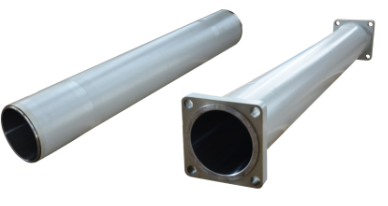

DELIVERY CYLINDER(PM ) I.D.:DN230 CR. THICKNESS :0.25MM-0.3MM LENGTH:1600MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Packaging & Delivery

| Packaging Detail: | wooden case, seaworthy packing |

| Delivery Detail: | 15 days |

Specifications

Concrete Pump Delivery Cylinder DN230*2100

1. Capacity: 60,000~80,000cbm

2. Size: DN180, DN200, DN230..

4. Brand: PM, Sany,ZM

Concrete Pump Delivery Cylinder DN230*2100

1. Material: C45

2. quenching and tempering to improve the hardness to HB241-280

3. inner wall chrome thickness is 0.25-0.30mm, hardness HV820-900.

4. Brand: SCHWING, PM, SANY, KYOKUTO, CIFA

5. Capacity: 60,000~80,000cbm

- Q: What are the potential risks of using non-standard or modified hydraulic components in concrete pump spare parts?

- Using non-standard or modified hydraulic components in concrete pump spare parts can pose several potential risks. Firstly, non-standard components may not have undergone the same rigorous testing and quality control as the original equipment manufacturer (OEM) parts. This means that their performance and durability may be compromised, leading to potential failures or malfunctions. Such failures can result in accidents, injuries, or damage to the equipment or surrounding structures. Secondly, using non-standard or modified components may void the warranty of the concrete pump and its spare parts. Manufacturers typically offer warranties to ensure the reliability and safety of their products. By using non-standard components, the warranty may become null and void, leaving the user responsible for any repairs or replacements needed due to issues arising from these non-standard parts. Another risk is the potential compatibility issues that may arise when using non-standard or modified components. Hydraulic systems rely on precise engineering and compatibility between various components to function optimally. Non-standard or modified parts may not fit properly or may have different specifications, leading to leaks, pressure imbalances, or reduced overall performance. Furthermore, the use of non-standard or modified components may also impact the overall efficiency and productivity of the concrete pump. OEM parts are designed to work seamlessly with the rest of the system, ensuring smooth operation and maximum output. By using non-standard parts, the performance of the pump may be compromised, resulting in increased downtime, decreased productivity, and higher maintenance costs. Lastly, the use of non-standard or modified components may also have legal and regulatory implications. In some jurisdictions, there may be regulations or standards in place that require the use of OEM or certified parts for certain equipment, including concrete pumps. Failure to comply with these regulations can result in fines, penalties, or legal liabilities in case of accidents or failures. In conclusion, the potential risks of using non-standard or modified hydraulic components in concrete pump spare parts include compromised performance and durability, warranty voidance, compatibility issues, reduced efficiency, and legal and regulatory implications. It is always advisable to use OEM or certified spare parts to ensure the safety, reliability, and optimal performance of the equipment.

- Q: How often should hopper grate clamps be inspected or replaced in a concrete pump?

- Hopper grate clamps in a concrete pump should be inspected regularly, preferably on a monthly basis, to ensure they are in proper working condition. However, the frequency of inspection may vary depending on the usage and operating conditions of the concrete pump. If the concrete pump is used extensively or subjected to harsh environments, more frequent inspections may be necessary, such as every two weeks or even weekly. On the other hand, if the pump is used less frequently or operates in less demanding conditions, inspections can be done less frequently, such as every two to three months. The purpose of these inspections is to identify any signs of wear, damage, or deterioration in the hopper grate clamps. Any loose or worn-out clamps should be promptly replaced to prevent accidents or disruptions during concrete pumping operations. It is crucial to prioritize safety and ensure that the hopper grate clamps are in good condition to secure the hopper grate effectively and prevent any unwanted material spillage. Regular inspections and timely replacements of hopper grate clamps will help maintain the efficiency and reliability of the concrete pump, ensuring uninterrupted operation and minimizing the risk of any potential issues.

- Q: How often should hopper agitator shaft seals be replaced in a concrete pump?

- The replacement frequency of hopper agitator shaft seals in a concrete pump relies on various factors such as pump type, usage amount, operating conditions, and maintenance practices implemented. In general, it is recommended to regularly inspect hopper agitator shaft seals for any signs of wear, damage, or leakage. If any problems are detected, they should be promptly addressed to prevent further harm. However, as a rough estimate, these seals may require replacement every 6 to 12 months or after approximately 500 to 1,000 operating hours. It is important to understand that this is merely an approximation, and the actual replacement frequency may differ. The quality of the seals, intensity of usage, and operating conditions of the pump can significantly impact the lifespan of the seals. Furthermore, regular maintenance and appropriate lubrication can aid in extending the durability of the seals. To ensure optimal performance and prevent potential issues, it is advisable to consult the manufacturer's recommendations and guidelines specific to the concrete pump model being utilized. Adhering to their guidelines and conducting regular inspections of the seals will aid in determining the appropriate replacement interval for the hopper agitator shaft seals and guarantee efficient pump operation.

- Q: How does a hydraulic oil cooler maintain optimal temperature in a concrete pump?

- A hydraulic oil cooler in a concrete pump helps maintain optimal temperature by dissipating heat generated during the hydraulic system operation. It typically consists of a heat exchanger that uses air or water to cool down the hydraulic oil. As the oil circulates through the cooler, the excess heat is transferred to the surrounding air or water, ensuring that the oil stays within the recommended temperature range. This prevents overheating and helps to maintain the efficiency and longevity of the hydraulic system in the concrete pump.

- Q: Are there any specific maintenance practices for concrete pump spare parts?

- Concrete pump spare parts should be regularly inspected for signs of wear or damage. This involves checking for visible defects like cracks, leaks, or any other issues. If any problems are found, the spare parts should be immediately replaced or repaired to prevent further damage. Regular cleaning is also essential for concrete pump spare parts. These parts often come into contact with cement, water, and other substances that can cause build-up and affect their performance. Cleaning them regularly will remove debris and residue, ensuring optimal functionality. Lubrication is another important maintenance practice for concrete pump spare parts. Properly lubricating moving components like bearings, seals, and pistons reduces friction and wear, extending the lifespan of the parts. It's crucial to use the correct lubricants recommended by the manufacturer and follow their application guidelines. Proper storage is also vital for maintaining spare parts. They should be stored in a clean, dry environment, away from chemicals or substances that could damage them. Additionally, spare parts should be protected from physical damage, such as being dropped or bumped. Lastly, it's recommended to adhere to the manufacturer's maintenance and replacement guidelines. Regular servicing and inspections by qualified technicians can help identify potential issues early on and prevent major breakdowns or failures. In summary, following specific maintenance practices like regular inspection, cleaning, lubrication, proper storage, and adherence to manufacturer's guidelines are crucial for ensuring optimal performance and longevity of concrete pump spare parts.

- Q: What are the indications of a weak or dead remote control battery?

- The signs of a weak or dead battery in a remote control can vary depending on the type of remote control used. Nevertheless, there are some common signs to look out for. One of these signs is a noticeable decrease in the operating range or distance of the remote control. This means that you may need to be closer to the device you want to control for the remote to work properly. Another sign is when the remote control buttons become unresponsive or require multiple presses to function. Additionally, you may observe a delay in the response time of the device when using the remote control. In certain cases, the remote control may stop functioning altogether, indicating that the battery is completely dead. If you notice any of these signs, it is advisable to replace the battery in the remote control to ensure reliable performance.

- Q: How often should concrete pump electric motors be inspected and maintained?

- Concrete pump electric motors should be inspected and maintained regularly to ensure their optimal performance and longevity. It is recommended to have them inspected at least once a year or every 500-1000 operating hours, whichever comes first. Additionally, regular maintenance should be carried out based on the manufacturer's guidelines and recommendations. This may include checking and replacing worn-out parts, lubricating moving components, cleaning dust and debris, and inspecting electrical connections for any signs of damage or loose connections. Adhering to a regular inspection and maintenance schedule will help prevent potential breakdowns, increase the lifespan of the motor, and ensure the concrete pump operates efficiently.

- Q: How does a concrete pump hopper grate prevent clogs?

- Preventing clogs in the concrete pump system is a crucial function of the hopper grate. Acting as a filter, it permits only the necessary aggregate size to pass through, while capturing any excess debris or large particles that could cause blockages. Strategically placed openings or grids in the grate catch these unwanted materials. When pouring the concrete mixture into the hopper, the grate serves as a barrier. It allows only the appropriate material size to pass through, while obstructing any larger or undesirable debris. This ensures a smooth flow of concrete through the pump system, preventing any disruptions or jams during construction. Furthermore, the grate is typically constructed from durable materials like steel or high-density polyethylene. These materials are resistant to damage and wear, allowing the grate to withstand the high-pressure environment and continuous operation without deformation. Regular maintenance and cleaning of the hopper grate are also essential to prevent clogs. By inspecting and removing any accumulated debris or build-up on a regular basis, operators can ensure that the grate remains clear and fully functional, thereby preventing potential clogging issues. In conclusion, the concrete pump hopper grate acts as a filter to prevent clogs, allowing only the necessary aggregate size to pass through while capturing larger particles and debris. Its design and durable material ensure a smooth flow of concrete, minimizing the risk of blockages and maintaining construction efficiency.

- Q: What is the purpose of a concrete pump piston?

- The purpose of a concrete pump piston is to pressurize and push the concrete mixture through a pipeline, enabling efficient and accurate placement of the concrete in construction projects.

- Q: Can concrete pump spare parts be imported from other countries?

- Yes, concrete pump spare parts can be imported from other countries.

Send your message to us

DELIVERY CYLINDER(PM ) I.D.:DN230 CR. THICKNESS :0.25MM-0.3MM LENGTH:1600MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords