Rubber Profile Product (Silicone CR NBR EPDM)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Meters m²

- Supply Capability:

- 10000 Meters per Day m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

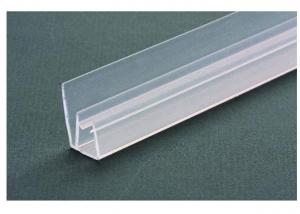

Product Description of Rubber Profile Product (Silicone CR NBR EPDM)

1.Professional OEM & Exporter

2.Professional service.Custom is God

3.Favorable price & good quality

Type of Rubber Profile Product (Silicone CR NBR EPDM)

1.Sponge/Foam Extrusion.

2.Solid/compact Extrusion.

3.Co-extruded seal strip.

4.PVC&Rubber compound extrusion.

5.All these can be with metal insertion.

Features of Rubber Profile Product (Silicone CR NBR EPDM)

Widely used in industry,agriculture,including building,automotive sealing profiles, sealing or decorating of windows, doors, curtain walls, cars etc,avoiding dust,water or air to leak inside the cabin,as

it's good ozone-resistant,chemical resistant,Weather&temperature resistant and has excellent

appearance in flexibility Anti-aging, antiradiation.

Range of Rubber Profile Product (Silicone CR NBR EPDM)

Manufacture wide range of rubber profile,rubber seals,rubber strip, tubing, cord or custom rubber extrusion

shapes for Auto industry,mechanical,construction,etc ,the extrusions also can be made in PVC. Our rubber

extrusion includes but not limited , D sponge Seal, Rubber bulb, rubber U channel, T section seal, Edge Trim, Flock

lined rubber, flat square sponge rubber, window rubber,weather strip etc.Custom design could be available.

General data of Rubber Profile Product (Silicone CR NBR EPDM)

Material: EPDM, Nitrile(NBR), Neoprene(CR), Silicon, Viton, SBR, Natual rubber and various other basic raw materials.

Hardness: From 35 to 85 Share A.

Temperature resistance:-50 to +260 Degrees Centigrade (up to 300C for short periods).

Various color are available,like black,red,white,blue.etc.

Grade:Industrial grade;Food grade(FDA approval).Medical grade.

Size available:1mm to 150mm high and width

Length:continous.

Different sections as per your sample or drawings,do believe that we can supply competitive price &quality with best service.

- Q:What kind of grease can be used in the Great Wall sunroof rubber grease?

- We should use synthetic lubricating grease, the current public car use is hotolube or Kluber tiger, leopard peach one hundred and thirty grams of toothpaste packaging, this grease to food safety standards, low temperature resistance, water resistance, durability, long lasting lubrication.Do not use Vaseline for skylights lubrication, low melting point of Vaseline, about forty degrees on the melting of volatile, and summer car temperature reached forty or fifty degrees. Should not use oil or ordinary butter, winter will freeze, durability is not enough, the distribution of harmful odor.

- Q:What are the tyres made of and what is the manufacturing process?

- Process two: plastic parts preparation processThe plastic parts preparation process consists of 6 main sections. In this process, all semi-finished rubber components that make up the tire will be prepared, some of which are initially assembled.

- Q:What are the uses of rubber materials in automobiles?

- Hose for automobile. No matter what the car has a lot on the root rubber tube, such as radiator pipe, air-conditioning pipe, water pipe, gas pipe and so on, because these tubes need to experience vibration and bumps in the car environment, so we have various performance requirements, it must be used in automotive rubber parts.

- Q:How to prevent aging of automobile rubber parts?

- Rubber, however, is an unsaturated olefin polymer. According to South rubber technical personnel, the characteristics of rubber is rubber and its products easily influenced by their own or external factors in the processing, storage and use of the process, thus the structure or component damage, the impact of the use value and the range of application. This phenomenon is called Rubber Aging by rubber and plastic industry. A variety of aging of natural rubber products such as rubber, variety, or surface sticky, brittle, hard, cracking, delamination and mildew; solubility, rheological property, heat resistance and cold resistance change; dielectric constant, surface resistance and conductivity changes etc..

- Q:What oil rubber will not deteriorate in the automobile brake pump?

- That leather case is for dust proof. When braking, the brake pad and brake hub friction, a friction, there will be very fine, very fine iron powder, like dust so fine

- Q:The car is rubber tube and fetal pad or cooked? The raw or cooked well, what is the difference?

- Glue: rubber at high temperature after vulcanization molding, called "glue"".

- Q:Can polyurethane rubber be used for automobile tires?

- Tolerable。 This technology is not yet available.

- Q:How to properly clean automobile engines, rubber and tires and other parts?

- The procedures for cleaning and beautifying the engine are as follows:(1) before scrubbing, remove dust or fine sand with a brush or jet gun.(2) be sure to spray detergent onto a sponge or brush before wiping it.(3) the black resin parts can be cleaned and protected by plastic parts, so that the wax can be renewed. If it is sprayed directly, it may be sprayed into the place where it should not be sprayed.

- Q:The role of particle glue on automobiles

- Functional characteristicsThe corrosion protection of the chassisThe stone guard3 earthquakeThe insulating oilThe sound insulation and noise reductionThe anti drag bottomThe maintenance cost

- Q:The car tire is pressing on the stone, the rubber of the tire is all broken, the heroes see can still use?

- The principle, steps and internal tyre repair patch nail mushrooms are the same, but it finally posted up is not a film, but looks like a mushroom rubber nail, so called nail mushrooms. Remove the root of the mushroom nail from the tire through the damaged part, then cut off the excess part that leaks out, and use the strong glue on the inside. Due to the damaged parts completely blocked, thus preventing water from breakage and damage in tire wire and ply tyre, so is the safest and most reliable method. However, its disadvantages are obvious, that is, the price is relatively high.

1. Manufacturer Overview |

|

|---|---|

| Location | Zhejiang,China (Mainland) |

| Year Established | 2004 |

| Annual Output Value | US$2.5 Million - US$5 Million |

| Main Markets | North America Western Europe |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai,Ningbo |

| Export Percentage | 91% - 100% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English |

| b)Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | 7 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | average |

Send your message to us

Rubber Profile Product (Silicone CR NBR EPDM)

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Meters m²

- Supply Capability:

- 10000 Meters per Day m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products