with welded-on flanges, K9 K10, DN80-DN1000, Length to be specified

Nominal Diameter of Flange Pipe:

|

Nominal Diameter DN |

Body |

| ||||||||

|

k=9 |

k=10 |

k=12 |

Each Flange | |||||||

|

e mm |

kg/m |

e mm |

kg/m |

e mm |

kg/m |

PN10 |

PN16 |

PN25 |

PN40 | |

|

80 |

6 |

12.2 |

6 |

12.2 |

7 |

14.1 |

3.6 |

3.6 |

3.5 |

3.5 |

|

100 |

6.1 |

15.1 |

6.1 |

15.1 |

7.2 |

17.7 |

4.2 |

4.2 |

4.5 |

4.5 |

|

150 |

6.3 |

22.8 |

6.5 |

23.5 |

7.8 |

28 |

6.3 |

6.3 |

7.1 |

9.2 |

|

200 |

6.4 |

30.6 |

7 |

33.3 |

8.4 |

39.7 |

8.8 |

8.6 |

10.4 |

15.7 |

|

250 |

6..8 |

40.2 |

7.5 |

44.3 |

9 |

52.8 |

12 |

11.8 |

15.3 |

25.4 |

|

300 |

7.2 |

50.8 |

8 |

56.3 |

9.6 |

67.3 |

16.8 |

16.6 |

20.8 |

36.3 |

|

350 |

7.7 |

63.2 |

8.5 |

69.6 |

10.2 |

83.1 |

23 |

25.5 |

29.0 |

- |

|

400 |

8.1 |

75.5 |

9 |

83.7 |

10.8 |

100 |

26.5 |

31 |

37.4 |

- |

|

500 |

9 |

104.3 |

10 |

115.6 |

12 |

138.2 |

41 |

54 |

54.5 |

- |

|

600 |

9.9 |

137.1 |

11 |

152 |

13.2 |

181.8 |

56 |

79.8 |

79.1 |

- |

|

700 |

10.8 |

173.9 |

12 |

193 |

14.4 |

230.8 |

72.5 |

84.2 |

- |

- |

|

800 |

11.7 |

215.2 |

13 |

238.7 |

15.6 |

285.5 |

102 |

117 |

- |

- |

|

900 |

12.6 |

260.2 |

14 |

288.7 |

16.8 |

345.4 |

118.5 |

137.5 |

- |

- |

|

1000 |

13.5 |

309.3 |

15 |

343.2 |

18 |

410.6 |

135 |

169.4 |

- |

-- |

|

1200 |

15.3 |

420.1 |

17 |

466.1 |

20.4 |

557.8 |

180 |

235 |

- |

- |

|

1400 |

17.1 |

547.2 |

19 |

607.2 |

22.8 |

726.8 |

253 |

301 |

- |

- |

|

1600 |

18.9 |

690.3 |

21 |

766 |

25.2 |

916.9 |

- |

- |

- |

- |

|

1800 |

20.7 |

850.1 |

23 |

943.4 |

27.6 |

1129.3 |

- |

|

- |

- |

|

2000 |

22.5 |

1026.3 |

25 |

1139 |

30 |

1363.4 |

- |

- |

- |

- |

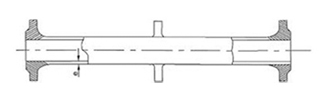

Double Flange Pipes

Double Flanged Pipes

We are involved in the manufacture and supply of the ductile iron double flanged pipe. We manufacture these with the premium quality raw materials. Our pipes ensure high durability and strength. Our range of Double Flanged Pipes caters to various industrial requirements. We offer these Double Flanged Pipes in different sizes and lengths in order to meet the various requirements of our esteemed clients.

K12

Size: DN80-1200

|

Nominal Diameter DN |

L |

Mass(kg) | |

|

Inch size end |

Metric size end | ||

|

3 |

80 |

150 |

6.8 |

|

3 |

80 |

200 |

7.5 |

|

3 |

80 |

250 |

8.2 |

|

4 |

100 |

250 |

10.8 |

|

5 |

150 |

250 |

15.4 |

|

6 |

150 |

250 |

16.3 |

|

7 |

200 |

250 |

21.5 |

|

8 |

200 |

250 |

23.0 |

|

9 |

250 |

250 |

30.0 |

|

10 |

250 |

250 |

34.5 |

|

12 |

300 |

250 |

44.0 |

|

14 |

350 |

250 |

59.0 |

|

15 |

400 |

250 |

65.0 |

|

16 |

400 |

250 |

71.0 |

|

18 |

450 |

250 |

89.5 |

|

20 |

500 |

250 |

115.0 |

|

21 |

500 |

350 |

133.0 |

|

24 |

600 |

300 |

178.0 |

|

27 |

700 |

500 |

261.8 |

|

30 |

700 |

500 |

289.0 |

|

30 |

800 |

500 |

317.0 |

|

33 |

800 |

500 |

356.0 |

|

36 |

900 |

500 |

420.0 |

|

42 |

1000 |

500 |

514.0 |

|

42 |

1100 |

500 |

575.0 |

|

48 |

1200 |

500 |

718.0 |

Photo Show of Flange Pipe:

- Q: What is the lifespan of ductile iron pipes?

- The lifespan of ductile iron pipes can vary depending on various factors such as the quality of the pipes, the installation conditions, and the environment in which they are used. However, on average, ductile iron pipes have a lifespan of around 50 to 100 years. This makes them a durable and long-lasting option for water and sewer infrastructure. With proper maintenance and regular inspections, ductile iron pipes can continue to function effectively and efficiently for several decades. It is important to note that factors like corrosion, soil conditions, and water chemistry can impact the lifespan of these pipes, so monitoring and addressing these issues can help extend their lifespan.

- Q: How do ductile iron pipes handle traffic vibrations?

- Ductile iron pipes are highly resistant to traffic vibrations due to their inherent strength and flexibility. These pipes have the ability to absorb and dissipate the energy generated by traffic vibrations, minimizing any potential damage or stress on the pipes. Additionally, their sturdy construction and high tensile strength make them less susceptible to cracking or breaking under the impact of traffic-induced vibrations. Overall, ductile iron pipes provide excellent performance and durability in handling traffic vibrations.

- Q: How do ductile iron pipes handle ground settlement?

- Ductile iron pipes are highly effective in handling ground settlement due to their inherent flexibility and resistance to deformation. The unique properties of ductile iron, including its high tensile strength and elongation capacity, make it an ideal material for withstanding ground movement. When ground settlement occurs, which is the downward movement of soil or sediment, ductile iron pipes have the ability to flex and adjust to the shifting ground without fracturing. The pipes can absorb the stress caused by the settlement and distribute it evenly along their length, minimizing the risk of cracks or breaks. Furthermore, ductile iron pipes are designed with a bell and spigot joint system, which allows for slight movement and rotation at the joints. This feature enables the pipes to accommodate ground settlement by absorbing any misalignment or shifting of the surrounding soil. Additionally, ductile iron pipes have a higher load-bearing capacity than other materials like PVC or HDPE. This means that they can withstand heavier loads and pressures from the surrounding soil, reducing the risk of pipe failure or collapse during ground settlement. In conclusion, ductile iron pipes are well-suited to handle ground settlement due to their flexibility, resistance to deformation, and ability to distribute stress evenly. Their unique properties ensure that they can withstand the challenges posed by shifting ground conditions, making them a reliable choice for underground infrastructure projects.

- Q: Can ductile iron pipe be used for directional drilling?

- Indeed, it is possible to utilize ductile iron pipe for directional drilling. This method involves the installation of pipes, cables, and conduits beneath the ground in a curved or horizontal trajectory. Ductile iron pipes are renowned for their exceptional strength and flexibility, rendering them apt for this technique. They can be effortlessly bent and maneuvered while drilling, thereby enabling the installation of pipelines in demanding terrains and the traversing of obstacles such as rivers, highways, and buildings. Moreover, the corrosion resistance of ductile iron pipes is superb, thereby ensuring their durability and reliability for directional drilling endeavors.

- Q: How are ductile iron pipes protected against interior corrosion?

- Cement mortar lining is utilized to protect ductile iron pipes against interior corrosion. This process involves the application of a layer of cement mortar to the inner surface of the pipe. By acting as a protective barrier, the cement mortar prevents the corrosive elements in the water or fluid from directly contacting the iron material. To apply the cement mortar lining, the interior surface of the ductile iron pipe is initially prepared by removing any loose scale or debris. Next, a mixture of cement, sand, and water is prepared to create a paste-like consistency. Skilled workers can then manually apply this mixture to the interior surface of the pipe or use a spinning machine. Once the cement mortar lining is applied, it must cure for a specific period, typically around 24 hours. During this curing process, the cement mortar hardens and forms a dense protective layer on the pipe's inner surface. The cement mortar lining provides several advantages in safeguarding ductile iron pipes against corrosion. It creates a smooth and continuous surface that prevents direct contact between the water or fluid and the iron material, thus reducing the risk of corrosion. Additionally, the lining helps to minimize friction within the pipe, thereby enhancing flow efficiency. It is crucial to regularly inspect and maintain the cement mortar lining to ensure its effectiveness in preventing corrosion. Over time, the lining may develop cracks or deteriorate, compromising its protective properties. Therefore, periodic inspections are necessary to repair or replace the lining as required, ensuring the integrity of the ductile iron pipes and preventing interior corrosion.

- Q: Are ductile iron pipes suitable for pressure sewer systems?

- Yes, ductile iron pipes are suitable for pressure sewer systems. Ductile iron pipes have been widely used in various applications, including pressure sewer systems, due to their high strength and durability. These pipes are able to withstand high pressure and provide a reliable and long-lasting solution for transporting sewage under pressure. Ductile iron pipes also have excellent corrosion resistance, which is crucial in sewer systems where they are exposed to various chemicals and contaminants. They are resistant to both internal and external corrosion, ensuring that the pipes remain intact and functional over time. Furthermore, ductile iron pipes have a smooth internal surface, which helps to minimize friction and improve the flow capacity of the sewer system. This ensures that the pipes can handle the required flow rates and prevent any blockages or backups. In addition to their strength and corrosion resistance, ductile iron pipes are also known for their ease of installation. They can be easily cut and joined using a variety of methods, making them a convenient choice for pressure sewer systems. Overall, ductile iron pipes are a suitable and reliable choice for pressure sewer systems due to their high strength, corrosion resistance, smooth internal surface, and ease of installation.

- Q: What are the different coatings available for ductile iron pipe?

- Ductile iron pipes offer a range of coating options, each with their own advantages and protective qualities for different uses. Some commonly utilized coatings are as follows: 1. Cement Mortar Lining: By applying a layer of cement mortar to the pipe's interior surface, this coating provides excellent resistance against corrosion and abrasion. It is ideal for transporting water and sewage. 2. Bituminous Coating: Consisting of asphalt or coal tar pitch applied to the pipe surface, bituminous coatings offer effective protection against corrosion. They are commonly used for underground pipes in water and wastewater systems. 3. Fusion-Bonded Epoxy (FBE) Coating: FBE coatings are created by electrostatically applying an epoxy powder layer to the pipe surface, which is then cured at high temperatures. This coating offers exceptional corrosion resistance and is suitable for harsh environments and corrosive substances. 4. Polyurethane Coating: Polyurethane coatings provide excellent resistance against abrasion, impact, and corrosion. They are often used for pipes exposed to abrasive materials or requiring additional protection against external damage. 5. Zinc Coating: Also known as galvanized coatings, zinc coatings involve applying a layer of zinc to the pipe's surface. This coating offers excellent corrosion protection, making it suitable for pipes exposed to moisture and aggressive environments. 6. Polyethylene Encasement: Polyethylene encasement involves wrapping the pipe with a layer of polyethylene film or tape. This coating acts as a physical barrier against corrosion and is commonly used in conjunction with other coatings for added protection. To determine the most appropriate coating for ductile iron pipes, it is crucial to consider the specific requirements of the application, such as the type of fluid being transported and the environmental conditions.

- Q: Are there any specific standards or specifications for ductile iron pipes?

- Ductile iron pipes have specific standards and specifications that must be adhered to. The American Water Works Association (AWWA) and the International Organization for Standardization (ISO) are responsible for establishing the most commonly used standards for these pipes. AWWA has developed the AWWA C151 standard, which covers everything from design and manufacturing to testing, installation, and maintenance requirements for ductile iron pipes used in water and wastewater applications. This standard outlines the materials, dimensions, and mechanical properties of the pipes, as well as the necessary coatings and linings. Similarly, ISO has created the ISO 2531 standard, which provides guidelines for the design, manufacturing, testing, and installation of ductile iron pipes in water and wastewater systems. This standard addresses various aspects, including dimensions, mechanical properties, coatings, and linings. In addition to these well-known standards, there may be other regional or national standards that are specific to certain countries or regions. These standards typically align with the AWWA and ISO standards or may have additional requirements that are specific to local conditions or regulations. Compliance with these standards ensures that ductile iron pipes meet the required quality and performance standards. It also promotes the interoperability and compatibility of ductile iron pipes across different systems and countries, which in turn enables reliable and efficient water distribution and wastewater management.

- Q: What are the different accessories available for ductile iron pipe?

- There are several accessories available for ductile iron pipes that help enhance their functionality and ensure efficient operation. Some of the common accessories include: 1. Flange Adapters: These accessories help connect ductile iron pipes to other pipe materials or equipment such as valves, pumps, or fittings. Flange adapters provide a secure and leak-proof connection. 2. Mechanical Joint Fittings: Mechanical joint fittings are used to join ductile iron pipes together. They consist of a gland, gland follower, and bolts, providing a flexible and easily adjustable connection. 3. Restrained Joint Fittings: These fittings are used in applications where the pipe needs to be restrained to prevent movement or separation. They ensure stability and prevent potential damage from external forces or pressure. 4. Thrust Blocks: Thrust blocks are concrete structures used to resist the thrust generated by internal pressure in ductile iron pipes. They prevent pipe movement and maintain stability. 5. Valve Boxes: Valve boxes provide protection and easy access to valves installed along the ductile iron pipeline. They are typically made of cast iron or polymer materials and are available in various sizes and designs. 6. Hydrant Assemblies: Hydrant assemblies are installed for fire protection purposes. They consist of a ductile iron pipe, a hydrant valve, and a fire hydrant. These assemblies are crucial for quick access to water during firefighting operations. 7. Tapping Saddles: Tapping saddles are used to create a branch connection on a ductile iron pipe without interrupting the flow. They provide a convenient way to install service connections, valves, or meters. 8. Pipe Restraints and Supports: These accessories are used to secure ductile iron pipes to structures or prevent excessive movement. They help maintain proper alignment, prevent sagging, and ensure the structural integrity of the pipeline. 9. Pipe Repair Clamps: In case of pipe damage or leaks, repair clamps provide a quick and temporary solution. These clamps are designed to fit around the damaged area and provide a tight seal to stop the leak. 10. Gaskets and Seals: Gaskets and seals are essential accessories to ensure leak-free connections. They are available in various materials, such as rubber or synthetic compounds, and are used to create a watertight seal between pipes or fittings. These are just a few examples of the accessories available for ductile iron pipes. The selection of accessories depends on the specific requirements of the project, and consulting with a pipe supplier or engineer is recommended to ensure the right accessories are chosen for the application.

- Q: Is the crankshaft material forged or ductile iron?

- Cast iron can not be forged, only steel, malleable iron can not be forged, only the crankshaft is particularly hot, can not meet the strength of the hardening when forging

1. Manufacturer Overview

| Location | Henan, China |

| Year Established | 1958 |

| Annual Output Value | Below US$1 Million |

| Main Markets | Mid East, Africa, South Asia, Eastern Asia |

| Company Certifications | ISO 9001:2008;ISO2531:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 1% - 10% |

| No.of Employees in Trade Department | 3000 People |

| Language Spoken: | English; Chinese; Spain; Alabic |

| b) Factory Information | |

| Factory Size: | Above 150,000 square meters |

| No. of Production Lines | Above 6 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Flange Pipe

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Metric Ton pc

- Supply Capability:

- 300000 Metric Tons per Year pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords