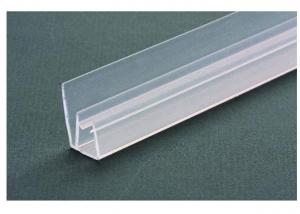

Custom Molded EPDM

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Pieces pc

- Supply Capability:

- 2000 Pieces per Day pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description of Custom Molded EPDM

ISO9001 & TS16949 factory

different size/ color is available

OEM service

custom molded EPDM/silicone rubber damper mount with in house mold SO9001 & TS16949 factory

WSR's mold workshop Description:

1. WSR have 12 CNC machines, 3EDM machines, we can make over 100sets rubber mould per month.

2. Compression/transfer/injection(both hot runner and cold runner are available) types.

3. The common mold steel we use are NAK80, P20, 4140, S50C

4. We have 15years experience in making rubber moulds, especially for rubber molds of electronic rubber parts, automotive rubber parts, toy tires, we are a leading rubber mould maker in China.

5. We have our own rubber products workshop, we can test the mold before ship the mold to customer.

6. We are currently making molds for Japan, Italy, UK, USA, Canada, South Asia companies.

7. Experience sales representative discuss with customer about the mold design prior to mold making.

8. Lead-time, prototype mold in 3-7days, production mold in 1-2weeks, complicated rubber molds like cold runner injection rubber molds in 30days.

Description of Custom Molded EPDM

Material: comply to RoHS, silicone or rubber (NR, SBR, NBR, EPDM, CSM, CR, HNBR, VITON, AFLAS and more)

Hardness: 8 to 95 shore A, tolerance can be ±5 shore A, for some special products, we can reach ±3 shore A tolerance

Color: for rubber, usually black, for silicone, can be in any color as you want

Machine type: 50 to 400 tons

Molding service: we have our own mold workshop which have 12 sets CNC machines and provide compression/transfer/injection rubber molds

ISO9000 and TS16949 certificated factory

Mold/samples lead-time of Custom Molded EPDM

For prototype mold, usually in 7days

For mass production mold, usually in 2 weeks

For some special molds, can be in 30days, especially for some automotive rubber molds

Small orders are welcomed

- Q: What are the properties of rubber used in automobile tyres?

- Rubber car tires, mainly on the properties of rubber itself, elastic body, modulus of elasticity and modulus of rigidity suitable for shock absorption!

- Q: There is a smell of rubber and plastic in the inner room. What's wrong with it?

- If the clutch is used, the policy is not obvious, the gear is not smooth or difficult to start. When you get off the car and smell the smell coming from the rear of the car, you should check whether the brake system is overheated. Some owners forgot to put the handbrake on, so after the brakes locking, will also have a burning smell.

- Q: Installation method of automobile door glass sealing strip

- Installation should be inserted in place, the surface flat, close contact with glass, glass notch, so that the surrounding glass force evenly. At the corner, the rubber strip should be beveled to open and glue firmly at the break. When sealing the glass with sealant, the rubber or rubber block shall be used to squeeze the glass into space, the glue filling depth shall be no less than 5mm, and the glass shall be free from vibration before the glue solidifies.

- Q: How to determine the service life of car tires? A new pair of tires is how to use the length of time or number of kilometers to judge?

- There will be a wear mark on the tire. Wear to this mark shows that the tread depth of the tire has been less than 1.6MM, you need to change the tire.

- Q: What's the use of the rubber in the middle of the front axle?

- Play the role of counterweight, to ensure high speed when the body is not shaking, and balance stability

- Q: Does the cushion cushion affect the vehicle?

- Its working principle is: it is installed on the spiral rubber shock absorber spring, when the car turns to shift the focus to the side causing the body tilt to the compression spring played a supporting role, so it can reduce the car roll. Is not to withstand the shock absorber spring over compression, it is not normal straight work but will make the spring more tough.

- Q: What are the advantages and disadvantages of automobile shock absorber installation?

- Shock absorption rubber pad is a kind of rubber embedded in the damping coil spring of the automobile. The cushion can act as a shock absorber, but its biggest function is noise insulation.

- Q: How much is the Elantra car wiper size?

- The wiper is often used, and rubber which is easy to wear, so we should often check, lift the wiper, fingers after cleaning the rubber wiper blade on the touch, if rubber aging, hardening and crack, then it should replace the wiper rubber strip the. If the vehicle is exposed for long periods of time, the wiper should be lifted and a soft object underneath. Or stand up, too, so that rubber strips can be over aged. In rainy days, when the subject, should put the wiper up, avoid frozen frozen wiper.

- Q: What's the tire composition?

- A tire is a ring shaped elastic rubber product that is grounded and mounted on various vehicles or machinery. The utility model is usually arranged on the metal rim, can support the vehicle body, buffer the external impact, realize the contact with the road surface, and guarantee the driving performance of the vehicle.

- Q: How to change the rubber strip for boneless wiper?

- After the clip down we can see the rubber strip is going to change is through a metal buckle fixed on the wiper above, then we just like to clip the metal buckle pry up, can remove the rubber strip.

1. Manufacturer Overview

| Location | Guangdong,China (Mainland) |

| Year Established | 2007 |

| Annual Output Value | |

| Main Markets | Domestic Market Rubber and Plastic Products 61.8 Northern Europe Rubber and Plastic Products 2.7 North America Rubber and Plastic Products 10 Oceania Rubber and Plastic Products 0.9 Eastern Asia Rubber and Plastic Products 5.6 Western Europe Rubber and Plastic Products 19 |

| Company Certifications | ISO 9001-2008; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | 51% - 60% |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | |

Send your message to us

Custom Molded EPDM

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Pieces pc

- Supply Capability:

- 2000 Pieces per Day pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords