Cuplock Scaffold System for Construction China Manufacture Directly Selling CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details of Cuplock Scaffold System for Construction China Manufacture Directly Selling

Type: Heavy Section Steel

Forming: Welding Products

Standard:

Member:

Trademark:

Connection Form:

Carbon Structural Steel:

Residential Wall Structure:

Type of Steel For Building Structure:

Bs1139, En74 Standard:

Export Markets:

Descriptions of Cuplock Scaffold System for Construction China Manufacture Directly Selling

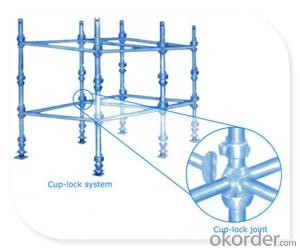

Cuplock is a kind of multi-purpose and versatile modular system scaffolding, suitable for access and formwork support in all types of construction of building & civil engineering projects, offshore projects, etc. This complete galvanized Cuplock system is probably the fastest and most widely preferred scaffolding system. It has flexible erection as straight, curved or circular configuration for both access and support purposes.

Futures of Cuplock Scaffold System for Construction China Manufacture Directly Selling

Multi-functional-with the universal joint and fully interchangeable components, the cuplock system can be used in most construction projects for both formwork and access. It is very versatile and diverse. Use in the shipping industries, oil and gas and aviation industries.

Versatile-Verticals are assembled with horizontals and diagonals using secure fixed cup connections. Its versatility has a distinct advantage to conventional scaffolding methods. A positive & ridged connection of four units is achieved in one single action. The cupock system is very cost effective and can be erected safely and quickly.

Time saving-cuplock scaffold is the solution for temporary structures Performance stages. Small teams can erect it safely and quickly.

Economical-Easily assembled system scaffold saves time and labor costs.

Durable-All components are hot dip galvanized and manufactures to international standard.

Easily Stored-Individual pipe elements can be packed in bundles for easy storage and transportation. For returns, material can be packed in steel racks.

The Main Components of Cuplock Scaffold System for Construction China Manufacture Directly Selling

Verticals

Description

Material

kg/pc

Article No.

9'10" Vertical 3.00m

Q345 φ48.3×3.2

16.90

SC1001 3000

8'2" Vertical 2.50m

Q345 φ48.3×3.2

14.20

SC1001 2500

6'6" Vertical 2.00m

Q345 φ48.3×3.2

11.60

SC1001 2000

4'11" Vertical 1.50m

Q345 φ48.3×3.2

8.90

SC1001 1500

3'3" Vertical 1.00m

Q345 φ48.3×3.2

6.20

SC1001 1000

1' Vertical 0.50m

Q345 φ48.3×3.2

3.50

SC1001 0500

Horizontals

Description

Material

kg/pc

Article No.

10'0" Horizontal 3.05m

Q345 φ48.3×3.2

11.80

SC1002 3048

9'0" Horizontal 2.74m

Q345 φ48.3×3.2

10.70

SC1002 2743

8'2" Horizontal 2.50m

Q345 φ48.3×3.2

9.80

SC1002 2500

7'0" Horizontal 2.13m

Q345 φ48.3×3.2

8.40

SC1002 2133

6'6" Horizontal 2.00m

Q345 φ48.3×3.2

7.90

SC1002 2000

6'0" Horizontal 1.83m

Q345 φ48.3×3.2

7.20

SC1002 1828

5'11" Horizontal 1.80m

Q345 φ48.3×3.2

7.10

SC1002 1800

5'0" Horizontal 1.52m

Q345 φ48.3×3.2

6.10

SC1002 1524

4'11" Horizontal 1.50m

Q345 φ48.3×3.2

6.00

SC1002 1500

4'1" Horizontal 1.25m

Q345 φ48.3×3.2

5.00

SC1002 1250

4'0" Horizontal 1.22m

Q345 φ48.3×3.2

4.90

SC1002 1219

3'6" Horizontal 1.07m

Q345 φ48.3×3.2

4.30

SC1002 1067

3'3" Horizontal 1.00m

Q345 φ48.3×3.2

4.10

SC1002 1000

3'0" Horizontal 0.91m

Q345 φ48.3×3.2

3.80

SC1002 0914

2'11" Horizontal 0.90m

Q345 φ48.3×3.2

3.70

SC1002 0900

8'0" Horizontal 2.44m

Q345 φ48.3×3.2

9.50

SC1002 2438

1'10" Horizontal 0.57m

Q345 φ48.3×3.2

2.40

SC1002 0600

FAQ

1. What is considerations of Scaffolding installation?

There must be a fire protection measures and specialist care, safety personnel patrol inspection when electricity, gas welding work on the scaffold,

(1) scaffold frontage hurtful to prevent falling objects protection is required.

(2) During take down the scaffolding, fencing and warning signs should be set up on the ground, prohibit others person besides the operator

2.What are the certifications of your products?

Certified by SGS, BS1139, EN74, Local Test Report.

3. How long is the warranty period for your product?

Our products warranty is 2 years.

- Q: What's an antonym for the word scaffold?

- Since a scaffold is a bridge/ladder/support used to allow you to span the gap between you and and object you wish to reach, I'd go with barrier.

- Q: Scaffolding installation and precautions?

- The backing plate and the base should be placed on the positioning line accurately.2, when the erection of the column, the outer diameter of the steel pipe is strictly prohibited, the adjacent column of the docking fasteners shall not be in the same height, staggered distance should meet the structural requirements.

- Q: The latest JGJ130-2011 construction fastener type steel pipe scaffolding safety technical specifications, schedule A.0.2 what role, how to correctly use it?

- If the pole height is 5.345m, general 5.30~5.33m, general step according to the self set in advance, such as, 1.8m, 1.5m, and finally, according to the table look-up

- Q: What does Scaffolding mean in the educational talk?

- Scaffolding is the support the teacher provides to lead the student to learn the necessary skill. In a classroom discussion on a literary text, the teacher might scaffold learners by starting questions with concrete answers (found in the text) then asking guiding questions which require more abstract thought (for instance, asking students to make inferences). In other instances, if a concept or skill is too difficult for a student, the teacher may choose to reteach an earlier skill, then provide one-on-one tutoring on the new skill until the student gets it. There are other ways to scaffold. Some students may only need the support of a peer-partner to reach success. Others may need a change in environment (move to a quieter place to work) or a change in material (providing colored transparencies for a dyslexic student during silent reading). Scaffolding is a form of targeted, differentiated support. What you will find over time is that the techniques you use actually serve more than just the intended audience. I have found that scaffolding during classroom discourse helps not just the obviously struggling student, but those who were reluctant to raise their hands or otherwise let me know that they were struggling, too.

- Q: What are the main safety problems when dismantling the scaffold

- 3, the demolition of spare parts to be loaded into the container, with a crane hanging; the steel pipe to be tied to secure, double point lifting, prohibited from high altitude thrown.4, more than six wind (including level six) to stop the construction of mobile scaffolding.

- Q: What are the characteristics of Pankou scaffolding

- Pankou scaffold has the advantages of low cost and high efficiency of the hitherto unknown advantage. Comprehensive consideration of the company's future worries, no need to worry too much about frequent accidents, high cost of substantive issues.

- Q: ...and I'm not really sure what to expect. I know that everyones healing time and pain tolerence is different but just some personal storys would be nice. And before you say it I am aware that there are risks as there are risks with any piercing. so I'm 17 from London and wondering:How old do you have to be to get it done?Does anyone know a reputable place i can get it done?How much will it be?any experiences to share?

- via stretcher you advise gauge, ultimate? i've got in no way heard it suggested as a stretcher before, yet that would desire to easily be only an area slang differing style venture. besides, i think of gauges are suited or perhaps lovable in the event that they are smaller. bigger ones are too off-putting and that i might in no way do it myself. i like the belief of an commercial piercing nevertheless. i admire those. i myself % to get one sometime quickly. i've got needed one for a mutually as. i does no longer probably individually get a gauge, yet whilst that's what you sense works via all skill get one. i think of the commercial piercing is adequate on that is very own. i do no longer think of it should be accompanied via a gauge. besides, it sounds to be such as you needed the commercial piercing first, so which you may desire to start with that.

- Q: i had my scaffold piercing done in the summer holidays and wen i went back to school (currently in my last year) they told me to take it out so i had to go back to the piercer. They changed the bar to two clear retainers in the holes so they wouldn't heal, now it hurts all the time and is red with a bubble on the top of my ear, any suggestions as to what i should do? :/

- regularly clean it with salty lukewarm water and cover it up with tape

- Q: Okay so I got a scaffold piercing about 5 days ago now. I've been cleaning it with Claire's piercing stuff. What I do is I pour it onto a little bit of loo roll and squeeze it all out on where the holes are. I have not been twisting it at all, but my friend told me that I should soak it in warm salty water and twist it twice a day. I have no idea what to do now as I have researched it and some people say that I shouldn't twist it because it will drag more bacteria into it and could get it infected. Also I have massive scabs around both ends of the bar, I've tried to pick them off as they are pretty uncomfortable, but it didn't work as they are rock solid, so how do I get these off? I have no idea what to do, my piercer didn't say anything about twisting it just cleaning it twice a day. Oh and if it helps I'm 13:) Thanks. X

- Why are you using Claire's crap? You need to be doing sea salt soaks twice a day for 5-10 minutes each soak with 1/4th of a teaspoon of non-iodized sea salt to 8oz of hot water. Don't twist them as that drags in crust and bacteria and tears up the inside of the piercing. Stop trying to pick stuff off from your ear and go have a reputable piercer check out the scabbing, it could be crust it could be something wrong. If your piercer didn't tell you to do sea salt soaks to keep it clean go to a better piercer.

- Q: how did they turn the cells into a polymer for the heart scaffold ?

- May have misunderstood. The heart is gently stripped of cells by using a detergent - this leaves the extracelllular matrix - a polymer of collagen - inert and insoluble. New cells (stem cells) will then be added to the structure to repopulate it with living heart muscle which gain coordination and structure from the matrix.

Send your message to us

Cuplock Scaffold System for Construction China Manufacture Directly Selling CNBM

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords