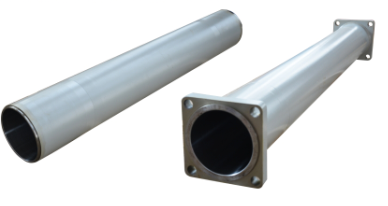

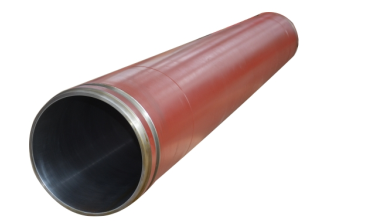

DELIVERY CYLINDER(SANY ) I.D.:DN200 CR. THICKNESS :0.25MM-0.3MM LENGTH:2162MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Packaging & Delivery

| Packaging Detail: | wooden case, seaworthy packing |

| Delivery Detail: | 15 days |

Specifications

Concrete Pump Delivery Cylinder DN230*2100

1. Capacity: 60,000~80,000cbm

2. Size: DN180, DN200, DN230..

4. Brand: PM, Sany,ZM

1. Material: C45

2. quenching and tempering to improve the hardness to HB241-280

3. inner wall chrome thickness is 0.25-0.30mm, hardness HV820-900.

4. Brand: SCHWING, PM, SANY, KYOKUTO, CIFA

5. Capacity: 60,000~80,000cbm

- Q: What are the most commonly replaced spare parts for concrete pumps?

- Concrete pumps commonly require the replacement of certain spare parts. These parts, including wear plates, wear rings, and delivery cylinders, are prone to constant abrasion and wear. This is a result of the high pressures and velocities involved in the movement of concrete. Wear plates, usually made from hardened steel, are installed in high-wear areas such as the hopper to protect against the abrasive nature of concrete. On the other hand, wear rings, made from durable materials like polyurethane, are utilized to minimize friction between the piston and cylinder, thereby reducing wear and maintaining optimal performance. Additionally, delivery cylinders, also known as pumping cylinders, play a crucial role in transferring concrete from the hopper to the discharge outlet. Over time, the interior surface of the cylinder may experience wear or damage, necessitating replacement to ensure efficient concrete flow. Other commonly replaced spare parts include pistons, seals, hydraulic hoses, and couplings. These components, too, undergo wear and tear during the pumping process. It is essential to regularly inspect and maintain these parts to prevent unexpected equipment downtime and ensure the long-term reliability and performance of concrete pumps.

- Q: How to operate the concrete pump?

- Start the position, adjust the handle, hand wheel, control lever, cock and so on. They should be in the correct position. The hydraulic system should be normal without leakage

- Q: What are the indications of a damaged concrete pump boom?

- There are several indications that can point to a damaged concrete pump boom. These indications can include: 1. Visual damage: One of the most obvious signs of a damaged concrete pump boom is visible physical damage. This can include cracks, dents, or deformities in the boom structure. Any signs of structural damage should be taken seriously as they can compromise the integrity of the boom. 2. Leaks: Another indication of a damaged boom is the presence of leaks. If you notice hydraulic fluid or water leaking from the boom, it could be a sign of a damaged hose or fitting. Leaks can not only affect the performance of the pump but also pose a safety risk to the operator and those working around the equipment. 3. Misalignment: A damaged boom may also exhibit misalignment issues. If the boom is not straight or appears to be bent at an odd angle, it could indicate damage. Misalignment can affect the accuracy and efficiency of concrete placement, potentially leading to uneven or improper pouring. 4. Unusual noises: Strange or excessive noises during operation can be a sign of a damaged boom. Rattling, grinding, or squealing sounds can indicate loose or worn-out components, such as pins, bushings, or bearings. These noises should not be ignored, as they could worsen if not addressed promptly. 5. Reduced performance: A damaged boom may also result in reduced performance. If you notice a decrease in pumping capacity or difficulties in controlling the boom's movement, it could be an indication of damage. Poor performance can be caused by various issues, including hydraulic system problems, structural damage, or worn-out parts. In conclusion, it is crucial to regularly inspect and maintain concrete pump booms to identify any indications of damage. Promptly addressing these issues is essential to ensure the safety of operators, prevent further damage, and maintain the efficiency and performance of the equipment.

- Q: What are the functions of concrete pump truck?

- It is composed of pump body and conveying pipe. It is divided into piston type, extrusion type and water pressure diaphragm type according to the structure. The pump body is mounted on the automobile chassis, and then equipped with telescopic or bent cloth rods to form a pump truck

- Q: How much do concrete pump spare parts typically cost?

- The cost of concrete pump spare parts can vary depending on several factors such as the brand, type of part, and the supplier. On average, concrete pump spare parts can range from a few hundred dollars to several thousand dollars. Common spare parts such as pistons, seals, and wear plates tend to have lower price points, while more complex components like hydraulic cylinders or control boards can be more expensive. Additionally, the quality and durability of the spare part can also affect the price. It is advisable to compare prices from different suppliers and consider factors like warranty and customer reviews before making a purchase.

- Q: What are the elements of concrete pump and concrete pump truck selection?

- The performance of the random type varies depending on the type and structure of concrete pump truck building, in addition to considering the choice of models into the concrete pouring amount, should also consider the building type and structure, technical requirements, construction site conditions and environment etc.. The main performance parameters of the concrete pump vehicle should be in line with the construction requirements or slightly larger. If the capacity is too large, the utilization rate is low, too small, not only can not meet the requirements, but also will accelerate the loss of the concrete pump truck.

- Q: How often should concrete pump water pumps be inspected and replaced?

- The frequency of inspection and replacement for concrete pump water pumps depends on several factors including the workload, operating conditions, and maintenance practices. Generally, it is recommended to inspect the water pump at least once a month to ensure its proper functioning. During the inspection, it is important to check for any leaks, unusual noises, or signs of wear and tear. If any issues are identified, immediate action should be taken to resolve them, such as repairing or replacing damaged parts. As for replacement, it is difficult to provide an exact timeframe as it varies depending on the quality of the pump, the intensity of use, and the level of maintenance. However, a general guideline is to consider replacing the water pump every 1-2 years for heavy usage or every 3-5 years for moderate usage. Regular maintenance, such as cleaning and lubricating the pump, can extend its lifespan and minimize the need for frequent replacements. It is important to note that these recommendations are general guidelines and may vary depending on the specific manufacturer's instructions, industry standards, and local regulations. It is advisable to consult the manufacturer's guidelines and seek professional advice from experts in the field to determine the appropriate inspection and replacement schedule for concrete pump water pumps in your specific circumstances.

- Q: How often should agitator shaft seals be replaced in a concrete pump?

- Agitator shaft seals in a concrete pump should typically be replaced every 6 to 12 months, depending on the usage and maintenance of the equipment. Regular inspection and monitoring of the seal's condition can help determine the appropriate replacement interval.

- Q: How can one ensure proper alignment and positioning of concrete pump spare parts during installation?

- To ensure proper alignment and positioning of concrete pump spare parts during installation, one should carefully follow the manufacturer's instructions and guidelines. It is essential to use the correct tools and equipment for the installation process. Additionally, thorough inspection and measurement of the parts before installation can help identify any discrepancies or misalignments. Proper torqueing of bolts and fasteners, as specified by the manufacturer, is also important to ensure secure and accurate positioning of the spare parts. Regular maintenance and inspection of the equipment can further help in identifying and rectifying any alignment issues.

- Q: How to choose concrete pump?

- The actual export pressure of concrete pump and the actual product per hour, the greater the value, the greater the capacity index, the power of the motor will be greater, thus achieving the purpose of large displacement, high lift

Send your message to us

DELIVERY CYLINDER(SANY ) I.D.:DN200 CR. THICKNESS :0.25MM-0.3MM LENGTH:2162MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords