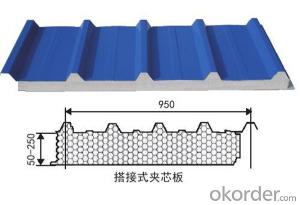

Corrugated color coated Galvanized steel from China, CNBM, fast delivery

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1) AVAILABLE DESIGNATION OF (Prepainted galvanized steel coils) printed PPGI coils

Quality Q/BQB 440-2003 JIS G3312-1994 EN 10326-2004 ASTM A653-02a

EN 10327-2004 (BASE PLATE)

(BASE PLATE)

Commercial Steel TDC51D CGCC DX51D+Z/AZ CS Type A/B/C

Forming Steel (TSt01,TSt02,TSt03) CGCD1 FS Type A, Type B

Drawing TDC52D /TDC53D - DX52D+Z/AZ DDS TYPE A/C

Steel DX53D+Z/AZ

Structural TS280GD(TStE28) CGC400 S280D+Z/AZ SS275

Steel TS350GD(TStE34) CGC440 S350D+Z/AZ SS340 Class1

2) OUR SPECIFICATION OF (Prepainted galvanized steel coils) printed PPGI coils

Available Size:

Manufacturer Thickness Width Length of plate Inner diameter of coil

JIANGSU HUIYE STEEL SHEET CO.,LTD 0.2-1.2mm 800/914/1000/1200/1219/1250mm 1000-6000mm 508mm/610mm

Coated Mass OF (Prepainted galvanized steel coils) printed PPGI coils:

Base plate Available Coated Mass(g/m^2)

Galvanized Steel 80, 100, 120, 160, 180

Galvalume Steel 50, 70, 150

Available Painting OF (Prepainted galvanized steel coils) printed PPGI coils:

Category of Painting Item Code

Polyester PE

High-durability polyester HDP

Silicon modified polyesters SMP

Polyvinylidene fluoride PVDF

Easy-Cleaning —

Painting Thickness Top side: 20+5microns;

Bottom side: 5~7microns.

Color System Produce according to RAL Color System or as per buyer’s color sample.

Painting structure Top surface Bottom surface

Primer coating No coating 1/0

Primer coating Primer coating 1/1

Primer coating + Finish coating No coating 2/0

Primer coating + Finish coating Primer coating or single back coating 2/1

Primer coating + Finish coating Primer coating + Finish back coating 2/2

- Q: Are steel sheets heat resistant?

- Yes, steel sheets are heat resistant. They have a high melting point and can withstand significant levels of heat without deforming or losing their structural integrity.

- Q: Can steel sheets be used for kitchen appliances?

- Yes, steel sheets can be used for kitchen appliances. Steel is a durable and versatile material that is commonly used in the manufacturing of various kitchen appliances such as refrigerators, ovens, and dishwashers. It offers excellent heat resistance, is easy to clean, and provides a sleek and modern look to the appliances.

- Q: What is the standard size of a steel sheet?

- The standard size of a steel sheet can vary depending on its intended use and industry standards. However, common sizes for steel sheets range from 4x8 feet to 5x10 feet.

- Q: How durable are steel sheets?

- Steel sheets are highly durable and known for their strength and resilience. They can withstand heavy loads, extreme temperatures, and harsh environmental conditions, making them ideal for various applications in construction, manufacturing, and automotive industries.

- Q: How much is 2 millimeters per square meter?

- The performance of carbon steel mainly has the following deficiencies:(1) hardenability is low. Under normal circumstances, the maximum quenching diameter of carbon steel water quenching is only 10mm-20mm.(2) strength and yield strength are relatively low, such as the s of ordinary carbon steel Q235 is 235MPa, while that of low alloy structural steel 16Mn is 360MPa and above s. The sigma S / sigma B of steel 40 is only 0.43, much lower than that of alloy steel.(3) the stability of tempering tempering stability, carbon steel in quenching and tempering treatment, in order to ensure the high strength with the tempering temperature is lower, so the toughness of the steel is lower; in order to ensure good toughness, with high tempering temperature strength is low, the mechanical properties of carbon steel level is not high.(4) stainless steel can not meet the requirements of special performance. Carbon steel is often poor in oxidation resistance, corrosion resistance, heat resistance, low temperature resistance, wear resistance and special electromagnetic properties, and can not meet the needs of special performance.

- Q: What are the different types of surface patterns available for steel sheets?

- There are several different types of surface patterns available for steel sheets, including smooth, textured, embossed, diamond, and perforated patterns.

- Q: Are the steel sheets resistant to atmospheric corrosion?

- Generally, steel sheets possess resistance against atmospheric corrosion. However, the degree of resistance may differ depending on the specific steel type employed and the environmental conditions it encounters. For example, stainless steel sheets exhibit high resistance owing to the inclusion of chromium, which generates a safeguarding oxide layer on the surface. Conversely, carbon steel sheets might be more vulnerable to corrosion if they lack proper coating or treatment. Moreover, the presence of pollutants, humidity, and other atmospheric aspects can also impact the corrosion resistance of steel sheets. It is, therefore, crucial to take into account these factors and select the suitable steel type and protective measures to ensure enduring resistance against atmospheric corrosion.

- Q: Are steel sheets suitable for manufacturing HVAC grilles?

- Yes, steel sheets are suitable for manufacturing HVAC grilles. Steel is a popular material choice for HVAC grilles due to its strength, durability, and versatility. It is able to withstand the high temperatures and air pressures often encountered in HVAC systems. Steel sheets can be easily formed into various shapes and sizes to meet specific grille designs and requirements. Additionally, steel is resistant to corrosion, which is important for maintaining the longevity and performance of HVAC grilles in both indoor and outdoor environments. Overall, steel sheets provide the necessary properties and characteristics needed for manufacturing high-quality HVAC grilles.

- Q: Are steel sheets suitable for high-temperature insulation?

- No, steel sheets are not suitable for high-temperature insulation as they have poor thermal insulation properties and can conduct heat easily.

- Q: Are steel sheets resistant to pests and insects?

- Yes, steel sheets are generally resistant to pests and insects due to their non-porous and durable nature.

Send your message to us

Corrugated color coated Galvanized steel from China, CNBM, fast delivery

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords