Gaf Tapered Roofing Insulation Aluminum Foil with LDPE Heat Seal for Bubble Foil Facing Production

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 90 cm²

- Supply Capability:

- 33412 cm²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum foil facing insulation for Roofing Insulation

1. Aluminum Foil Facing Description:

The production technologies and products performance of aluminum foil facing have been up to international advanced level. The aluminum foil facing products are mainly used for HVAC system, refrigerators, building thermal aluminum foil facing insulation and laminated with glass wool and rock wool to increase the insulation function.

• Heat-sealing aluminum foil facing is used for duct wrap without applying extra adhesive and suitable for online lamination of glass wool and rock wool.

• The PSK aluminum foil facing, whose structure is white polypropylene/ fiberglass scrim/ kraft is mainly used for metal building insulation and suitable for the insulation of ware-house, factory, supermarket, office and so on.

• Double sided aluminum foil facing vapor barrier, whose structure is aluminum foil/ high strength kraft /fiberglass scrim /aluminum foil and laminated together by special flame retardant adhesive, can be used for roofing, wall insulation of house, warehouse, cold storages, factory and others.

2.Main Features of the Aluminum foil facing:

• Light weight

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• High reflective insulation

• Heat resistant, water proof, stable at high temperature;

• environmentally friendly,no smell and not-toxic;

• Smooth and clear surface;

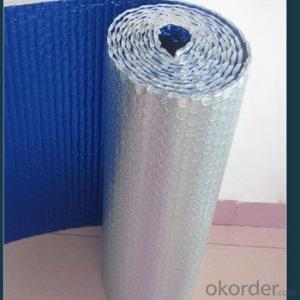

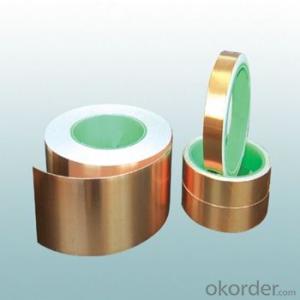

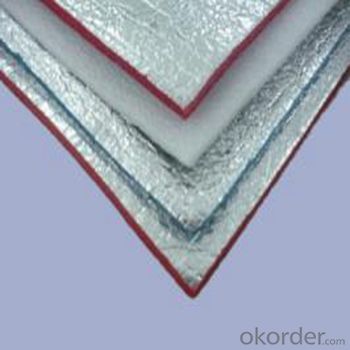

3.Aluminum Foil Facing Images

4.Aluminum Foil Facing Specification

TYPICAL PHYSICAL PROPERTIES:

Basic weight | gsm | 120 | ASTM D646 |

Tensile strength: M. D. X. D. | N/25mm | 140 75 | ASTM D828 |

Burst strength | N | 43 | ASTM D774 |

Reflectivity of foil surface | % | 95 | ---------- |

Temp. Resistance | -29°C 66°C | No Delamination No Delamination | ASTM C1263 |

Water vapor permeance | ng/N.s | 1.15 | ASTM E-96 |

Basic weight | gsm | 120 | ASTM D646 |

Tensile strength: M. D. X. D. | N/25mm | 140 75 | ASTM D828 |

Width: 1.0m, 1.2m, 1.25 m, 1.30, 1.37m

Length: 200m, 500m, 1000m, 2500m, 2750m, 3300m

Core I.D.: 3"(76mm ±1), 72mm ±1

Based on order, special sizes are also available.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

1. How about your company?

A world class manufacturer & supplier of aluminum foil facing and is one of the large-scale professional investment aluminum foil facing bases in China. Annually more than 1000 containers of aluminum foil facing are exported to markets in Europe, America and Japan.

What is the storage condition?

1,The products should be stored at room temperature and kept from wet and heat source.

2, It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

3, The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: Should a two story home have insulation under the roof in the big closets ?

- Any and all insulation helps wherever you put it! =)

- Q: My home is shaped like a square box. The four corners of the upper level have the roof pitch from the gables protruding into the rooms. The attic has no insulation and I need to insulate it. There is access from the attic to look down into the wall/ceiling that protrudes into the room. I can insulate the attic myself but the surface area of these protrusions is rather large. What would be the best way to get insulation down in there? Shoot the insulation in and poke it with a stick to make sure there is good coverage down in the wall space? The opening is about 6 inches high.Thanks.

- Loose fill cellulose can be blown into your attic. I don't know if I understand the protrusions that you are describing but if you can freely blow the cellulose fiber into this space it should serve as a good insulation. You don't want to poke it in with a stick because you don't want to compress it. If you cannot blow this product directly into the space, you would be better off stuffing it lightly with fiberglass batting. Just don't cram it too tightly. It needs to be loose to be most effective.

- Q: Why is the most insulation needed in ceilings or roofs? Just wanted to know

- well insulation in general is to keep the inside temperature different than the outside. since hot air usually rises, i think it is to keep warm air form escaping in winter. also you don't usually have a heater in the attic, or air conditioning so insulation will keep the air in the attic from having an effect on the air within the house. that is my idea as to why

- Q: should thermal insulation ever be applied directly to the underside of a roof top?

- yes its done all the time on metal buildings. works well but expensive.

- Q: what action should a plumber take?????

- struggling to understand your question! are you talking about a storage tank? what is the problem with the insulation? if it is in the way move it but insulation under a tank is not a problem the tank will need to be insulated any way!

- Q: Our end unit 1940"s row house has an old leaking bitumen roof . The water entry point can not be found so a replacement seems the way to go. A roofer suggested a replacement using Firestone 180, 1/2 inch fiberboard insulation covered with fiberglass base sheet, bitumen for flashing and fibered aluminum coating on wall coping . It's all Greek to be but fiberboard insulation and flashing material ? Should I be concerned?

- We use kingspan insulation, marine grade plyboard , 3/4 inch, and yes you can use bitumen as flashing. I hope i am not being condescending, but the flashing is the bit that goes from the roof and a little way up the wall and is then "pointed" into the bricks, thus forming a water-proof barrier.

- Q: Hi, I have got a physics question and was just wondering about it.. Can someone pls tell me how does roof insulation work? how is it effective? How does the insulation changes the heat circulation and transfer inside a house?I know that the insulation prevents radiation from the sun and overheating.. but any more details about radiation, convection and conduction of heat pls?

- Well insulation makes a dead air space (air is stagnant). Since the air is not moving the transfer of hot and cold is slowed down considerably. But since you have to create cross ventilation to reduce rotting in wood and the build up of explosive gasses. Its a crap shoot that it even does any good. Radiation is heat so that's covered by the dead air space. Convection is usually not an issue with the cross venting. Also for conduction the insulation should slow it down considerably.

- Q: i live in a tropical country and i need to insulate my roof to block off the heat from the sun...which insulation would best help me? aluminum foil with foam, real foil with foam or PE with foam? pls help...thank u so much!

- Expanded polystyrene (EPS) comes in sheets and is very long lasting and safe to use - no fibers, no itchy skin, no breathing issues....this is also used to keep cold out as well as heat and is durable.

- Q: hot because of all the added insulation. Is that what the insulation will do? Someone told me that it will save us on our cooling/heating bills, and that it will be warmer in the winter and cooler in the summer now. Is this true?

- Yes, you heard right. If you had no insulation, your air conditioner wouldn't be able to cool the house.

- Q: We have plenty down at the center, so many, you can carpet a garden. So, since I'll have to tear down the roof and improve the insulation in a few months, I was thinking of adding one extra layer... of emergency blankets. Since they can reflect the sun's heat up, and the heat under it down, will they do that for a whole house? Will the plastic film cause water condensation? If you wouldn't recommend it, then what would you recommend?

- They may help, but as thin as they are, installing them would be about as easy as putting socks on a rooster!

Send your message to us

Gaf Tapered Roofing Insulation Aluminum Foil with LDPE Heat Seal for Bubble Foil Facing Production

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 90 cm²

- Supply Capability:

- 33412 cm²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords