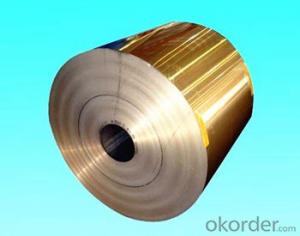

Radiator Aluminum Foil

Radiator Aluminum Foil Related Searches

Aluminum Foil Radiator Aluminum Foil On Radiator Radiation Aluminum Foil Aluminum Reflective Foil Capacitor Aluminum Foil Heat Resistant Aluminum Foil Roof Aluminum Foil Foil Aluminum Aluminum Thermal Foil Roll Aluminum Foil Aluminum Foil Coated Heating Aluminum Foil Aluminum Insulation Foil Round Aluminum Foil Royal Aluminum Foil Router Aluminum Foil Aluminum Laminated Foil Laminated Aluminum Foil Aluminum Foil Foam Solder Aluminum Foil Aluminum Foil Heater Decorative Aluminum Foil Rigid Aluminum Foil Al Aluminum Foil Aluminum Foil Wrap Cooking Aluminum Foil Rust Aluminum Foil Air Fryer Aluminum Foil Kitchen Aluminum Foil Reinforced Aluminum FoilRadiator Aluminum Foil Supplier & Manufacturer from China

Radiator Aluminum Foil is a type of specialized aluminum material designed for use in radiators and heat exchangers. It is engineered to provide efficient heat transfer and dissipation, ensuring optimal performance in various applications. This product is widely recognized for its durability, high thermal conductivity, and resistance to corrosion, making it a popular choice in the manufacturing of radiators and other heat management systems.Radiator Aluminum Foil is commonly used in automotive, industrial, and HVAC systems to enhance heat dissipation and maintain optimal operating temperatures. It is particularly useful in applications where space is limited, as its lightweight and flexible nature allows for easy installation and adaptation to various shapes and sizes. The product's ability to withstand high temperatures and resist corrosion makes it an ideal choice for environments with fluctuating temperatures and exposure to various chemicals or contaminants.

Okorder.com is a leading wholesale supplier of Radiator Aluminum Foil, boasting a large inventory to cater to the needs of various industries. As a reliable source for this product, Okorder.com offers competitive pricing and efficient delivery, ensuring that customers receive the high-quality Radiator Aluminum Foil they require for their projects. By partnering with Okorder.com, businesses can benefit from a steady supply of this essential material, enabling them to maintain their production processes and meet the demands of their customers.