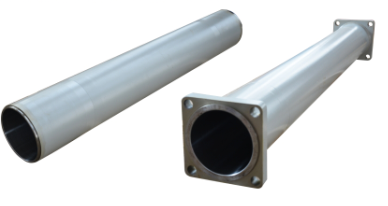

DELIVERY CYLINDER(SANY ) I.D.:DN200 CR. THICKNESS :0.25MM-0.3MM LENGTH:1946MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Packaging & Delivery

| Packaging Detail: | wooden case, seaworthy packing |

| Delivery Detail: | 15 days |

Specifications

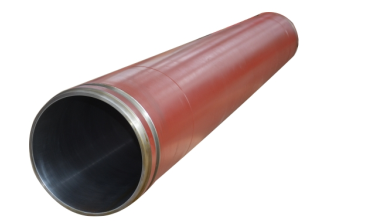

Concrete Pump Delivery Cylinder DN230*2100

1. Capacity: 60,000~80,000cbm

2. Size: DN180, DN200, DN230..

4. Brand: PM, Sany,ZM

1. Material: C45

2. quenching and tempering to improve the hardness to HB241-280

3. inner wall chrome thickness is 0.25-0.30mm, hardness HV820-900.

4. Brand: SCHWING, PM, SANY, KYOKUTO, CIFA

5. Capacity: 60,000~80,000cbm

- Q: Are there any specific guidelines for the installation of wear plates or wear rings in concrete pump spare parts?

- Concrete pump spare parts, such as wear plates or wear rings, have specific guidelines for their installation. These guidelines guarantee proper installation and optimal equipment performance. Here are some essential guidelines to consider: 1. Prior to installation, thoroughly examine the wear plates or wear rings for any damage or defects. Replace any damaged or worn-out parts to ensure efficient operation. 2. Ensure that the concrete pump and all related components are clean and clear of debris or contaminants. Doing so will prevent premature wear and prolong the lifespan of the wear plates or wear rings. 3. Before installation, apply a suitable lubricant to the wear plates or wear rings. This will minimize friction and extend the components' service life. 4. Proper alignment is crucial for the effective functioning of wear plates or wear rings. Make sure the plates or rings are correctly aligned and securely fixed in place. Misalignment can cause premature wear and equipment damage. 5. Use the recommended torque specifications to tighten the bolts or fasteners that secure the wear plates or wear rings. Improper tightening can result in equipment malfunction or damage. 6. Implement a regular maintenance schedule to inspect and replace worn-out wear plates or wear rings. Regular maintenance will help detect and address any issues before they lead to major breakdowns or costly repairs. It is important to consult the manufacturer's guidelines and adhere to their specific instructions for the installation of wear plates or wear rings in concrete pump spare parts. Following these guidelines will ensure the equipment's optimal performance and longevity.

- Q: How often should concrete pump accumulators be inspected and replaced?

- Concrete pump accumulators should be inspected on a regular basis to ensure their proper functioning and to prevent any potential issues. The frequency of inspections will depend on various factors such as the manufacturer's recommendations, the intensity of use, and the specific conditions in which the concrete pump is operating. As a general guideline, it is recommended to inspect concrete pump accumulators at least once every six months or after every 500 hours of operation, whichever comes first. However, if the pump is used more frequently or operates under harsh conditions, more frequent inspections may be necessary. During the inspection, the accumulators should be checked for any visible signs of wear or damage, such as leaks, cracks, or corrosion. Additionally, the pressure levels and performance of the accumulators should be tested to ensure they meet the required standards. When it comes to replacement, it is best to follow the manufacturer's recommendations. Typically, accumulators have a lifespan of around 3 to 5 years, but this can vary depending on factors such as maintenance, usage, and environmental conditions. If any significant issues are identified during the inspection or if the accumulators have reached their recommended lifespan, it is advisable to replace them promptly to avoid potential failures and ensure the safety and efficiency of the concrete pump.

- Q: How often should concrete pump control boxes be inspected and replaced?

- To maintain proper functioning and safety, it is essential to regularly inspect the control boxes of concrete pumps. The frequency of inspections and replacements will vary depending on factors such as pump usage, operating conditions, and manufacturer recommendations. In general, it is advisable to inspect the control box at least once a year or according to the manufacturer's guidelines. However, if the concrete pump is extensively used or exposed to harsh conditions, more frequent inspections may be needed. This involves checking electrical connections, switches, buttons, and indicators for signs of wear, damage, or malfunction. Moreover, inspections should be conducted after significant maintenance or repairs on the pump, as well as following any incidents or accidents. Regular inspections allow for early identification of potential issues, enabling timely repairs or replacements and reducing the risk of breakdowns or accidents. When it comes to replacements, control boxes should be replaced if they cannot be repaired or if they are outdated and no longer meet safety standards. It is important to consult the manufacturer or a qualified professional to determine the appropriate replacement schedule based on the specific conditions and usage of the concrete pump. Always remember, regular inspections and timely replacements of concrete pump control boxes are essential for ensuring the safe and efficient operation of the equipment.

- Q: What are the signs of a damaged concrete pump cylinder?

- Some signs of a damaged concrete pump cylinder can include reduced pumping performance, loss of pressure, leaks or drips around the cylinder, abnormal noises during operation, uneven wear or scoring on the cylinder wall, and visible cracks or deformations on the cylinder body.

- Q: How can a faulty concrete pump S valve affect the concrete flow?

- A faulty concrete pump S valve can affect the concrete flow by causing disruptions, blockages, or uneven distribution of the concrete. The S valve is responsible for controlling the direction of the concrete flow, and when it malfunctions, it can lead to decreased or inconsistent flow rates. This can result in delays in the construction process, poor concrete quality, or even damage to the pump system.

- Q: How to deal with the blockage in the outlet of the distributing valve of the concrete pump?

- If this method does not dare, it can only be manually removed, remove the connecting pipe, remove the debris in the valve.

- Q: How do I ensure the compatibility of mechanical components in concrete pump spare parts?

- To guarantee the compatibility of mechanical components in concrete pump spare parts, there are several essential measures you can take: 1. Determine the exact make and model of your concrete pump: Different concrete pumps may have different designs and specifications, so it is crucial to identify the specific make and model of your pump. This information will assist you in selecting the appropriate spare parts for your particular pump. 2. Review the manufacturer's documentation: Examine the manufacturer's documentation, which includes the user manual and parts catalog, to understand the recommended spare parts for your concrete pump. These documents typically provide detailed information on the compatibility of various mechanical components. 3. Seek guidance from the manufacturer or authorized dealers: If you have doubts about the compatibility of certain mechanical components, it is advisable to consult the manufacturer or authorized dealers. They possess extensive knowledge and experience with their products and can offer advice on choosing compatible spare parts. 4. Consider utilizing OEM (Original Equipment Manufacturer) parts: OEM parts are specifically designed and manufactured by the original equipment manufacturer. Employing OEM parts ensures the highest level of compatibility and reliability. Although they may be slightly more expensive than aftermarket alternatives, they often provide superior performance and longer service life. 5. Verify standardized sizing and specifications: Mechanical components, such as seals, gaskets, and bearings, frequently adhere to standardized sizes and specifications. Ensure that the spare parts you are considering match these standardized measurements to guarantee compatibility. 6. Conduct thorough research and comparison: Prior to purchasing spare parts, conduct research on various suppliers and compare their offerings. Look for reputable suppliers who specialize in concrete pump spare parts and have a proven track record of delivering high-quality, compatible components. 7. Perform compatibility testing: If you are unsure about the compatibility of a specific mechanical component, consider conducting compatibility tests. This may involve installing the spare part in your concrete pump and assessing its fit, function, and performance. If possible, seek assistance from a qualified mechanic or technician to assist you with these tests. By following these steps, you can ensure the compatibility of mechanical components in concrete pump spare parts, minimizing the risk of compatibility issues and ensuring the smooth operation and maintenance of your concrete pump.

- Q: Can I get spare parts for both single-cylinder and multi-cylinder concrete pumps?

- Yes, you can get spare parts for both single-cylinder and multi-cylinder concrete pumps. Many manufacturers and suppliers offer spare parts for different types of concrete pumps, including both single-cylinder and multi-cylinder models. These spare parts can include components such as hydraulic cylinders, pistons, seals, valves, hoses, and other essential parts that may need replacement due to wear and tear or damage. It is essential to reach out to the specific manufacturer or supplier of your concrete pump to inquire about the availability and compatibility of spare parts for your particular model.

- Q: What are the different types of concrete pump hoses?

- There are generally two types of concrete pump hoses: steel-reinforced hoses and fabric-reinforced hoses. Steel-reinforced hoses are stronger and more durable, suitable for high-pressure applications and long-distance pumping. Fabric-reinforced hoses are lightweight and flexible, ideal for smaller projects and shorter pumping distances.

- Q: What are the signs of a damaged or malfunctioning electric motor?

- Some signs of a damaged or malfunctioning electric motor may include unusual noises such as grinding or screeching, overheating, excessive vibration, sudden power loss or fluctuations, and a burning smell.

Send your message to us

DELIVERY CYLINDER(SANY ) I.D.:DN200 CR. THICKNESS :0.25MM-0.3MM LENGTH:1946MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords