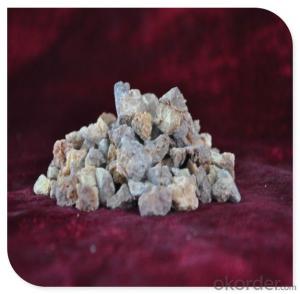

Raw Materials for Refractory:Dead Burnt Magnesite (MgO 88-92%) Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | China | Brand Name: | CNBM |

Packaging & Delivery

| Packaging Details: | as per buyer choice |

| Delivery Detail: | After LC confrmation 20 days. |

Specifications

Dead Burned Magnesite

Used for refractory materials.

MGO:86-90%min and 91-95%

Size;0-5mm,0-3mm,1-5mm and+

Dead Burnt Magnesite

Used for refractory Materials,

Mgo,----------- 88-90%min, and 90-95%

Sio2,----------- 4.5%max.

Cao,------------2.5% max.

Fe203,-------- 1.5% max.

Al,---------------1.5%max.

Loi,--------- ----1%max

B.D,-------------3.15%

Size; 0-2mm, 0-5mm and others

Paking; 50 Kgs , and than into 1000 Kgs bags or, as per buyer choice.

Payment; LC at sight, with 30% advance and 70% after BL.

Note: We can also produce Fluorspar 80% and white talc of 95% whiteness.

Basic Information

| Business Type: | Manufacturer, Trading Company | |

| Main Products: | Flourspar Lumps,Talc Lumps garephite,chrome ore copper ore,manganese ore Mica,DBM | |

| Number Of Employees: | 11 - 50 People |

Trade & Market

| Main Markets: | Western Europe Eastern Asia Mid East Southeast Asia Eastern Europe North America | |

| Total Annual Sales Volume: | Below US$1 Million | |

| Export Percentage: | 81% - 90% |

Factory Information

| Factory Size (Sq.meters): | 1,000-3,000 square meters | |

| Factory Location: | peshawar, NWFP, Pakistan | |

| No. of Production Lines: | 6 | |

| Number of R&D Staff: | 5 - 10 People | |

| Number of QC Staff: | 21 - 30 People | |

| Contract Manufacturing: | CNBM |

- Q: What are some of the new refractories and what are their characteristics?

- Refractory common AZS refractories are often used brick, corundum brick, magnesia chrome brick, silicon carbide, silicon nitride bonded silicon carbide, nitrides, silicides, sulfide, boride, carbide and other non oxide refractory materials; calcium oxide, chromium oxide, aluminum oxide, beryllium oxide and other refractory materials, Magnesium Oxide

- Q: What's the texture of refractory for the hearth of reverberatory?furnace? ?

- The long-term usage temperature of ceramic fiber is between 950-1260 degrees.

- Q: How to divide fire rating of decorating materials ?

- Decorating materials shall be divided into four levels according to combustibility. Level A: noninflammability; B1: difficult-flammability; B2: combustibility; B3: inflammability.

- Q: Which refractory quality inspection authority is good?

- National testing agencies include National Refractory Inspection Center (i.e. LIRR), China Building Materials Academy (Guanzhuang, Beijing), National Center for Ceramic and Refractory Materials Inspection (Shandong) and China Metallurgical Research Institute (Beijing).

- Q: Who knows what kind of fire prevention materials are there?

- 1, Fire-proof board Fire-proof board is the most frequently used materials in the market. There are two kinds of fireproof boards which are commonly used; one is the high pressure decorative board, which has the advantages of fire prevention, damp proof, abrasion resistance, oil resistance, easy cleaning, and more variety of colors and designs. The other one is a glass magnesium fire board, the outer layer of which is a decorative material, the inner layer of which is a mineral glass magnesium fire material. It can resist 1500-degrees high temperature, but not suit for decoration. The installation of fireproof ceiling in the exit passageway, stair well and corridor can ensure safety evacuation, and protect people from the spread of the fire. 2 Fire-proof door Fireproof door is divided into wooden fire proof door, steel fire proof door and stainless steel fire proof door. Usually the fire proof door is used for the opening of the firewall, the entrance to the staircase, the evacuation of the aisle, the openings of the pipeline and other parts of the building, and it has an important role in fire separation and reducing the loss from fire. 2 Fire resisting shutter I hope it may be helpful to you.

- Q: What are the types of refractory sealant?

- 1. The characters of sealant for construction According to the characters, sealant for buildings are classified into caulk, sealants and construction sealant in China; They are named in accordance with the function and different basepolymeters. In the relevant standard for products,

- Q: Who knows the fire endurance of B-level fireproof doors and windows?

- B-grade fireproof windows refer to those fireproof windows whose fire retardant limit is not less than 1 hour. Technical requirements: I. Materials and Accessories (1) Window frame should have a certain strength to ensure the integrity and stability of the steel frame or the wood frame. (2) Steel frame and mound layer can employ galvanized?steel?sheet or stainless steel plate. Its selection criteria should be in line with the stipulation of the Article 5.1 of GB12955 "General Technical Requirements of Steel Fireproof Doors". (3) The selection standard of wood frame and mound layer should be in line with the provision of Article 5.1.1 of GB14101 "General Technical Requirements of Wooden Fireproof Doors". (4) Filling materials inside steel frame and wood frame should be non-combustible materials.

- Q: Could you tell me the fire-resisting time of class B fire proof door?

- The fire-resisting time of class B fire proof door is 1h and thickness of door can't be lower than 45mm.

- Q: Who knows how many poured refactory material are there?

- Casting refractory material, refractory material used often are AZS brick, corundum brick, direct bonding magnesia chrome brick, silicon carbide, silicon nitride bonded silicon carbide brick, nitrides, silicides, sulfide, boride, carbide and other non oxide refractory materials; calcium oxide, chromium oxide, aluminum oxide, magnesium oxide, beryllium oxide and other refractory materials.

- Q: How to divide the fire resistant level of construction thermal insulation materials?

- 1, Combustion performance of the national standard building materials are divided into the following levels: Class A: incombustible building material: Material that almost never burn. Class B1: nonflammable building material: Nonflammable materials have good effect of flame resistance. In case of fire it in the air or at high temperature it is difficult to catch fire and spread, and when the fire source is removed, the combustion can stop immediately. Class B2: combustible?building?material: Combustible materials have good effect of flame resistance. In case of open fire in the air or at high temperature, it will immediately burst into flames and spread the fire quickly, such as wooden column, timber roof truss, wooden stairs, etc. Class B3: flammable building material: No flame-retardant effect, highly flammable, high risk of fire. 2, According to fire?rating, external wall thermal insulation materials can be divided into 1) thermal insulation material with class A combustion performance. Rock wool, glass wool, foam glass, foamed ceramics, foam cement, hole-closed perlite,etc. 2) thermal insulation material with class B1 combustion performance: Extruded polystyrene board (XPS) after special treatment /polyurethane (PU) after special treatment , phenolic aldehyde, gelatine powder polyphenyl granule, etc. 3) thermal insulation material with class B2 combustion performance: Molding polystyrene board (EPS), extruded polystyrene board (XPS), polyurethane (PU), polyethylene (PE), etc.

Send your message to us

Raw Materials for Refractory:Dead Burnt Magnesite (MgO 88-92%) Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords