Cylindrical Roller Bearing , Chinese Factory NUP 306 E High Precision

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 100000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Specifications:

Cylindrical roller and race for line contact bearing. Load capacity is big, mainly bear radial load .

1. Friction coefficient is small, suitable for high speed limit speed close to deep groove ball bearings

2.N and NU type axial movement, can adapt to shaft caused by thermal expansion or installation error and shell the change of relative position, can be used for free end bearing

3. On the shaft or hole of the processing and the demand is higher, bearing outer axis relative deflection after installation to be kept under strict control, so as not to cause contactstress concentration

4. Inner ring or outer ring separable, easy to install and remove

Specification | Model No.: NUP 306 E |

Brand Name: OEM | |

Size:30*72*19mm | |

Net weight: 0.370kg | |

Material: Chrome steel | |

Cage: Brass, Steel | |

Features: | 1) Precision: P6 P5 P4 P2 |

2) Noise level: Z1, Z2, Z3, Z4 | |

3) Vibration Level: V1, V2, V3, V4 | |

4) Clearance: C2, C3, C4 | |

5) Hardness: 58-63 HRC | |

6) Greese: As your requirement, such as SRL, PS2, Alvania R12 and so on. | |

Packing | 1.Industrial packing: box |

2.Commercial packing: box then into standard carton/wooden Box | |

3.According customer's requirement | |

Payment | T/T, L/C, Western Union |

Delivery time | About 3 to 5 working days |

Services | Warrantee: 1 year |

Samples: available | |

OEM: available | |

Free technical support and after-sales service |

Packaging & Delivery

Packaging Details: | plastics wrapping bearings - wrapping papers - polywoven bag - carton for outside package - wooden box /According to your order |

Delivery Detail: | 30-40days/according to your order |

Product Applications:

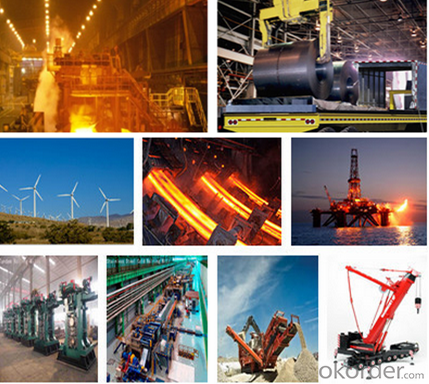

Cylindrical Roller Bearing Application Flied:Rolling Mills,Crusher,Mining

Metallurgy Petroleum,Chemical Industry,Engineering Machinery,Port,Oil,Gas,

Wind,Agriculture,Lathe,CNC,Steel Works,Electrical Machinery,Axle/Limber,

Tractor,Autocar,Crude Oil Engine and so on.

Our Advantages:

1. Excellent and high quality control

2. Prompt delivery

3. Competitive price

4. Small order accepted

5. Customers' drawing or samples accepted

6. OEM service

FAQ:

WHY CHOOSE US ???

1.More than 28 years export experience

2.Strict quality control

3.Delivery in time

4.OEM service are available with good price

5.Low MOQ

- Q: NSK cylindrical roller bearings EW/EM series of differences and characteristics

- E international is called "reinforced type" load, also means to increase rolling bodyW international is called a steel cage

- Q: Can the Nu and N type NJ NUP cylindrical roller bearings bear axial force?

- The answer upstairs is clear. Such bearings can not be designed with axial force. In use, the inner and outer rings of the bearing can have larger axial displacement, and the aim is to compensate the length change caused by the rotating part of the two bearing due to the temperature rise.

- Q: In the car there is a cylindrical roller, the size of the diameter of 25mm, the outer diameter of 32mm, width of 9.5mm, who knows what the standard size, have direct purchase Mody, thank you!

- Bearing (Bearing) is an important component of modern mechanical equipment. Its main function is to support the mechanical rotating body, reduce the friction coefficient during its movement and guarantee its rotation accuracy.According to the friction property of the moving element, the bearings can be divided into two kinds: rolling bearing and sliding bearing. Among them, the rolling bearing has been standardized and serialized, but compared with the sliding bearing, its radial dimensions, vibration and noise are relatively large, and the price is higher.Generally, the rolling bearings are composed of four parts: the outer ring, the inner race, the rolling body and the cage. According to the shape of the rolling element, the rolling bearings are divided into two major categories: ball bearings and roller bearings.

- Q: Attention problems of cylindrical roller bearings

- 1. The installation of bearings must be carried out in a dry, clean environment. Before installation, the machined surface of the shaft and shell, the shoulder end, the groove and the joint surface shall be carefully inspected. All mating surfaces must be carefully cleaned and removed, and the cast surface must be clean. 2, before the installation of bearings, should be cleaned with gasoline or kerosene, dry after use, and ensure good lubrication, bearings generally grease lubrication, oil lubrication can also be used. Grease lubrication, grease, anti rust, extreme pressure and other excellent greases should be used. Grease filling capacity for bearings and bearing box volume of 30%-60%, should not be too much. Double row tapered roller bearing and water pump shaft bearing with sealing structure have been filled with grease, which can be used directly by users and can not be cleaned again. 3, bearing installation, must be applied equally in the circumference of ferrule end face pressure to press into the ring, and may not directly tap bearing end face to the top tool, so as not to damage the bearing. Small amount of interference in the case, at room temperature can be used to suppress sleeve bearing ring face, beating with a hammer sleeve, the sleeve will be pressed into the ring balance. If installed in large quantities, use hydraulic press. When pressing, the outer end surface of the outer ring and the outer shoulder of the shell face shall be ensured, and the inner ring end face is tightly pressed with the shoulder end of the shaft platform, and no gap is allowed.

- Q: Can cylindrical roller bearings bear high temperature?

- A class of grease, temperature is not more than 120 degrees, and then high temperature will lose lubrication performance, leading to the bearings can not work, in fact, bearing itself can withstand high temperature.

- Q: Is the roller bearing and the bearing chamber movable in the tapered rotor motor?

- E in cylindrical roller bearing is the meaning of improving internal cage design, similar to the SKF cylindrical roller bearing EC form, this type of bearing than without E, is to strengthen the design, the roller is filled more larger to increase the load. From the load point of view, it is better to choose E.

- Q: What's the difference between imported bearings and imported bearings?

- Domestic bearings used in the cage and rivet and washer, spacer ring, sealing ring, pillar, pin etc. the material is divided into black metal materials (such as low carbon steel, stainless steel etc.), non-ferrous metal materials (such as brass, bronze and Aluminum Alloy etc.) and non metal materials (such as plastics, phenolic textolite three) etc..

- Q: What are the components of cylindrical roller bearings?

- The utility model has the advantages of convenient installation and disassembly, especially when the inner, outer ring and the shaft and the shell are in interference fit. Such bearings are generally only used to bear radial load, only the inner and outer ring with single block bearings can bear less axial load or larger intermittent axial load.

- Q: Can it be used for axial alignment? Forty-fiveWhat is the function of the flat retaining ring of NUP cylindrical roller bearings with flat retaining rings? Can it be used for axial alignment?How much axial force can I bear then?You are the ZWZ? Can you make a friend?!How much axial force can you bear? Do you have a formula or a recommended value?NUP is needle roller bearings, brothers, I dialed the wrong number:What is the function of the flat retaining ring of the needle roller bearing with flat ring NUP? Can it be used for axial alignment?There seems to be no experts here, all mixed up

- Yes, the function of the flat ring is to bear the axial force and be used for axial positioning.

- Q: Why should the main shaft be coupled with double row cylindrical roller bearings?

- Because double row cylindrical roller bearings with high carrying capacity, high precision, separation, easy installation and disassembly, mainly used in lathes, milling machines, machining centers and other high-precision machine tool spindle. Hope to be of help to you.

Send your message to us

Cylindrical Roller Bearing , Chinese Factory NUP 306 E High Precision

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 100000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords