Concrete Pumping Sylinder (ZOOMLION ) I.D.:DN205 Length:2284MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

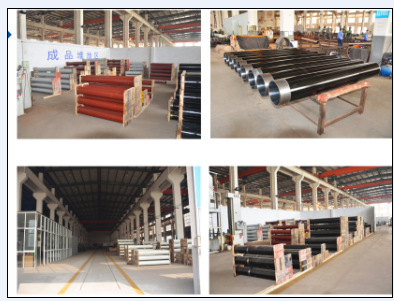

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

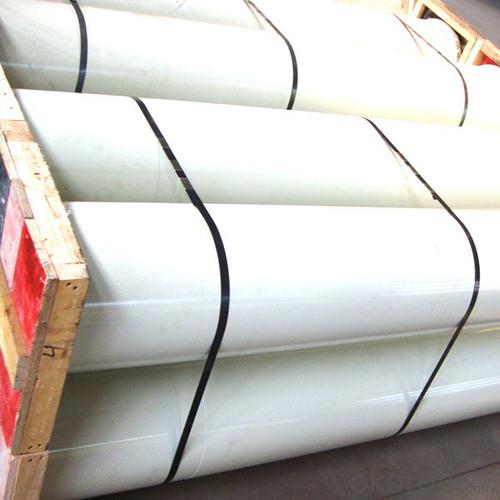

TheConcrete Pumping Sylinder (ZOOMLION ) I.D.:DN205 Length:2284MM normally made by steel material No. C45. according to customer’s requests, and also package in bundles or nude packing directly put into container.

Scope of Application of the Cylinders

The Concrete Pumping Sylinder (ZOOMLION ) I.D.:DN205 Length:2284MM is a Cylinder pumping for combined use with other concrete pumps parts in concrete pumping operations. It can be widely used in the construction of various types of concrete structures like industrial and civil buildings, bridges, roads, and other types of infrastructure.

This Cylinder Cylinder DN205*2284 can only be used in Zoomlion concrete pumps construction operations, but not in any other operations, like dragging, moving, or hoisting heavy articles or personnel. The pipe is also not allowed to be used in any location where any combustible or explosive material exists or a cave-in may occur.

Specifications:

Concrete Pumping Sylinder (ZOOMLION ) I.D.:DN205 Length:2284MM

1. Capacity: 60,000~80,000cbm

2. Size: DN180, DN200, DN230.DN250

3. Material: C45

4. quenching and tempering to improve the hardness to HB241-280

5. inner wall chrome thickness is 0.25-0.30mm, hardness HV820-900.

6. Brand: ZOOMLION

7. Capacity: 60,000~80,000cbm

Product Advantages:

OKorder's Cylinders DN205*2284 Channels are durable, strong, and safety.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (10-20 days)

Reliable performance

Easy to weld

High safety.

· Professional Service

· Competitive pricing

Measuring of wall thickness from the outside

Low purchase cost

FAQ:

Q1: How long about delivery time about Concrete Pumping Sylinder (ZOOMLION ) I.D.:DN205 Length:2284MM ?

A1: Normally we keep the raw materials for old customers and sometime we also keep stock products to make sure delivery time in any emergency cases.

Q2: How do we guarantee the quality of our Cylinders DN205*2284 ?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will book the vessel for goods. The specific shipping date is dependent upon international and government factors, but is typically10 to 30 workdays.

Q4: If we can produce Cylinders DN205*2284 according to customers request?

A4: Yes, we can produce Cylinders DN205*2284 according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world.

- Q: Are there any specific guidelines for the installation of pistons or cylinders in concrete pump spare parts?

- Yes, there are specific guidelines for the installation of pistons or cylinders in concrete pump spare parts. It is important to follow manufacturer instructions and recommendations for proper alignment, lubrication, and torque specifications during installation. Additionally, regular inspection and maintenance are crucial to ensure optimal performance and longevity of the pump parts.

- Q: Are there any specific guidelines for the disposal of hydraulic fluids used in concrete pump spare parts?

- Yes, there are specific guidelines for the disposal of hydraulic fluids used in concrete pump spare parts. These guidelines typically vary depending on local regulations and environmental laws. It is generally recommended to follow the manufacturer's instructions for proper disposal methods. This may involve recycling the hydraulic fluids or disposing of them at designated waste management facilities to ensure minimal environmental impact.

- Q: Are there any specific guidelines for the disposal of packaging materials of concrete pump spare parts?

- Yes, there are specific guidelines for the disposal of packaging materials of concrete pump spare parts. It is generally recommended to follow the local waste management regulations and guidelines provided by the respective authorities. Firstly, it is important to separate the different types of packaging materials such as cardboard boxes, plastic wraps, foam inserts, and any other materials used for packaging the concrete pump spare parts. This will enable efficient recycling or proper disposal of each material. Cardboard boxes can typically be recycled by flattening them and placing them in the designated recycling bins. Plastic wraps should also be separated and disposed of in specific recycling bins for plastics. Foam inserts, which are commonly used for protecting the spare parts, may not be recyclable in all areas and should be checked for specific recycling instructions. If recycling is not possible, foam inserts can be disposed of in regular waste bins. It is important to ensure that all packaging materials are free from any residual concrete or other hazardous substances before disposal. Any contamination should be properly cleaned or removed to prevent environmental pollution. If the packaging materials cannot be recycled or disposed of through regular waste management methods, it is recommended to contact local recycling centers or waste management facilities to inquire about specific disposal options for these materials. They may provide guidance or accept these materials for specialized processing or disposal. Overall, it is crucial to prioritize responsible waste management practices and comply with the specific guidelines provided by local authorities to ensure the proper disposal of packaging materials of concrete pump spare parts.

- Q: What are the preventive measures for concrete pump?

- Pumping concrete should meet the requirements of pumping, and if necessary, test pump to determine the pump concrete mix ratio.

- Q: How can the concrete pump be installed and used?

- Operation should be carried out before the examination, to confirm the normal electrical equipment and instrumentation, each part of the switch button, the handle in the correct position, the mechanical part of the fastening point is firm and reliable, and the chain belt tightness to meet the requirements, the normal operation of the transmission parts

- Q: How can a faulty accumulator affect the pumping efficiency?

- A faulty accumulator can significantly affect the pumping efficiency in a variety of ways. Firstly, an accumulator is a device that stores energy in the form of pressurized fluid. It helps regulate the flow of fluid in a hydraulic system and provides additional power when needed. If the accumulator is faulty, it may not be able to store or release fluid properly, leading to an imbalance in the hydraulic system. This imbalance can cause fluctuations in pressure, flow rate, and overall system performance, resulting in reduced pumping efficiency. Secondly, a faulty accumulator can lead to increased wear and tear on the pump. When the accumulator fails to regulate the pressure properly, it can cause the pump to work harder and operate outside its normal operating range. This additional stress on the pump can lead to premature failure, decreased lifespan, and increased maintenance costs. Ultimately, this affects the pumping efficiency as the pump may not be able to deliver the desired flow rate and pressure due to its compromised condition. Furthermore, a faulty accumulator may result in unstable or inconsistent flow rates. As the accumulator is responsible for maintaining a steady flow of fluid, any malfunction can disrupt this flow pattern. This inconsistency in flow can lead to inefficiencies in the pumping system, such as increased energy consumption, reduced output, and inadequate operation of downstream components. Lastly, a faulty accumulator can impact the overall system response time. Accumulators play a crucial role in providing quick response and compensating for sudden changes in demand. If the accumulator fails to function properly, the system may experience delays in responding to load changes, leading to slower operation, reduced productivity, and potential safety hazards. In conclusion, a faulty accumulator can have a detrimental impact on pumping efficiency. It can cause imbalances in the hydraulic system, increase wear on the pump, result in unstable flow rates, and decrease overall system response time. Regular maintenance, inspection, and timely repair or replacement of faulty accumulators are essential to ensure optimal pumping efficiency and prevent potential system failures.

- Q: How often should hopper agitator shafts be inspected or replaced in a concrete pump?

- Hopper agitator shafts in a concrete pump should be regularly inspected and maintained to ensure optimal performance and prevent potential breakdowns. The frequency of inspection or replacement depends on several factors such as the usage and operating conditions of the pump. As a general guideline, it is recommended to inspect the hopper agitator shafts at least once every three to six months. During the inspection, the shafts should be checked for any signs of wear, damage, or misalignment. If any issues are detected, appropriate measures should be taken, such as lubrication, realignment, or replacement of damaged parts. However, it is important to note that the frequency of inspection may vary depending on the intensity of use, the type of materials being pumped, and the overall condition of the pump. For instance, if the pump is subjected to heavy-duty or continuous operation, it may be necessary to inspect the agitator shafts more frequently, such as on a monthly basis. Regular maintenance and inspection of hopper agitator shafts not only ensure the smooth operation of the concrete pump but also extend the lifespan of the equipment. Timely detection and resolution of any issues can prevent costly repairs or downtime in the future. Additionally, following the manufacturer's recommendations and guidelines for maintenance can help optimize the performance and reliability of the concrete pump.

- Q: How long do concrete pump rubber hoses typically last?

- Concrete pump rubber hoses typically last around 1 to 5 years, depending on various factors such as usage, maintenance, and environmental conditions.

- Q: What is the role of a concrete pump hopper grate pin retainer?

- The role of a concrete pump hopper grate pin retainer is to secure the grate pins in place, preventing them from dislodging or falling out during the pumping process. This helps to maintain the stability and integrity of the hopper grate, ensuring efficient and safe operation of the concrete pump.

- Q: How often should hopper agitator blades be inspected or replaced in a concrete pump?

- Hopper agitator blades in a concrete pump should be inspected regularly, ideally on a monthly basis, to ensure that they are functioning properly. Replacement of the blades should be done as necessary, depending on the wear and tear they have undergone.

Send your message to us

Concrete Pumping Sylinder (ZOOMLION ) I.D.:DN205 Length:2284MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords