Heavy Dull Aluminum Baking Sheets - Continuous Casting Aluminum Circle for Pot

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

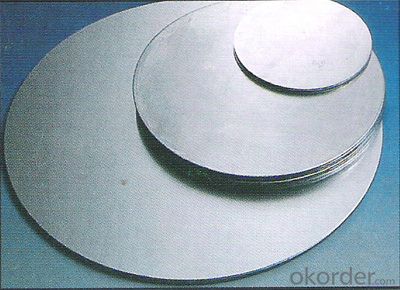

1.Structure of Continuous Casting Aluminium Circle for Pot

Continuous Casting Aluminium Circle for Pot is one semi-finished aluminium material. This Aluminium Circle is widly used to produce aluminium pot, especially for spinning The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Continuous Casting Aluminium Circle for Pot

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4. Product Specification

| Alloy | Temper | Thickness | Diameter | Weight |

| AA1050 | H14 | 0.2MM-2MM | 100MM-1000MM | 2 TONS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: How can I make aluminum oxide?

- It turns out to be surprisingly difficult to do, because aluminum forms a skin of oxide which retards further oxidation. One way might be to react aluminum with sulfuric acid, getting aluminum sulfate in solution. Treat this with barium hydroxide; barium sulfate will precipitate out, leaving aluminum hydroxide in solution. Dry this and heat it, driving off the hydroxide as water and leaving aluminum oxide. I haven't tried this, so cannot guarantee that it will work.

- Q: What is the lifespan of an aluminum sheet?

- The lifespan of an aluminum sheet can vary depending on various factors such as the grade of aluminum, the thickness of the sheet, the environment it is exposed to, and the level of maintenance it receives. Generally, aluminum sheets are known for their durability and long lifespan. Aluminum is a corrosion-resistant metal, meaning it can withstand exposure to moisture and other environmental elements without deteriorating as quickly as other materials. This makes aluminum sheets highly resistant to rust and corrosion, which can significantly extend their lifespan. In general, aluminum sheets can last anywhere from 20 to 50 years or even longer. However, it is important to note that this estimate may change based on the specific application and conditions the sheet is subjected to. For example, aluminum sheets used in outdoor applications, such as roofing or siding, may have a shorter lifespan due to exposure to harsh weather conditions such as UV radiation, extreme temperatures, and heavy rainfall. To maximize the lifespan of an aluminum sheet, proper maintenance and care are crucial. This includes regular cleaning to remove any dirt or debris that can accumulate and potentially cause damage. Additionally, applying protective coatings or treatments can further enhance the sheet's resistance to corrosion and extend its lifespan. Overall, when properly maintained and used in the appropriate applications, aluminum sheets can have a long lifespan, making them a reliable and cost-effective choice for various industries and purposes.

- Q: What is the thickness of an aluminum sheet?

- The thickness of an aluminum sheet can vary depending on its specific application and desired properties. Standard aluminum sheet thicknesses can range from 0.2 millimeters (0.008 inches) to several millimeters (0.1 inches or thicker).

- Q: This question asks about the various types of paint that can be used specifically for aluminum sheets, indicating an interest in paint compatibility and options for this particular material.

- <p>There are several types of paints suitable for aluminum sheets, each offering unique properties. These include: 1. Acrylic Paints - Water-based, easy to apply, and offer good adhesion. 2. Epoxy Paints - Known for their durability and chemical resistance, they provide a strong bond to the metal. 3. Enamel Paints - Provide a hard, glossy finish and are resistant to chipping and scratching. 4. Polyester Paints - Offer excellent durability and UV resistance, making them suitable for exterior applications. 5. Powder Coatings - Applied electrostatically, they provide a tough, scratch-resistant finish. 6. Specialty Paints - Such as heat-resistant or anti-corrosive paints, designed for specific industrial applications. The choice of paint depends on the application, desired finish, and environmental conditions.</p>

- Q: Can aluminum sheets be used for cladding?

- Yes, aluminum sheets can definitely be used for cladding. Aluminum is a popular choice for cladding due to its many beneficial properties. It is lightweight, durable, corrosion-resistant, and has excellent thermal and acoustic insulation properties. It is also highly malleable, allowing for various design possibilities. Aluminum cladding is commonly used in both residential and commercial buildings to provide protection, enhance aesthetics, and improve energy efficiency.

- Q: Can aluminum sheets be used for storage tanks?

- Indeed, storage tanks can make use of aluminum sheets. Due to its lightweight nature and resistance to corrosion, aluminum proves to be a fitting option for the containment of diverse substances, including water, chemicals, and fuel. Its remarkable durability allows it to endure even the harshest environmental conditions. Moreover, constructing and maintaining aluminum tanks is comparatively straightforward. Nonetheless, it is crucial to take into account the specific necessities of the substance being stored and seek guidance from professionals or engineers to ascertain that aluminum sheets are the suitable selection for the given storage tank.

- Q: What rules or guidelines exist for using recycled aluminum sheets in construction projects?

- <p>Yes, there are regulations and guidelines regarding the use of recycled aluminum sheets in construction. These often include standards for material quality, safety, and environmental impact. The American Society for Testing and Materials (ASTM) and the Aluminum Association provide specifications for recycled aluminum alloys used in construction. Compliance with building codes and local regulations is essential. Additionally, recycled aluminum must meet performance and safety standards equivalent to those of new materials. It's crucial to check with local building authorities and consult the latest industry standards to ensure compliance when using recycled aluminum in construction.</p>

- Q: 1) Aluminum ore is not formed in Quebec (why not?) 2)but aluminum ore is smelted into aluminum in Quebec. Why?

- The okorder

- Q: 5052 aluminum plate and LY12 aluminum plate is the same?

- The 5052 series is aluminum magnesium alloy, the magnesium alloy belongs to the lower density alloy, the 5052 alloy aluminum plate density is 2.68LY1, LY2, LY4, LY6 series for nickel chromium alloy, is a hard aluminum density 2.76

- Q: How do aluminum sheets perform in terms of weather resistance?

- Aluminum sheets are highly weather-resistant due to their natural oxide coating, which provides excellent corrosion resistance against various weather elements such as rain, snow, UV radiation, and temperature changes. This oxide layer acts as a protective barrier, preventing the metal from further oxidation and degradation. Consequently, aluminum sheets retain their structural integrity and appearance even when exposed to harsh weather conditions for extended periods.

Send your message to us

Heavy Dull Aluminum Baking Sheets - Continuous Casting Aluminum Circle for Pot

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords