Converter Continuous Casting Square Steel Billet Q235 Q275 Q345 for Construction

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

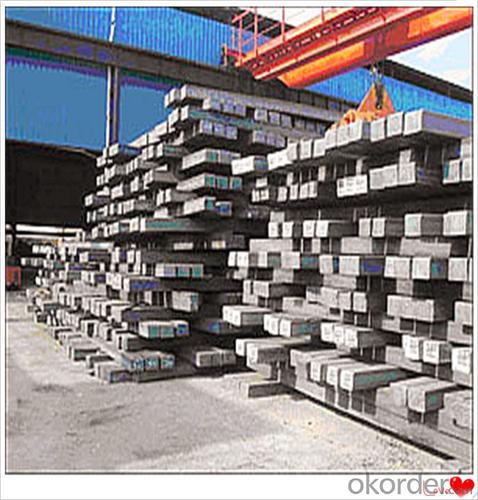

Converter Continuous Casting Square Steel Billet Q235 Q275 Q345 for Construction

Description

Reference Price:$260/ton Mn 0.3%-0.6%

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also known for their malleability and ductility, especially when exposed to varying temperatures during shaping and molding.

Processing of Steel Billet

Steel billets are considered fresh and raw, and they must undergo a series of manufacturing processes before they can be used for various purposes. Billets are made by means of freezing molten liquid, and are later exposed to extremely low temperatures in order to allow the metal to take shape and solidify in chemical structure. The temperature manipulates the metal's physical properties, and tones its strength and durability. The subsequent processes provide the metal's curved mold design so that it can fit the allotted space provided by other machines, which complete the finishing procedures.

Images

Technical Data

Size:100*100,120*120,150*150,130*130

Mn: 0.3%-0.6%

C: 1%

Cr:0.1%

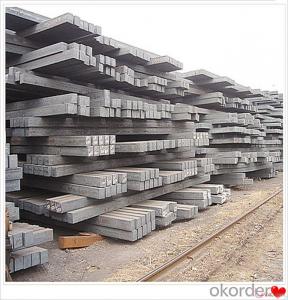

Packaging

cargo ship or container

usually container price will add 15USD per ton

RFQ

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

4)Do you have your own QC department?

Yes, we have, our QC department will inspect the goods during the process of mass production and after completion of production.

hot sale!!! steel billets/ mild steel bar/ billet steel

(1): High quality steel with reasonable price.

(2): Wide excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Trial order can be done in one week.

(6): Samples can be provided as your requirements.

If you are interested in our products, please don't hesitate to contact me.

Your any inquiry will be appreciated and we will offer you a rock-bottom price.

- Q: What are the common defects in steel billets during continuous casting?

- Some common defects in steel billets during continuous casting include cracks, surface defects such as scabs or scale, internal defects like inclusions or porosity, and dimensional irregularities such as tapering or bulging.

- Q: What is the impact of impurities on the quality of steel billets?

- The presence of impurities in steel billets can significantly impact their quality. Impurities can weaken the structural integrity of the steel, reduce its toughness, and make it more prone to cracking or failure. They can also affect the steel's ability to resist corrosion, resulting in reduced durability and lifespan. Additionally, impurities can interfere with the steel's ability to be machined or welded, limiting its usability in various industries. Therefore, controlling and minimizing impurities in steel billets is crucial to ensure high-quality and reliable end products.

- Q: How do steel billets contribute to the manufacturing of consumer electronics?

- Steel billets are an essential raw material in the manufacturing of consumer electronics as they are used to produce various components and casings. These billets are melted and shaped into specific forms, such as sheets or bars, which are then used to construct frames, chassis, and other structural parts of electronic devices. The strength, durability, and malleability of steel make it an ideal material for ensuring the integrity and longevity of consumer electronics, thereby contributing to their overall quality and performance.

- Q: How do steel billets contribute to the manufacturing of construction equipment?

- Steel billets play a crucial role in the manufacturing of construction equipment. These billets are essentially semi-finished steel products that have been cast into a specific shape and size. They are typically rectangular or square in shape and serve as the starting point for further processing. One of the main ways in which steel billets contribute to the manufacturing of construction equipment is by providing a high-quality raw material. Steel is known for its exceptional strength, durability, and resistance to various environmental factors. By using steel billets, manufacturers can ensure that the construction equipment they produce will be able to withstand the harsh conditions and heavy loads that are often encountered in the construction industry. Steel billets are also used to produce various components of construction equipment. These components can include frames, beams, brackets, and other structural elements. By using steel billets, manufacturers can easily shape and form these components to meet the specific design requirements of the equipment. This flexibility allows for the creation of equipment that is not only strong and durable but also lightweight and efficient. Furthermore, steel billets are often used in the manufacturing of construction equipment due to their cost-effectiveness. Steel is a highly recyclable material, which means that it can be reused and repurposed multiple times without losing its properties. This makes steel billets a sustainable and environmentally friendly choice for manufacturers. In summary, steel billets are an essential component in the manufacturing of construction equipment. They provide a high-quality raw material that is strong, durable, and resistant to various environmental factors. Steel billets also allow for the production of customized components that meet specific design requirements. Additionally, their cost-effectiveness and recyclability make them a sustainable choice for manufacturers. Overall, steel billets contribute significantly to the production of construction equipment, ensuring that it meets the highest standards of quality and performance.

- Q: What are the different methods of steel billet surface polishing?

- There are multiple techniques available for polishing the surface of steel billets, each with its own benefits and uses. These techniques consist of mechanical polishing, chemical polishing, electrochemical polishing, and abrasive blasting. Mechanical polishing is a widely employed method that employs abrasive materials to eliminate surface flaws and create a smooth outcome. It can be done manually using sandpaper or with the aid of machinery like buffing machines or belt sanders. This technique effectively removes scratches, oxidation, and other imperfections on the surface, resulting in a polished and reflective appearance. Chemical polishing is a non-mechanical approach that relies on chemical reactions to eliminate surface flaws. It involves immersing the steel billet in a chemical solution that dissolves a thin layer of the material, resulting in a smoother surface. Chemical polishing is commonly used for intricate or delicate components, as it can achieve a high level of precision and uniformity. Electrochemical polishing, also known as electropolishing, is a technique that combines chemical and electrical processes to polish the surface of the steel billet. It involves immersing the billet in an electrolyte solution and applying an electric current. The electric current removes microscopic peaks and imperfections, resulting in a smoother and brighter surface. Electrochemical polishing is frequently used for stainless steel billets due to its ability to eliminate surface contaminants and enhance corrosion resistance. Abrasive blasting, also referred to as sandblasting, is a technique that utilizes high-pressure air or water to propel abrasive materials onto the surface of the steel billet. This process effectively eliminates rust, scale, and other surface contaminants, resulting in a clean and textured finish. Abrasive blasting can be performed using various abrasive materials such as sand, steel shot, or glass beads, depending on the desired surface finish. In conclusion, the various techniques for polishing the surface of steel billets include mechanical polishing, chemical polishing, electrochemical polishing, and abrasive blasting. Each technique offers its own advantages and applications, providing a range of options to achieve the desired surface finish for steel billets.

- Q: What are the main challenges in the distribution of steel billets?

- The distribution of steel billets faces several challenges that can impact the overall efficiency and effectiveness of the process. Some of the main challenges include: 1. Logistics and transportation: Steel billets are heavy and bulky, requiring specialized equipment and handling. The transportation of these materials can be challenging, especially in remote areas or regions with poor infrastructure. The coordination of transportation modes, scheduling, and ensuring timely delivery can be a complex task. 2. Storage and inventory management: Steel billets often need to be stored for a certain period of time before they are processed or further distributed. Proper storage facilities with adequate capacity and appropriate conditions, such as temperature control and protection from moisture, are crucial. Managing inventory levels to avoid excess or shortage is also a key challenge. 3. Quality control: Ensuring the quality of steel billets throughout the distribution process is essential. Any damage or contamination during handling or transportation can affect the properties and performance of the final steel products. Implementing strict quality control measures, inspections, and monitoring processes is crucial to maintain the desired quality standards. 4. Market fluctuations and demand forecasting: The steel industry is highly influenced by market fluctuations and demand volatility. Accurate demand forecasting can be challenging due to various factors such as economic conditions, construction activities, and geopolitical events. Failure to predict demand accurately can result in excess inventory or stockouts, leading to financial losses. 5. Environmental regulations and sustainability: The steel industry is under increasing pressure to reduce its environmental impact and embrace sustainable practices. Compliance with environmental regulations, such as emissions control and waste management, can present challenges in distribution. Implementing eco-friendly transportation methods and exploring sustainable packaging options can help address these challenges. 6. Global competition and pricing: The distribution of steel billets is affected by global competition and pricing pressures. Steel producers and distributors must constantly analyze and adapt to market trends, competitor behavior, and price fluctuations. Maintaining competitive pricing while ensuring profitability can be a significant challenge in the steel billet distribution business. Overcoming these challenges requires coordination among various stakeholders in the supply chain, including steel manufacturers, distributors, logistics providers, and end-users. Continuous improvement, technological advancements, and effective communication are essential to mitigate these challenges and optimize the distribution of steel billets.

- Q: How do steel billets contribute to the overall cost-effectiveness of a project?

- Steel billets contribute to the overall cost-effectiveness of a project in several ways. Firstly, steel billets are the starting material for various steel products, such as beams, bars, and sheets. By using steel billets, manufacturers can produce these products in a cost-effective manner, as billets are usually cheaper than finished steel products. Moreover, steel billets allow for efficient use of resources. They can be easily melted down and molded into different shapes and sizes, minimizing waste during the production process. This flexibility reduces the amount of raw material required, leading to cost savings. Furthermore, steel billets have excellent strength and durability properties. By using steel billets in construction projects, engineers can ensure that the structures are sturdy and long-lasting. This helps to reduce maintenance and repair costs over time, making the project more cost-effective in the long run. Additionally, steel billets are readily available in the market, making them a cost-effective choice for projects with tight timelines. Manufacturers can easily source steel billets from various suppliers, ensuring a steady supply of material for the project. Lastly, steel billets contribute to cost-effectiveness through their recyclability. Steel is one of the most recycled materials globally, and using recycled steel billets can significantly reduce the cost of production. Recycling steel billets also helps to minimize the environmental impact of a project, making it a more sustainable and cost-effective option. Overall, steel billets play a vital role in the cost-effectiveness of a project by providing a cost-effective starting material, minimizing waste, ensuring durability, offering availability, and promoting recycling.

- Q: How are steel billets used in the manufacturing of valves and pumps?

- Valves and pumps require steel billets, which are necessary raw materials in their manufacturing process. These billets are cast into specific shapes, typically squares or rectangles, and serve as the foundation for producing valves and pumps. To make valves, steel billets are first heated and then forged or rolled into the desired shape. The billets undergo various processes like cutting, drilling, and machining to create different valve components, including the body, bonnet, disc, stem, and seat. These components are then assembled to form the valve, which controls the flow of fluids or gases in a system. Similarly, in pump manufacturing, steel billets are heated and shaped to create essential parts such as impellers, casings, shafts, and housings. These parts are then assembled to construct a pump, responsible for transferring fluids or gases from one location to another. The use of steel billets in valve and pump manufacturing is crucial due to steel's inherent properties. Steel is highly valued for its strength, durability, and resistance to corrosion, making it ideal for applications in industries where valves and pumps face high pressures, temperatures, and corrosive environments. Moreover, steel's versatility allows manufacturers to customize valves and pumps in terms of size, shape, and specifications to meet the specific requirements of diverse industries and applications. This adaptability ensures that valves and pumps made from steel billets can perform reliably and efficiently in various environments and conditions. In conclusion, steel billets play a vital role in the manufacturing of valves and pumps. Through forging, shaping, and assembly processes, steel billets are transformed into essential components that constitute these crucial industrial devices. The use of steel guarantees the strength, durability, and corrosion resistance needed for valves and pumps to function effectively and endure demanding operational conditions.

- Q: What does the billet of the steel plant refer to?And steel what is the difference?

- The main deformation of reinforced by ribs, binding capacity larger and concrete, so it can better withstand external force. Steel is widely used in all kinds of building structure, especially for large, heavy, light and thin wall structure of high-rise building.

- Q: What are the different types of steel billet casting defects?

- There are several types of steel billet casting defects, including surface defects like cracks, laps, and scabs, as well as internal defects such as shrinkage cavities, porosity, and inclusions.

Send your message to us

Converter Continuous Casting Square Steel Billet Q235 Q275 Q345 for Construction

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords