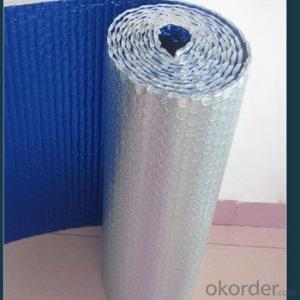

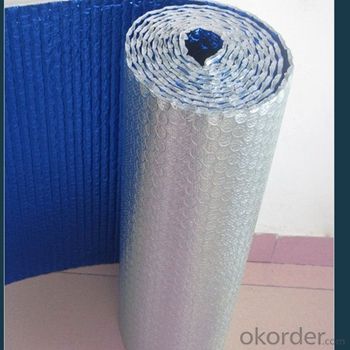

Decatur Al Residential Roofing Insulation - Aluminum Foil with LDPE for Bubble Foil Insulation Production

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 90 cm²

- Supply Capability:

- 33412 cm²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum foil facing insulation for Roofing Insulation

1. Aluminum Foil Facing Description:

The production technologies and products performance of aluminum foil facing have been up to international advanced level. The aluminum foil facing products are mainly used for HVAC system, refrigerators, building thermal aluminum foil facing insulation and laminated with glass wool and rock wool to increase the insulation function.

• FSK aluminum foil facing is mainly used for duct wrap in HVAC system and other fields, such as vapor barrier etc., and suitable for off-line lamination of glass wool or rock wool. By special processing, the facing will have excellent flame retardant property.

• Heat-sealing aluminum foil facing is used for duct wrap without applying extra adhesive and suitable for online lamination of glass wool and rock wool.

2.Main Features of the Aluminum foil facing:

• Light weight

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• High reflective insulation

• Heat resistant, water proof, stable at high temperature;

• environmentally friendly,no smell and not-toxic;

• Smooth and clear surface;

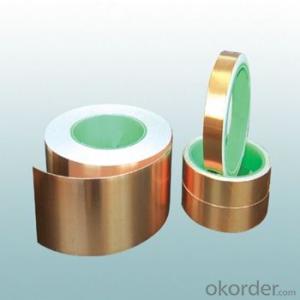

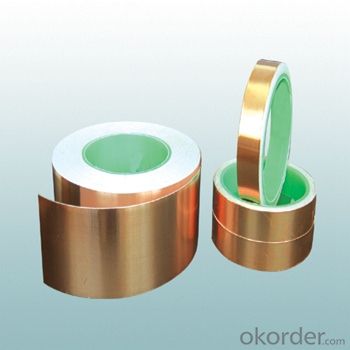

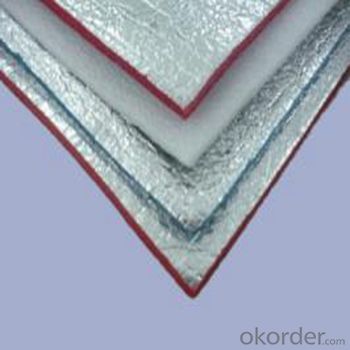

3.Aluminum Foil Facing Images

4.Aluminum Foil Facing Specification

TYPICAL PHYSICAL PROPERTIES:

Basic weight | gsm | 120 | ASTM D646 |

Tensile strength: M. D. X. D. | N/25mm | 140 75 | ASTM D828 |

Burst strength | N | 43 | ASTM D774 |

Reflectivity of foil surface | % | 95 | ---------- |

Temp. Resistance | -29°C 66°C | No Delamination No Delamination | ASTM C1263 |

Water vapor permeance | ng/N.s | 1.15 | ASTM E-96 |

Basic weight | gsm | 120 | ASTM D646 |

Tensile strength: M. D. X. D. | N/25mm | 140 75 | ASTM D828 |

Width: 1.0m, 1.2m, 1.25 m, 1.30, 1.37m

Length: 200m, 500m, 1000m, 2500m, 2750m, 3300m

Core I.D.: 3"(76mm ±1), 72mm ±1

Based on order, special sizes are also available.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

1. How about your company?

A world class manufacturer & supplier of aluminum foil facing and is one of the large-scale professional investment aluminum foil facing bases in China. Annually more than 1000 containers of aluminum foil facing are exported to markets in Europe, America and Japan.

What is the storage condition?

1,The products should be stored at room temperature and kept from wet and heat source.

2, It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

3, The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: I am really confused about this science stuff! Sustainability is terrible xP

- All versions of insulation are largely air that is kept from moving - air is a good insulator if convection - movement of heated or cooled air due to changes of density - is prevented. This assumes that a vapor barrier and caulking prevent actual air movement through the wall when a wind is blowing. Some insulators are also poor conductors of heat so the connection between inside and outside that might occur is broken. As it happens, glass used in fiberglass and minerals used in rock wool are actually pretty good conductors of heat in solid form but as fine particles and flakes they don't conduct well from one strand/piece to the next.

- Q: 1) What thickness of rigid insulation is used on flat roofs?

- 2" is what I always use.

- Q: this room has an aluminum roof and hardwood siding. All the heat hit the aluminum roof

- The best method is with a spray on expanding foam insulation. It will stick to the ceiling and has a very good R Factor (how the construction industry measures the insulation factor). Any other method will involve building an interior ceiling or penetrating the roof, which will cause water damage.

- Q: i am going to insulate my conservatory roof its poly carbon and dirt has got inside so cant clean what can i use its a semi flat roof i thought about using insulation board silver backed your comments will be gratefull

- I prefer the roofing inserts, but they dont offer as much insulation as the covering types, the best option if possible is to replace it with a good glass type roof though

- Q: In a house, it looks like an addition, that now is the kitchen , it feels HOT, it doesn't seem to have a very good insulation on the roof at all, the ceiling is already low, so, what can be done on the outside to give it more insulation?, i don't care what it is i just want to give it a GOOD insulation, the roof is flat and to shingles. Any IDEAS? , thanks!

- So there is no access above the ceiling, like a crawl space? If you cannot get above the ceiling to look then it will be difficult to determine, what you have or don't have up there. You may want to consult an insulation company for help. They may have ideas to blow in additional insulation. The spray foam that is on the link left by the other person is a foam sprayed on the roof decking and rafters when you have complete access to them. The person below me brings up another point, can you add any soffet vents to help with air flow?

- Q: roof was replaced eight years ago soon after there were leaks in the roof caused insulation toget wet then dry now the insulation is packed hard and has started to turn into power who would be responsible to replace the insulation.

- Only you. 8 years is long past any roofer's warranty

- Q: im thinking of putting rolled felt paper under my metal roofing would that work instead of the reflective insulation instead?

- Probably could, but it would look like crap. Painting the roof white would do a better job of keeping the metal cooler. I'd install a ceiling fan in the center of the roof instead to force the hot air out.

- Q: i like to put a layer of sand in roofing instead of insulation. it's fireproof and insulates better. plus it's free. how much weight can ceiling board handle? I find about 15 inches poured into the roof works fine so far. Saves me about $1600 each house built

- first sand is very heavy and will probably exceed the loading on the roof and walls the extra reinforcing you would need to make the house SAFE would far outway any savings

- Q: I have read in some articles about roofing that it is recommended to use attic roof insulation in ones roofing. Is this true?

- It's advisable to insulate the roof area attic to help keep the rooms below warm as heat escapes through the ceilings, but not so much if there is insulation in the attic! It's personal preference. Cheers

- Q: I am purchasing a mobile home with a shingled roof. The shingles need to be replaced (>15yrs old) and with the cost of heating going up each day I thought I would added some of that 2" thick rigid insulation. I would place this right on top of the existing roof and then place the firring strips for the metal roof right on top of the rigid insulation panels (which are 4x8'). By using 3" galvanized sheet rock screws I will get a good solid attachment. Then I will put the metal roofing on to the firring strips as normal. Does anyone see any downside to doing this? Has anyone tried this before?

- I agree with the soundness of every part of your plan EXCEPT not removing the original shingle roof. The shingle roof is already at the end of its usable life. There’s no benefit to covering up old problems, and they will most likely affect the durability of the new roof. Plus, removing the old roof gives you the opportunity to inspect and repair any issues with the roofing deck. Your new insulation and metal roof will attach better and perform better by removing the old shingle roof.

Send your message to us

Decatur Al Residential Roofing Insulation - Aluminum Foil with LDPE for Bubble Foil Insulation Production

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 90 cm²

- Supply Capability:

- 33412 cm²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords