DI Pipes in Water project,ductile iron double flanged taper with concentric

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

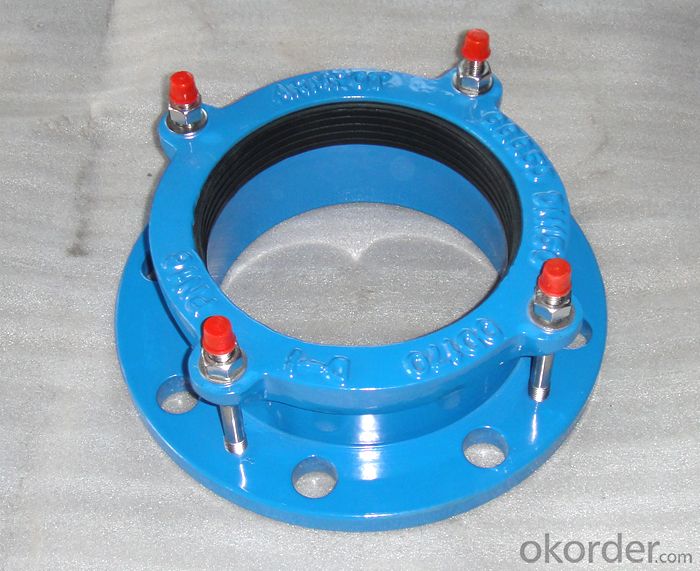

DI Pipes in Water project,ductile iron double flanged taper with concentric

ISO 2531 / EN 545 / EN 598 / GB 13295

Specifications

Flanged Fittings

| Material | |

| Ductile iron grade 500-7 / 450-12 in accordance with ISO 1083 | |

| Flange | |

| P 10, PN16 or PN25 drilling in accordance with ISO 7005-2 / EN 1092-2 | |

| Fluid Temperature | |

| 0°C-50°C, excluding frost | |

| Coating | |

| External coatings | Internal coatings |

| zinc + bitumen painting liquid epoxy resin painting | cement mortar lining liquid epoxy resin painting |

| Reference Rules | |

| Dimensions and testing in accordance with ISO 2531 / EN 545 | |

| Use | |

| Jointed by the bolts, nuts and sealed by the gaskets. | |

China National Building Materials Group Corporation (CNBM) was established in 1984 with approval from the State Council, and then became a Central Enterprise under direct supervision of State-owned Assets Supervision and Administration Commission of the State Council in 2003.

Upholding the philosophy of “Making Best Use of Resources to Serve Construction”, and vigorously carrying out such strategies as “technical innovation”, “internationalization of building materials”, and “building strength with talents”, CNBM is the largest comprehensive building materials industry group in China that integrates scientific research, manufacturing and logistics into one entity, and consists of four business platforms, i.e. industry, technology, complete set of equipment, and trading & logistics. As of the end of 2009, CNBM’s total assets exceeded RMB 110 billion, with 100,000 employees, and 20 companies under direct management with 100% share control or majority control, among which 6 were listed companies, including 2 overseas listed.

CNBM practices the parent-subsidiary management system, and is one of those wholly state-owned enterprises carrying out the pilot trial of Board of Directors system and innovation system. As the strategic center, decision center, resources center, and policy & culture center, our Group exercises its right as a contributor. Whereas, our sub-groups functioning as business platforms, are mandated to construct the profit center based on their core competences to enlarge brand awareness and increase market share.

- Q: Can ductile iron pipes be used for mining applications?

- Yes, ductile iron pipes can be used for mining applications. Ductile iron pipes possess excellent mechanical properties, such as high tensile strength, impact resistance, and durability, making them suitable for various demanding environments, including mining operations. These pipes can withstand heavy loads and pressures, making them ideal for transporting water, slurry, and other fluids used in mining processes. Additionally, ductile iron pipes have a smooth internal surface, minimizing friction and facilitating efficient flow of materials. Hence, they are widely used in applications such as dewatering, tailings disposal, and transporting corrosive or abrasive materials in the mining industry. Overall, ductile iron pipes are a reliable and cost-effective choice for mining applications due to their strength, durability, and suitability for demanding conditions.

- Q: How do ductile iron pipes handle water hammer in high-rise buildings?

- Ductile iron pipes are known for their durability and strength, making them an excellent choice for handling water hammer in high-rise buildings. Water hammer is a common phenomenon that occurs when the flow of water in a pipe is suddenly stopped or changed direction, resulting in a pressure surge. This can cause significant stress on the pipes and potentially lead to damage or failure. Ductile iron pipes are designed to withstand high-pressure situations, making them highly resistant to water hammer. They have a high tensile strength and can handle the sudden changes in pressure without deforming or fracturing. This is particularly important in high-rise buildings where the water supply needs to be delivered to various floors with different pressures. Moreover, ductile iron pipes have excellent corrosion resistance properties, which further enhances their ability to handle water hammer. Corrosion can weaken pipes over time and make them more susceptible to failure during pressure surges. However, the corrosion resistance of ductile iron pipes ensures that they remain structurally sound even in high-pressure situations. Additionally, the flexibility of ductile iron pipes allows them to absorb and dissipate the energy generated by water hammer. This helps to minimize the impact on the overall system and reduce the potential for damage. The ability to absorb energy also helps to reduce noise and vibrations associated with water hammer, creating a more comfortable and efficient water supply system. In conclusion, ductile iron pipes are well-equipped to handle water hammer in high-rise buildings. Their strength, corrosion resistance, and flexibility make them a reliable choice for delivering water under varying pressures without compromising the integrity of the system.

- Q: Are ductile iron pipes suitable for bridge crossings or crossings under roadways?

- Yes, ductile iron pipes are suitable for bridge crossings or crossings under roadways. They possess high strength and durability, making them capable of withstanding heavy loads and traffic conditions. Additionally, their flexibility and resistance to external pressures make them an ideal choice for such applications, ensuring long-lasting and reliable performance.

- Q: Are ductile iron pipes suitable for installation in areas with high groundwater table?

- Yes, ductile iron pipes are suitable for installation in areas with high groundwater table. Ductile iron pipes have excellent corrosion resistance and are highly durable, making them resistant to the corrosive effects of groundwater. Additionally, their strong and flexible nature allows them to withstand external pressure caused by high groundwater levels without compromising their structural integrity.

- Q: What are the different joint restraint systems available for ductile iron pipe?

- There are several different joint restraint systems available for ductile iron pipe. These systems are designed to prevent movement and separation of the pipe at the joints, ensuring a secure and leak-free connection. Some of the common joint restraint systems for ductile iron pipe include: 1. Mechanical Joint Restraint: This system consists of a mechanical joint adapter and a restraining gland that provides axial restraint. The joint adapter is bolted to the pipe, while the restraining gland is bolted to the adjacent pipe or structure, preventing any movement. 2. Push-on Joint Restraint: In this system, a push-on joint is used along with a restraining gland that is bolted to the pipe or structure. The gland provides axial restraint by gripping the pipe and preventing it from moving. 3. Flex-Ring Joint Restraint: This system utilizes a flexible rubber ring that is installed inside the pipe's bell. The ring provides radial restraint by expanding against the pipe, ensuring a tight and secure connection. 4. Harness Joint Restraint: This system consists of a harness that is wrapped around the pipe and connected to a restraining gland. The harness provides both axial and radial restraint, keeping the pipe in place and preventing any movement. 5. Grip-Lock Joint Restraint: This system utilizes a wedge-shaped restraint that is inserted into the pipe's bell. The wedge expands and locks into place, providing both axial and radial restraint. 6. Restrained Joint System: This system incorporates a combination of mechanical and flexible joint restraints. It typically includes a mechanical joint adapter, a flexible joint restraint, and a restraining gland, providing both axial and radial restraint. These joint restraint systems are designed to meet specific application requirements and are often specified by engineers based on factors such as pipe diameter, operating pressure, and soil conditions. Each system has its own advantages and limitations, and the selection depends on the specific project needs and constraints.

- Q: What is the expected hydraulic efficiency of ductile iron pipes?

- The expected hydraulic efficiency of ductile iron pipes is generally high, as they have a smooth interior surface that minimizes friction and allows for efficient flow of water or other fluids.

- Q: How do ductile iron pipes handle ground settlement near construction sites?

- Ductile iron pipes are highly resilient and can withstand ground settlement near construction sites. Due to their flexible nature, these pipes can accommodate small movements and settlement without incurring significant damage or failure. The ductility of the material allows the pipes to bend and adjust to the changing ground conditions, ensuring their integrity and minimizing the risk of leaks or breakage. Additionally, the strong and durable properties of ductile iron make it a reliable choice for underground infrastructure, providing long-term stability even in challenging environments.

- Q: Can ductile iron pipes be used for underground sewage systems?

- Yes, ductile iron pipes can be used for underground sewage systems. Ductile iron is a type of cast iron that has enhanced flexibility and strength, making it suitable for various applications, including sewage systems. Ductile iron pipes offer several advantages for underground sewage systems. Firstly, they have excellent corrosion resistance, which is crucial in sewage systems where the presence of moisture and chemicals can cause corrosion over time. This resistance to corrosion ensures the long-term durability and reliability of the pipes. Secondly, ductile iron pipes have high tensile strength, allowing them to withstand the pressure and stress that can occur in underground sewage systems. They are resistant to ground movements, such as soil settling or shifting, which can cause damage to other types of pipes. Furthermore, ductile iron pipes have a smooth internal surface, which results in a better flow capacity and reduces the likelihood of clogging or blockages in the sewage system. This smooth surface also helps to minimize the accumulation of debris and sediment, reducing the need for frequent maintenance and cleaning. Another important factor is that ductile iron pipes are available in various sizes and can easily be connected using a range of joint systems, allowing for flexibility in designing and constructing underground sewage systems. In summary, ductile iron pipes are an excellent choice for underground sewage systems due to their corrosion resistance, high tensile strength, smooth internal surface, and ease of installation.

- Q: How many meters does the cast iron water supply pipe dn150,1 tons?

- Reciprocating centrifuge hydraulic device, the pressure was 9.65 x 105Pa. the speed through the overflow valve, cable and cooling water hose is generally fixed on the centrifuge and the machine next to the post, the other end is connected to the shell, random moving together. The production standard of centrifuges is usually fixed. If we want to produce several specifications of pipes on a centrifuge, we need to replace the fan-shaped packages, the hot metal flow plants and the support roller racks.

- Q: Can ductile iron pipe be used for marine and offshore applications?

- Yes, ductile iron pipe can be used for marine and offshore applications. Ductile iron is known for its high strength and durability, making it suitable for various demanding environments, including marine and offshore applications. It has excellent corrosion resistance, making it resistant to the corrosive effects of saltwater and other harsh conditions found in marine environments. Additionally, its ductility allows for flexibility and resistance to cracking or fracturing under high-pressure conditions. These properties make ductile iron pipe a reliable choice for transporting fluids and gases in marine and offshore industries, including offshore oil and gas platforms, marine structures, and underwater pipelines. It is important to note that proper coating and cathodic protection systems should be employed to further enhance the corrosion resistance of ductile iron pipes in marine and offshore applications.

Send your message to us

DI Pipes in Water project,ductile iron double flanged taper with concentric

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords