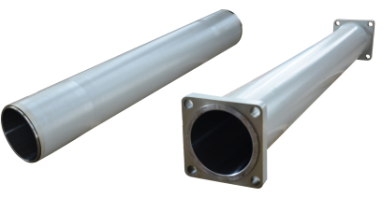

DELIVERY CYLINDER(PM ) I.D.:DN230 CR. THICKNESS :0.25MM-0.3MM LENGTH:2320MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Packaging & Delivery

| Packaging Detail: | wooden case, seaworthy packing |

| Delivery Detail: | 15 days |

Specifications

Concrete Pump Delivery Cylinder DN230*2100

1. Capacity: 60,000~80,000cbm

2. Size: DN180, DN200, DN230..

4. Brand: PM, Sany,ZM

Concrete Pump Delivery Cylinder DN230*2100

1. Material: C45

2. quenching and tempering to improve the hardness to HB241-280

3. inner wall chrome thickness is 0.25-0.30mm, hardness HV820-900.

4. Brand: SCHWING, PM, SANY, KYOKUTO, CIFA

5. Capacity: 60,000~80,000cbm

- Q: How can one identify the correct type of rubber seals or gaskets for concrete pump spare parts?

- To identify the correct type of rubber seals or gaskets for concrete pump spare parts, one should consider several factors. Firstly, it is important to know the specific model and make of the concrete pump to ensure compatibility. Additionally, one should evaluate the application requirements, such as the pressure and temperature conditions the seals or gaskets will be exposed to. Considering the material compatibility with the fluids or chemicals being pumped is also crucial. Consulting the manufacturer's specifications or seeking expert advice can provide further guidance in identifying the correct type of rubber seals or gaskets for concrete pump spare parts.

- Q: What are the signs of a malfunctioning lubrication system?

- Some signs of a malfunctioning lubrication system include increased friction and heat, unusual noises coming from the engine or components, excessive wear and tear on moving parts, and a decrease in overall performance and efficiency of the machinery or vehicle.

- Q: What is the purpose of a concrete pump carbide wear plate?

- A concrete pump carbide wear plate serves the purpose of facilitating the transfer of concrete from the hopper to the desired location by providing a resilient and long-lasting surface. Concrete pumps utilize a piston system to propel the concrete through the pump and into the delivery line. Throughout this process, the wear plate acts as a safeguard against the abrasive nature of the concrete. Concrete comprises various components such as sand, gravel, cement, and water. When forced through the pump, the concrete's abrasive particles can inflict substantial damage on the pump's internal elements, leading to reduced efficiency and increased maintenance expenses. The carbide wear plate is specifically engineered to endure the elevated pressures and abrasive forces encountered during the concrete pumping procedure. Constructed from a robust and durable material known as carbide, this wear plate supplies a resilient surface that minimizes wear and tear on the pump's internal parts. By incorporating a concrete pump carbide wear plate, contractors and construction experts can ensure the efficient and effective operation of their concrete pumps, with minimal interruptions for repairs. This not only saves time and money but also guarantees that the concrete is transported smoothly and consistently to the desired location, resulting in high-quality construction projects.

- Q: Are there any specific cleaning and maintenance procedures for concrete pump spare parts?

- Concrete pump spare parts require specific cleaning and maintenance procedures to ensure their proper functioning. Regular cleaning is crucial to remove any concrete buildup or residue from the parts. This can be achieved by either using a high-pressure water jet or immersing the parts in a cleaning solution specifically designed for concrete. It is vital to adhere to the manufacturer's instructions when using cleaning agents to guarantee the safety and effectiveness of the cleaning process. Furthermore, routine maintenance is necessary to extend the lifespan of the concrete pump spare parts and ensure their optimal performance. This involves inspecting the parts for any signs of wear, such as cracks or corrosion, and replacing them if needed. It is also important to lubricate the moving parts, like bearings or pistons, according to the manufacturer's recommendations. It is worth noting that different concrete pump spare parts may have unique cleaning and maintenance requirements. Therefore, it is advisable to consult the manufacturer's guidelines or seek guidance from a qualified technician to determine the appropriate procedures for each specific part.

- Q: What are the common signs of wear and tear on concrete pump spare parts?

- The common signs of wear and tear on concrete pump spare parts can vary depending on the specific part in question. However, there are some general signs that can indicate when a concrete pump spare part is experiencing wear and tear. One common sign is visible damage or deterioration on the surface of the part. This can include cracks, chips, or dents on the outer layer of the spare part. These damages can occur due to regular use, exposure to harsh environmental conditions, or accidental impact during operation. Another sign is increased vibration or noise during operation. If a concrete pump spare part is experiencing wear and tear, it may start to produce unusual vibrations or noises that were not present when it was in good condition. This can be an indicator of internal damage or misalignment of the part, which can affect its overall performance and efficiency. Reduced performance or efficiency is also a common sign of wear and tear on concrete pump spare parts. If a part is experiencing wear and tear, it may not function as effectively as before, resulting in decreased pumping capacity, reduced flow rate, or inefficient operation. This can lead to delays in construction projects and increased maintenance costs. Additionally, increased maintenance and repair requirements can indicate wear and tear on concrete pump spare parts. If a part needs to be repaired or replaced more frequently than usual, it could be a sign that it is experiencing wear and tear. Regular inspections and maintenance can help identify potential issues early on and prevent further damage to the spare parts. In conclusion, signs of wear and tear on concrete pump spare parts can include visible damage, increased vibration or noise during operation, reduced performance or efficiency, and increased maintenance requirements. It is important to regularly inspect and maintain these spare parts to ensure their optimal performance and prolong their lifespan.

- Q: What are the skills of concrete pump?

- In the process of pumping concrete, with the increase of pump pressure, pump impact force will force the tube to move back and forth, this is not only the loss of pumping pressure, and connecting parts between the pump in shock and intermittent tension state, can lead to premature damage, and rubber pipe cement slurry overflow, therefore must be fixed the pump

- Q: What is the purpose of a concrete pump remote control battery?

- The purpose of a concrete pump remote control battery is to provide power for the remote control device, allowing operators to remotely control the concrete pump's functions and movements without being physically connected to the machine.

- Q: Can concrete pump spare parts be purchased online?

- Indeed, online purchases of concrete pump spare parts are possible. Numerous online platforms and websites cater specifically to the sale of construction equipment and spare parts, including those for concrete pumps. These digital stores present a comprehensive assortment of options and brands, enabling customers to peruse and choose the precise spare parts required for their concrete pump. Moreover, online buying grants the convenience of price comparison, perusal of customer reviews, and doorstep delivery of the spare parts. Nevertheless, it remains imperative to ascertain the authenticity and dependability of the online store prior to making a purchase, guaranteeing the acquisition of genuine and top-notch spare parts.

- Q: How often should hydraulic cylinders be inspected or replaced in a concrete pump?

- Hydraulic cylinders in a concrete pump should be inspected regularly, ideally every 6 to 12 months, to ensure their proper functioning. Replacement of hydraulic cylinders should be done only when necessary, such as in cases of significant wear and tear, severe damage, or if they fail to meet safety standards.

- Q: What are the advantages of using ceramic components in concrete pump spare parts?

- There are several advantages of using ceramic components in concrete pump spare parts. Firstly, ceramic materials are known for their exceptional durability and wear resistance. Concrete pumps operate under high pressure and require components that can withstand the intense forces and abrasion. Ceramic parts have superior hardness and strength, making them highly resistant to wear and extending the lifespan of the spare parts. Secondly, ceramic components have excellent corrosion resistance. Concrete contains various chemicals and substances that can be corrosive to metals. By using ceramic parts, the risk of corrosion is significantly reduced, ensuring the longevity and reliability of the concrete pump spare parts. Additionally, ceramic materials have low friction coefficients. This means that when ceramic components are used in concrete pumps, there is less friction between the moving parts, resulting in reduced energy consumption and increased efficiency. This can lead to cost savings and improved overall performance of the concrete pump. Furthermore, ceramic parts have a high thermal resistance. Concrete pumps generate heat during operation, and this can cause damage or deformation to certain components. However, ceramic materials can withstand high temperatures without losing their structural integrity, ensuring the reliability and safety of the concrete pump. Lastly, ceramic components have excellent dimensional stability. They are less prone to expansion or contraction due to temperature changes, ensuring that the spare parts maintain their shape and fit accurately within the concrete pump. This precision fitting helps to minimize leakage and maintain the efficiency of the pump. In summary, the advantages of using ceramic components in concrete pump spare parts include exceptional durability, corrosion resistance, low friction, high thermal resistance, and dimensional stability. These benefits contribute to increased lifespan, improved performance, reduced maintenance costs, and enhanced overall efficiency of the concrete pump.

Send your message to us

DELIVERY CYLINDER(PM ) I.D.:DN230 CR. THICKNESS :0.25MM-0.3MM LENGTH:2320MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords