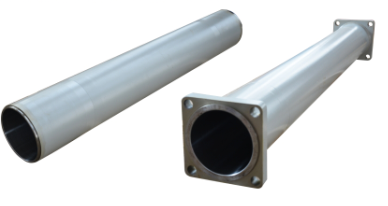

DELIVERY CYLINDER(SANY ) I.D.:DN180 CR. THICKNESS :0.25MM-0.3MM COLOR:WHITE LENGTH:1530MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Packaging & Delivery

| Packaging Detail: | wooden case, seaworthy packing |

| Delivery Detail: | 15 days |

Specifications

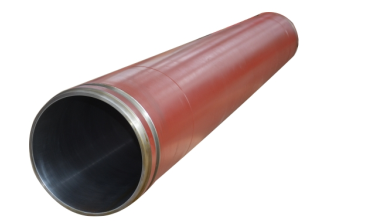

Concrete Pump Delivery Cylinder DN230*2100

1. Capacity: 60,000~80,000cbm

2. Size: DN180, DN200, DN230..

4. Brand: PM, Sany,ZM

1. Material: C45

2. quenching and tempering to improve the hardness to HB241-280

3. inner wall chrome thickness is 0.25-0.30mm, hardness HV820-900.

4. Brand: SCHWING, PM, SANY, KYOKUTO, CIFA

5. Capacity: 60,000~80,000cbm

- Q: What is the role of a concrete pump seal?

- The role of a concrete pump seal is to prevent leakage of concrete or other fluids from the pump system, ensuring that the pump operates efficiently and effectively.

- Q: Are there any specific guidelines for the installation of wear plates or cutting rings in concrete pump spare parts?

- Yes, there are specific guidelines for the installation of wear plates and cutting rings in concrete pump spare parts. These guidelines are important to ensure the proper functioning and longevity of the pump. 1. Firstly, it is important to clean the surface where the wear plate and cutting ring will be installed. Any debris, dust, or old material should be removed to ensure a smooth and secure fit. 2. The wear plate and cutting ring should be inspected for any damage or defects before installation. Any parts that are worn out or damaged should be replaced to avoid any potential issues during operation. 3. Apply a thin layer of lubricant or grease to the surface where the wear plate and cutting ring will be installed. This will help with the alignment and ease of installation. 4. Carefully align the wear plate and cutting ring with the designated slots or grooves in the concrete pump. It is crucial to ensure that they are accurately positioned to avoid misalignment or premature wear. 5. Use appropriate tools or equipment to secure the wear plate and cutting ring in place. This may involve tightening bolts, screws, or other fasteners. It is important to follow the manufacturer's instructions and torque specifications to ensure proper installation. 6. After installation, perform a visual inspection to ensure that the wear plate and cutting ring are securely in place and properly aligned. Any signs of misalignment or loose parts should be addressed immediately. 7. Regular maintenance and inspection of the wear plates and cutting rings are essential to identify any signs of wear or damage. It is recommended to follow the manufacturer's recommendations for maintenance intervals and replacement schedules. By following these specific guidelines, you can ensure the proper installation and function of wear plates and cutting rings in concrete pump spare parts, leading to improved performance and extended lifespan of the equipment.

- Q: Can concrete pump spare parts be used interchangeably between different pump brands or models?

- Using spare parts from different pump brands or models is not possible due to the specific specifications and dimensions of each pump. The spare parts must be manufactured to fit the requirements of the particular brand and model. Using spare parts from a different brand or model can lead to compatibility problems or even damage the pump. To ensure the pump functions properly and lasts a long time, it is always advisable to use genuine spare parts from the same brand or model.

- Q: How often should concrete pump gearboxes be inspected and maintained?

- Concrete pump gearboxes should be inspected and maintained at regular intervals, typically every 6 to 12 months. However, the frequency may vary depending on the specific operating conditions and usage of the concrete pump. It is important to follow the manufacturer's recommendations and guidelines for maintenance to ensure optimal performance and longevity of the gearboxes.

- Q: What are the common challenges in sourcing spare parts for stationary concrete pumps?

- Sourcing spare parts for stationary concrete pumps can pose several common challenges. Firstly, one of the major challenges is availability. Depending on the brand and model of the concrete pump, finding the exact spare parts needed may be difficult. Some manufacturers may not have a wide distribution network, which can make it challenging to locate the required spare parts in a timely manner. This issue can be exacerbated if the concrete pump is an older model or if the manufacturer has discontinued production. Secondly, cost is another significant challenge. Spare parts for stationary concrete pumps can be expensive, especially if they are sourced directly from the manufacturer. In addition to the initial cost, there may be additional expenses such as shipping, customs duties, and taxes, further increasing the overall cost of sourcing spare parts. Thirdly, quality assurance is crucial when sourcing spare parts. It is essential to ensure that the spare parts being sourced are of high quality and compatible with the specific make and model of the concrete pump. Poor-quality spare parts can lead to performance issues, breakdowns, and potentially safety hazards, which can be detrimental to the overall efficiency and longevity of the concrete pump. Furthermore, timing plays a vital role in sourcing spare parts. When a concrete pump breaks down, it can result in delays in construction projects, leading to additional costs and potential penalties. Therefore, finding spare parts quickly and efficiently is crucial to minimize downtime and ensure smooth operations. Lastly, language and communication barriers can also present challenges. If the manufacturer or supplier of the spare parts is located in a different country or speaks a different language, effective communication can be challenging. This can lead to misunderstandings, delays, and difficulties in accurately conveying the specific spare parts requirements. To overcome these challenges, it is advisable to work with reputable suppliers who specialize in concrete pump spare parts. These suppliers often have a wide range of spare parts in stock, ensuring availability and reducing the risk of delays. Additionally, establishing strong relationships with local distributors or authorized service centers can provide access to spare parts and technical support more efficiently. Regular maintenance and proactive planning can also help mitigate the challenges of sourcing spare parts for stationary concrete pumps. Keeping an inventory of essential spare parts and components can minimize downtime and ensure smooth operations.

- Q: What are the advantages of using polyurethane components in concrete pump spare parts?

- There are several advantages of using polyurethane components in concrete pump spare parts. Firstly, polyurethane is highly durable and resistant to wear and tear, ensuring longer lifespan and reduced maintenance costs. Secondly, polyurethane has excellent abrasion resistance, which allows it to withstand the harsh conditions and high pressures involved in concrete pumping. Additionally, polyurethane components offer superior flexibility, allowing for easier installation and reduced risk of breakage. Lastly, polyurethane is known for its chemical resistance, ensuring that the spare parts can withstand exposure to various chemicals and substances commonly found in concrete. Overall, using polyurethane components in concrete pump spare parts provides enhanced durability, flexibility, and resistance to abrasion, making it a preferred choice in the construction industry.

- Q: Which height of concrete pump is the most practical?

- Concrete pump truck height, according to their engineering height to determine, in reality the most widely used is 46 or 47 meters, this height is moderate, suitable for most projects in use

- Q: What are the advantages of using genuine spare parts for my concrete pump?

- Using genuine spare parts for your concrete pump comes with several advantages. First and foremost, genuine spare parts are specifically designed and manufactured by the original equipment manufacturer (OEM) for your concrete pump. This means that they are made to fit perfectly and function optimally with your specific model. Using genuine parts ensures compatibility and reduces the risk of compatibility issues or malfunctions that can arise from using aftermarket or counterfeit parts. Secondly, genuine spare parts are made from high-quality materials and undergo rigorous testing to meet strict quality standards. This ensures their durability, reliability, and performance, ultimately resulting in longer service life and reduced downtime for your concrete pump. Genuine parts are designed to withstand the demanding conditions and heavy loads that concrete pumps typically operate under. Moreover, using genuine spare parts helps maintain the warranty and integrity of your concrete pump. Many manufacturers offer warranties that cover the use of genuine parts. By using genuine parts, you can take advantage of the warranty benefits and avoid any potential issues that may arise from using non-genuine parts, which could void the warranty. Additionally, genuine spare parts often come with technical support and expertise from the manufacturer. OEMs have extensive knowledge and experience with their equipment, and their technical support team can provide guidance, advice, and troubleshooting assistance in case any issues arise. This can be extremely beneficial in minimizing downtime and maximizing the efficiency of your concrete pump. Lastly, using genuine spare parts ensures the safety of your equipment and operators. Genuine parts are manufactured to meet strict safety regulations and standards, reducing the risk of accidents or failures that can result from using substandard or counterfeit parts. The safety and well-being of your team should always be a top priority, and using genuine parts helps ensure their protection. In conclusion, the advantages of using genuine spare parts for your concrete pump include compatibility, quality, durability, warranty coverage, technical support, and safety. Investing in genuine parts not only enhances the performance and longevity of your equipment but also provides peace of mind for both you and your team.

- Q: Can concrete pump spare parts be ordered in bulk quantities for future use?

- Yes, concrete pump spare parts can be ordered in bulk quantities for future use. This can be beneficial to ensure a continuous supply of spare parts, reduce downtime, and potentially negotiate better pricing and discounts.

- Q: Can concrete pump spare parts be repaired on-site, or should they be sent to a specialized repair facility?

- Concrete pump spare parts can be repaired on-site in certain cases, while in others it may be necessary to send them to a specialized repair facility. The decision of whether to repair on-site or send for specialized repair depends on the nature and complexity of the repair required, the availability of skilled technicians and equipment, and the time constraints of the project. In many cases, minor repairs or replacements of simple components can be carried out on-site. These may include tasks such as replacing hoses, seals, or filters, which can be done quickly and easily with basic tools and equipment. These types of repairs can often be performed by the operators or maintenance personnel themselves, without the need for specialized technicians. However, for more complex repairs or replacements, it is advisable to send the spare parts to a specialized repair facility. This is particularly true for critical components such as hydraulic cylinders, valves, or control systems, which require specialized knowledge and expertise to repair properly. Specialized repair facilities have trained technicians who specialize in specific equipment and are equipped with the necessary tools and resources to diagnose and fix complex issues. Moreover, specialized repair facilities often have access to a wider range of spare parts and can source genuine parts from the original manufacturer. This ensures that the repaired spare parts are of high quality and compatible with the specific make and model of the concrete pump. Additionally, these facilities may offer warranties on their repairs, providing peace of mind to the equipment owners. Ultimately, the decision to repair on-site or send for specialized repair depends on the specific situation and resources available. It is important to assess the complexity of the repair, the availability of skilled technicians, and the potential impact on the project timeline before deciding on the most appropriate course of action.

Send your message to us

DELIVERY CYLINDER(SANY ) I.D.:DN180 CR. THICKNESS :0.25MM-0.3MM COLOR:WHITE LENGTH:1530MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords