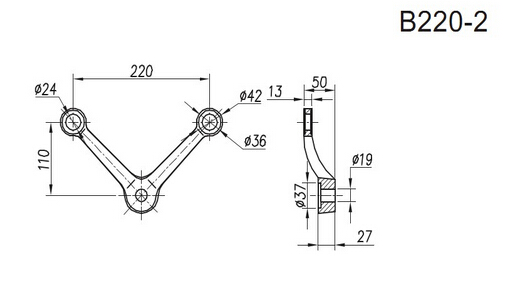

Curtain Wall System Two Arms Spider B220-2

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Name: Curtain Wall System Two Arms Spider A220-2

Specifications

1. curtain wall spider system

2. made by casting

3. with genuine stainless steel

4. laser printing logo available

Table of Chemical Composition (%)

Material: S.S 304 | ||||||||

Carbon | Silicon | Manganese | Phosphorous | Sulfur | Nickel | Chrome | Molybdenum | |

Range | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | ≤8.00-11.0 | ≤18.0-20.0 |

|

Material: S.S 316 | ||||||||

≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | ≤10.0-14.0 | ≤16.0-18.0 | ≤2.0-3.0 | |

Product Picture:

Other types spider in B220 Series:

B220-21 B220-1

B220-4 B220-11

Project Picture:

- Q: A set of curtain wall point of the stainless steel access to the claws, including what?

- Stainless steel access pawls generally include the shuttle paw and the access head, the model has 150 series, 160 series, 200 series, 220 series, 250 series, 300 series, divided into four claws, three claws, 90 degrees two claws, 180 degrees two claws , Long claws, short claws, from the material there are 202 material, 304 material, 316 material and so on! Some of the specific circumstances to be customized!

- Q: Diamond knife can pierce twelve PCT tempered glass?

- Diamond knife is not the glass pierced, but the glass a long mouth, and then stress the broken line above the broken, it is easy to board off. It is very difficult to cut the twelve-piece tempered glass directly.

- Q: What is the connection between the glass room and the stainless steel?

- Stainless steel surrounded by black double-sided adhesive paste, glass pressure on the double-sided adhesive, surrounded by cracks with glass glue or weathering rubber full!

- Q: The production of curtain wall glass splicing claws of the big brand which several!

- In accordance with the light box instructions to open to their company to see their factory has not a basketball court, and inside a few lathes, inside the factory inside the office there are several pieces of claw samples, the production of claw pieces of a machine are not, This scale

- Q: How to do the size of the glass shed with stainless steel claws

- According to the size of the selected splicing claws on the joints.

- Q: What is the splice

- The spliced connector is a fitting for a glass curtain.

- Q: What is the reason for rusting the claws?

- 1, the surface of stainless steel deposits with other metal elements of dust or heterogeneous metal particles attached to the wet air, between the attachment and stainless steel condensate, the two together into a micro-battery, triggering the electrochemical reaction , The protective film is damaged, called electrochemical corrosion. 2, stainless steel surface adhesion of organic juice (such as melon vegetables, soup soup sputum, etc.), in the case of water and oxygen, constitute organic acids, long time to form organic acid corrosion of metal surface. 3, stainless steel surface adhesion containing acid, alkali, salt substances (such as decorative walls of alkaline water, lime water spray test) caused by local corrosion. 4, in the contaminated air (containing a lot of sulfide, oxide, hydrogen oxide atmosphere), in case of condensate, The formation of sulfuric acid, nitric acid, acetic acid liquid point, causing chemical corrosion. The above can cause damage to the surface of the stainless steel protective film, causing corrosion. So, to ensure that the metal surface is permanently bright and not rusty, we recommend: ① must always clean the surface of the decorative stainless steel scrub, remove the attachment, to eliminate the external factors that cause corrosion. ② There is a 201 and 202 stainless steel in the market is easy to rust in the coastal area, suitable for use in industrial pollution and air corrosion environment. ③ beach area to use 304 stainless steel, 304 material can resist seawater corrosion.

- Q: What is the use of borehole during the production of tempered glass?

- Drilling is the need for glass mounting - fixing the glass through the holes.

- Q: What is the difference between double steel safety glass and insulating glass in steel canopy

- The loads of light steel canopy include the weight, wind load, snow load and live load, in which the snow load is not taken into account, the wind pressure is positive or negative, a certain range of negative pressure is beneficial to the structure, the actual calculation Considered separately. Through the comparison, the design and calculation of the most unfavorable conditions of the combination of the dead weight, the wind load and the live load are carried out, including the calculation of the force combination of the glass and steel glass sheds, the calculation of the glass strength and the checking of the glass deflection, and finally the selection of the material The

- Q: How to install the glass canopy

- Install the stainless steel splicing jaws, and then fixed the size of the glass fixed on the splicing claws, and then hit the weathering glue closed glass gap and glass and wall contact with the gap.

Send your message to us

Curtain Wall System Two Arms Spider B220-2

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches