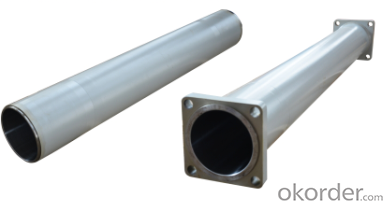

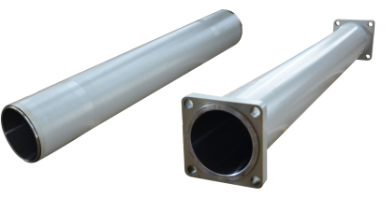

DELIVERY CYLINDER(PM ) I.D.:DN200 CR. THICKNESS :0.25MM-0.3MM COLOR:WHITE LENGTH:1585MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Packaging & Delivery

| Packaging Detail: | wooden case, seaworthy packing |

| Delivery Detail: | 15 days |

Specifications

Concrete Pump Delivery Cylinder DN230*2100

1. Capacity: 60,000~80,000cbm

2. Size: DN180, DN200, DN230..

4. Brand: PM, Sany,ZM

Concrete Pump Delivery Cylinder DN230*2100

1. Material: C45

2. quenching and tempering to improve the hardness to HB241-280

3. inner wall chrome thickness is 0.25-0.30mm, hardness HV820-900.

4. Brand: SCHWING, PM, SANY, KYOKUTO, CIFA

5. Capacity: 60,000~80,000cbm

- Q: What are the specifications for concrete delivery pumps?

- In the hot season construction, concrete pump to prevent the oil temperature is too high. When the temperature reaches 70 degrees, stop running or take other measures to cool down;

- Q: What is the purpose of a concrete pump hopper agitator motor?

- To ensure a smooth and consistent flow of concrete within the hopper, the concrete pump hopper agitator motor serves its purpose. It takes responsibility for mixing and agitating the concrete mixture, preventing any settling or thickening. By keeping the concrete in a fluid state, this motor ensures easy pumping and distribution through the delivery system. Absence of the agitator motor can result in the concrete mixture becoming stiff, causing blockages and delays in the pumping process. Ultimately, the concrete pump hopper agitator motor's aim is to maintain the quality and efficiency of concrete pumping operations by ensuring a well-mixed and smooth flow.

- Q: What are the indications of a malfunctioning concrete pump water pump?

- There are several indications that can point to a malfunctioning concrete pump water pump. 1. Lack of water flow: One of the most obvious signs of a malfunctioning water pump is a lack of water flow. If the water pump is not working properly, it may not be able to deliver water to the concrete pump, resulting in reduced or no water flow. 2. Reduced water pressure: Another indication of a malfunctioning water pump is reduced water pressure. If the pump is not functioning properly, it may not be able to generate enough pressure to deliver water effectively to the concrete pump. This can result in a weaker or inconsistent water stream. 3. Strange noises or vibrations: Unusual noises or vibrations coming from the water pump can be a sign of a malfunction. If there are any mechanical issues or loose components within the pump, it can cause these abnormal sounds or vibrations. 4. Overheating: A malfunctioning water pump may also overheat due to various reasons such as a clogged filter, worn-out bearings, or faulty motor. Overheating can lead to further damage and may eventually cause the pump to stop working altogether. 5. Leaks: If there are any visible leaks around the water pump, it is a clear indication of a malfunction. Leaks can occur due to damaged seals or gaskets, loose connections, or cracks in the pump housing. These leaks can lead to water loss and reduced pump efficiency. 6. Inconsistent or unpredictable water flow: When the water pump is not functioning properly, it may cause inconsistent or unpredictable water flow. This can result in irregular distribution of water to the concrete pump, affecting the quality and consistency of the concrete being pumped. It is important to regularly inspect and maintain the water pump to ensure its proper functioning. If any of these indications are noticed, it is recommended to immediately address the issue by contacting a professional to diagnose and repair the malfunctioning water pump.

- Q: What are the functions of concrete pump truck?

- It is composed of pump body and conveying pipe. It is divided into piston type, extrusion type and water pressure diaphragm type according to the structure. The pump body is mounted on the automobile chassis, and then equipped with telescopic or bent cloth rods to form a pump truck

- Q: How often should hydraulic filters be replaced in a concrete pump?

- Hydraulic filters in a concrete pump should be replaced regularly, typically every 500 to 1,000 operating hours or as recommended by the manufacturer. Regular replacement ensures optimal performance and helps prevent contamination and damage to the hydraulic system.

- Q: How often should hopper cylinder seals be replaced in a concrete pump?

- The replacement frequency of hopper cylinder seals in a concrete pump varies depending on factors such as seal quality, usage intensity, and maintenance practices. It is recommended to regularly inspect hopper cylinder seals for any signs of wear or damage, and if cracks, tears, or leaks are visible, immediate replacement is advised to prevent further damage to the concrete pump. In general, hopper cylinder seals can last for several months to a couple of years, depending on the aforementioned factors. However, it is crucial to establish a preventive maintenance plan and regularly monitor the seals' condition to ensure optimal performance and minimize downtime. Furthermore, consulting the manufacturer's guidelines or seeking advice from a professional concrete pump technician is advisable to determine the specific replacement interval for hopper cylinder seals based on the pump model, usage patterns, and environmental conditions.

- Q: What are the different types of concrete pump clamps?

- Concrete pump clamps come in various types, each serving a specific purpose and accommodating different pump sizes. Some commonly used clamps are as follows: 1. Snap clamps: These clamps utilize a snap mechanism, making them easy to install and remove. They are suitable for securing smaller diameter hoses and pipes. 2. Bolt clamps: Offering a stronger grip, bolt clamps consist of a metal band with bolts that can be tightened to hold the hose or pipe firmly in place. They are typically used for larger diameter hoses and pipes. 3. Wedge clamps: Wedge clamps use a wedge device to firmly secure the hose or pipe. They are commonly employed in high-pressure applications or when working with heavy-duty pumps. 4. Quick-release clamps: Designed for quick installation and removal, these clamps feature a lever or latch for easy adjustment. They are ideal for situations requiring frequent hose or pipe changes. 5. Flanged clamps: Specifically designed for pipes with flanges, these clamps establish a tight and secure connection between the pump and the pipe, preventing leaks or disconnections. To ensure the appropriate clamp selection, consider the specific requirements of your project, such as pump size, hose or pipe diameter, and expected pressure. Seeking guidance from a professional or supplier will assist you in choosing the suitable clamp for your needs.

- Q: How often should carbide wear plates be replaced in a concrete pump?

- The frequency at which carbide wear plates should be replaced in a concrete pump depends on several factors, including the type and quality of the plates, the intensity of usage, and the specific conditions in which the pump operates. Carbide wear plates are designed to endure heavy wear and tear caused by the abrasive nature of concrete. Generally, they have a longer lifespan compared to traditional steel wear plates. However, they are not completely immune to deterioration and will eventually wear down over time. A good rule of thumb is to regularly inspect the wear plates and monitor their condition. If the plates show signs of significant wear, such as visible cracks, excessive erosion, or reduced performance in terms of concrete flow, it is time to consider replacing them. In some cases, wear plates may need to be replaced annually, while in others, they may last several years. To prolong the lifespan of carbide wear plates, proper maintenance and care are essential. This includes regularly cleaning the plates, ensuring proper lubrication of the pump, and avoiding excessive pressure or abuse during operation. Regular maintenance can help to extend the lifespan of the wear plates and reduce the frequency of replacements. It is always recommended to consult the manufacturer's guidelines or seek advice from a professional concrete pump technician to determine the specific replacement interval for carbide wear plates in a particular pump model. They will have the expertise and knowledge to provide accurate recommendations based on the specific conditions and usage of the concrete pump.

- Q: How long do concrete pump hoses typically last?

- Concrete pump hoses typically last between 5 to 10 years, depending on various factors such as usage, maintenance, and the quality of the hose itself. Regular wear and tear, exposure to harsh chemicals, and extreme weather conditions can all contribute to the deterioration of the hose over time. Proper maintenance, including regular cleaning, inspection, and replacement of worn-out parts, can help extend the lifespan of the hose. However, it is important to note that regular monitoring and replacement of hoses are necessary to ensure the safety and efficiency of the concrete pumping process.

- Q: Are there any specific safety precautions for handling concrete pump spare parts?

- Yes, there are specific safety precautions that should be followed when handling concrete pump spare parts. Firstly, it is important to wear appropriate personal protective equipment (PPE) such as gloves, safety goggles, and a dust mask to protect against any potential hazards. Concrete dust can be harmful if inhaled or comes into contact with the skin, so it is important to take necessary precautions. When handling concrete pump spare parts, it is crucial to ensure proper lifting techniques are used to avoid strains or injuries. Heavy parts should be lifted with the help of lifting equipment or with the assistance of others to minimize the risk of accidents. Additionally, it is important to handle the spare parts with care and avoid any rough handling or dropping, as this can lead to damage or breakage. Damaged spare parts can affect the overall performance and safety of the concrete pump. Furthermore, it is recommended to store the spare parts in a clean and dry area, away from any moisture or chemicals that could potentially damage them. Proper storage will help maintain the quality and integrity of the spare parts. Lastly, it is always advised to follow the manufacturer's instructions and guidelines when handling concrete pump spare parts. They often provide specific safety precautions and recommendations that should be followed to ensure the safe handling and use of the parts. By following these safety precautions, the risk of accidents, injuries, and damage to the concrete pump spare parts can be minimized, ensuring a safe working environment.

Send your message to us

DELIVERY CYLINDER(PM ) I.D.:DN200 CR. THICKNESS :0.25MM-0.3MM COLOR:WHITE LENGTH:1585MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords