PUMPING CYLINDER(ZOOMLION) I.D.:DN200 CR. THICKNESS :0.25MM-0.3MM LENGTH:2022MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

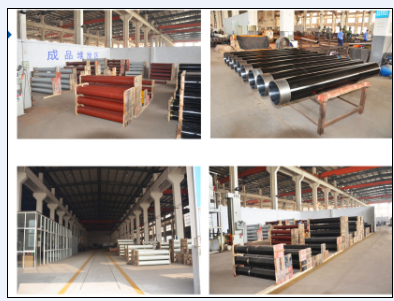

The Concrete Pump Delivery Cylinder DN200*2022 normally made by steel material No. C45. according to customer’s requests, and also package in bundles or nude packing directly put into container.

Scope of Application of the Cylinders

The Pump Delivery Cylinder DN200*2022 is a Cylinder pumping for combined use with other concrete pumps parts in concrete pumping operations. It can be widely used in the construction of various types of concrete structures like industrial and civil buildings, bridges, roads, and other types of infrastructure.

This Cylinder Cylinder DN200*2022 can only be used in concrete pump construction operations, but not in any other operations, like dragging, moving, or hoisting heavy articles or personnel. The pipe is also not allowed to be used in any location where any combustible or explosive material exists or a cave-in may occur.

Specifications:

Concrete Pump Delivery Cylinder DN200*2022

1. Capacity: 60,000~80,000cbm

2. Size: DN180, DN200, DN230.DN250

3. Material: C45

4. quenching and tempering to improve the hardness to HB241-280

5. inner wall chrome thickness is 0.25-0.30mm, hardness HV820-900.

6. Brand: SCHWING, PM, SANY, KYOKUTO, CIFA

7. Capacity: 60,000~80,000cbm

Product Advantages:

OKorder's Cylinders DN200*2022 Channels are durable, strong, and safety.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (10-20 days)

Reliable performance

Easy to weld

High safety.

· Professional Service

· Competitive pricing

Measuring of wall thickness from the outside

Low purchase cost

FAQ:

Q1: How long about delivery time about DN200*2022 ?

A1: Normally we keep the raw materials for old customers and sometime we also keep stock products to make sure delivery time in any emergency cases.

Q2: How do we guarantee the quality of our Cylinders DN200*2022?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will book the vessel for goods. The specific shipping date is dependent upon international and government factors, but is typically10 to 30 workdays.

Q4: If we can produce some Cylinders DN200*2022 according to customers request?

A4: Yes, we can produce Cylinders DN200*2022 according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world.

- Q: Can concrete pump spare parts be coated with anti-corrosion or anti-wear coatings?

- Certainly, it is possible to apply anti-corrosion or anti-wear coatings to concrete pump spare parts. These coatings serve as an extra protective layer, effectively shielding the spare parts from corrosion and wear caused by the tough operating conditions and abrasive substances encountered during concrete pumping. Usually composed of materials like epoxy, polyurethane, or ceramic, these coatings boast exceptional resistance against corrosion and wear. By applying these coatings, the lifespan of concrete pump spare parts can be significantly prolonged, consequently reducing the need for frequent replacements and resulting in cost savings for operators. Furthermore, the presence of anti-corrosion and anti-wear coatings can enhance the overall performance and efficiency of the concrete pump, ensuring smooth and dependable operation.

- Q: Which is the best home made concrete pump car?

- The second is heavy Futian Fortaleza, Xiangjian, Xugong, honedeli, the price is high, basically there is no big problem

- Q: How do I determine the correct temperature ratings for concrete pump spare parts?

- Determining the appropriate temperature ratings for spare parts of your concrete pump requires careful consideration of the specific requirements and specifications of your pump system. To assist you in this process, the following steps can be taken: 1. Review the manufacturer's documentation: Begin by examining the technical specifications provided by the manufacturer of your concrete pump system. The manufacturer should furnish temperature ratings for various components and spare parts. Look for information regarding temperature limits, recommended operating temperature ranges, as well as any specific guidelines or restrictions pertaining to temperature. 2. Identify crucial components: Identify the key components of your concrete pump system that may be impacted by temperature, such as hoses, seals, gaskets, valves, and electrical components. These components may possess different temperature ratings based on the materials used and their specific design. 3. Evaluate application conditions: Assess the operating conditions of your concrete pump system to determine the potential temperature extremes it may encounter. Factors such as ambient temperature, concrete mix temperature, and the presence of external heat sources (e.g., hot weather or neighboring equipment) can influence the temperature of the system and its spare parts. 4. Verify compatibility: Ensure that the spare parts you are considering are compatible with the specific temperature range of your concrete pump system. Some components may possess different ratings based on factors like chemical compatibility, thermal expansion, and resistance to heat transfer. 5. Seek professional advice: If you are uncertain about the temperature ratings or require further clarification, it is advisable to consult professionals or experts in the field of concrete pump systems. They can offer specific recommendations based on their knowledge and experience. By following these steps and considering the manufacturer's guidelines and expert advice, you can determine the appropriate temperature ratings for spare parts of your concrete pump, thus guaranteeing the safe and efficient operation of your system.

- Q: How do I properly maintain and replace hydraulic hoses in concrete pump spare parts?

- Proper maintenance and replacement of hydraulic hoses in concrete pump spare parts involve a few essential steps. Firstly, it is crucial to regularly inspect the hoses for signs of wear, including cracks, leaks, or bulges. Any damaged hoses should be replaced immediately to avoid any potential accidents or disruptions in the pumping process. When replacing hydraulic hoses, it is essential to use high-quality hoses that are compatible with the concrete pump system. It is recommended to consult the manufacturer's guidelines or seek professional advice to ensure the correct specifications and fittings are used. During installation, make sure to properly clean and prepare the hose fittings and connections. This involves removing any debris or dirt that could cause contamination or hinder a secure connection. Additionally, it is essential to follow the recommended torque specifications when tightening the fittings to prevent over-tightening or under-tightening, which can lead to leaks or hose failure. Regular maintenance also includes regularly checking and replacing hydraulic oil and filters according to the manufacturer's recommendations. This helps to ensure optimal performance and prolong the lifespan of the hydraulic hoses and other components. Overall, proper maintenance and replacement of hydraulic hoses in concrete pump spare parts require regular inspections, the use of high-quality hoses, proper cleaning and preparation during installation, correct torque specifications, and adherence to manufacturer guidelines for maintenance and replacement intervals.

- Q: How often should concrete pump control boxes be inspected and replaced?

- To maintain proper functioning and safety, it is essential to regularly inspect the control boxes of concrete pumps. The frequency of inspections and replacements will vary depending on factors such as pump usage, operating conditions, and manufacturer recommendations. In general, it is advisable to inspect the control box at least once a year or according to the manufacturer's guidelines. However, if the concrete pump is extensively used or exposed to harsh conditions, more frequent inspections may be needed. This involves checking electrical connections, switches, buttons, and indicators for signs of wear, damage, or malfunction. Moreover, inspections should be conducted after significant maintenance or repairs on the pump, as well as following any incidents or accidents. Regular inspections allow for early identification of potential issues, enabling timely repairs or replacements and reducing the risk of breakdowns or accidents. When it comes to replacements, control boxes should be replaced if they cannot be repaired or if they are outdated and no longer meet safety standards. It is important to consult the manufacturer or a qualified professional to determine the appropriate replacement schedule based on the specific conditions and usage of the concrete pump. Always remember, regular inspections and timely replacements of concrete pump control boxes are essential for ensuring the safe and efficient operation of the equipment.

- Q: How often should hydraulic accumulator bladders be inspected or replaced in a concrete pump?

- Hydraulic accumulator bladders in a concrete pump should be inspected regularly, ideally every 6-12 months, to ensure they are in good condition and functioning properly. However, the frequency of replacement depends on various factors such as the pump's usage, operating conditions, and manufacturer's recommendations. It is best to consult the concrete pump's manual or reach out to the manufacturer for specific guidance on when to replace the bladders.

- Q: How do I ensure the compatibility of mechanical components in concrete pump spare parts?

- To ensure the compatibility of mechanical components in concrete pump spare parts, it is crucial to consider several factors. First, it is important to identify the specific make and model of the concrete pump and its components. This information will help in sourcing the correct spare parts that are designed to fit and function properly with the existing system. Additionally, it is recommended to consult the manufacturer's documentation or reach out to their customer support for guidance. They can provide detailed specifications and compatibility guidelines for the mechanical components. It is essential to match the dimensions, tolerances, and materials of the spare parts to the original components to ensure a proper fit and optimal performance. Furthermore, working with reputable suppliers or distributors who specialize in concrete pump spare parts can greatly enhance compatibility assurance. These professionals have extensive knowledge and experience in the industry and can guide you in selecting the right components that are compatible with your specific concrete pump model. Regular maintenance and inspection of the mechanical components are also essential to identify any wear or damage. By addressing any issues promptly and replacing worn-out parts with compatible ones, you can ensure the overall compatibility and longevity of the mechanical components in your concrete pump spare parts.

- Q: What are some common issues with concrete pump pipes and how can they be prevented?

- Some common issues with concrete pump pipes include clogging, wear and tear, and leakage. These issues can be prevented by regularly cleaning the pipes to avoid clogging, using high-quality pipes that are resistant to wear and tear, and ensuring proper installation and maintenance to prevent leakage. Additionally, using the correct concrete mix and adjusting the pump pressure appropriately can also help prevent these issues.

- Q: What is the function of a concrete pump hopper grate handle?

- The function of a concrete pump hopper grate handle is to provide a means for operators to easily lift and remove the grate from the hopper, allowing for inspection, maintenance, or cleaning of the pump's interior.

- Q: What are the precautions for gas washing of concrete pump?

- During gas cleaning, the personnel shall not be close to the outlet of the discharge pipe, the pipe is turned sharply (if 90 bends) and the compressed air pipe is connected

Send your message to us

PUMPING CYLINDER(ZOOMLION) I.D.:DN200 CR. THICKNESS :0.25MM-0.3MM LENGTH:2022MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords