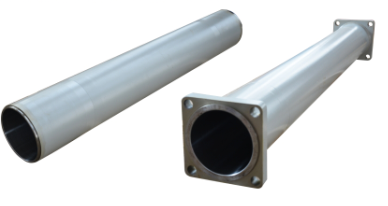

DELIVERY CYLINDER(ZOOMLION ) I.D.:DN200 CR. THICKNESS :0.25MM-0.3MM COLOR:WHITE LENGTH:1187MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Packaging & Delivery

| Packaging Detail: | wooden case, seaworthy packing |

| Delivery Detail: | 15 days |

Specifications

Concrete Pump Delivery Cylinder DN200*1187

1. Capacity: 60,000~80,000cbm

2. Size: DN180, DN200, DN230..

4. Brand: PM, Sany,ZM

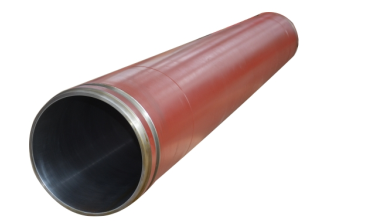

Concrete Pump Delivery Cylinder DN230*2100

1. Material: C45

2. quenching and tempering to improve the hardness to HB241-280

3. inner wall chrome thickness is 0.25-0.30mm, hardness HV820-900.

4. Brand: SCHWING, PM, SANY, KYOKUTO, CIFA

5. Capacity: 60,000~80,000cbm

- Q:What is the role of a concrete pump hopper grate pin retainer?

- The role of a concrete pump hopper grate pin retainer is to secure the grate pins in place, preventing them from dislodging or falling out during the pumping process. This helps to maintain the stability and integrity of the hopper grate, ensuring efficient and safe operation of the concrete pump.

- Q:How can a faulty oil cooler affect the pump's hydraulic system?

- The pump's hydraulic system can be affected in multiple ways by a defective oil cooler. Firstly, it is the responsibility of the oil cooler to maintain the hydraulic oil at an optimal temperature. If the oil cooler is flawed and fails to cool the oil efficiently, the hydraulic oil may become overheated. This can result in a decrease in the oil's viscosity, causing it to lose its lubricating properties. Consequently, the pump's moving parts may experience heightened friction and wear, leading to reduced efficiency and potential damage to the pump itself. Secondly, a defective oil cooler can lead to inadequate cooling of the hydraulic oil, resulting in elevated temperatures within the system. Elevated temperatures can cause the oil to oxidize, leading to the formation of sludge and varnish deposits. These deposits can obstruct the smooth operation of the hydraulic system, including the pump, valves, and other components, potentially causing malfunctions. Furthermore, a faulty oil cooler can also cause a decrease in the rate of oil flow. If the oil cooler is not functioning properly, it can restrict the flow of hydraulic oil, reducing the amount of oil available for the pump's operation. This can result in decreased hydraulic pressure, affecting the pump's performance and potentially causing issues such as reduced power output or inadequate operation of hydraulic actuators. In summary, a defective oil cooler can have negative effects on the pump's hydraulic system, including overheating, increased friction and wear, the formation of deposits, and a reduced oil flow rate. It is essential to regularly inspect and maintain the oil cooler to ensure proper functioning and prevent potential damage to the hydraulic system.

- Q:What are the different types of concrete pump hopper cylinders?

- There are several different types of concrete pump hopper cylinders that are commonly used in the construction industry. These cylinders play a crucial role in the operation of concrete pumps by providing the necessary pressure and force to move the concrete through the system. One type of concrete pump hopper cylinder is the single-acting cylinder. This type of cylinder operates by using hydraulic pressure to extend the piston rod, which in turn pushes the concrete out of the hopper and into the pumping system. Single-acting cylinders are known for their simplicity and reliability, making them a popular choice for many construction projects. Another type of concrete pump hopper cylinder is the double-acting cylinder. As the name suggests, this type of cylinder operates in both directions, allowing for a more efficient and powerful pumping process. Double-acting cylinders are capable of pushing the concrete out of the hopper during the extension stroke and pulling the piston rod back during the retraction stroke, resulting in a higher pumping capacity and increased productivity. Additionally, there are also different sizes and capacities of concrete pump hopper cylinders available, ranging from smaller cylinders suitable for smaller construction projects to larger cylinders capable of handling heavy-duty pumping operations. The choice of cylinder size depends on factors such as the volume of concrete to be pumped, the distance and height of the pumping location, and the specific requirements of the project. In conclusion, the different types of concrete pump hopper cylinders include single-acting cylinders and double-acting cylinders. Each type has its own advantages and is suitable for different construction applications. The size and capacity of the cylinder should be chosen based on the specific needs of the project. Ultimately, selecting the right type of cylinder is crucial for ensuring efficient and effective concrete pumping operations.

- Q:How often should hopper grate pin retainers be inspected or replaced in a concrete pump?

- Hopper grate pin retainers in a concrete pump should be inspected regularly, ideally on a monthly basis, to ensure their proper functioning and prevent any potential issues. However, the frequency of inspections may vary depending on the specific conditions of use and the manufacturer's recommendations. During these inspections, it is essential to check for any signs of wear, damage, or corrosion on the hopper grate pin retainers. If any of these issues are detected, immediate replacement is necessary to maintain the efficiency and safety of the concrete pump. Additionally, it is crucial to adhere to the manufacturer's guidelines regarding the lifespan of the hopper grate pin retainers. Some manufacturers may recommend replacing them after a certain number of operating hours, while others may suggest replacement based on the visual condition during inspections. Regular inspections and timely replacement of hopper grate pin retainers are crucial to prevent potential malfunctions or accidents during concrete pumping operations. It is always recommended to consult the concrete pump's manual or contact the manufacturer for specific guidelines regarding the inspection and replacement intervals for hopper grate pin retainers.

- Q:How often should concrete pump filters be inspected and replaced?

- Concrete pump filters should be inspected regularly, ideally on a weekly basis. The frequency of replacement will depend on various factors such as the type of pump, the quality of concrete being pumped, and the working conditions. Generally, filters should be replaced when they become clogged or when their efficiency is compromised. This may occur anywhere from every few weeks to a few months. It is crucial to maintain clean and functional filters to prevent blockages, enhance pump performance, and ensure the longevity of the equipment.

- Q:What are the different types of concrete pump hopper screens?

- There is a wide range of hopper screens available for concrete pumps, each designed to meet specific needs and requirements. 1. The wire mesh screen is the most commonly used type. It is made of woven wire mesh and prevents large debris or aggregates from entering the pump system. These screens come in various sizes and can be easily replaced when worn or damaged. 2. Perforated plate screens are made of solid metal plates with small holes or perforations. They are particularly effective in preventing fine particles or sediments from entering the pump system. Perforated plate screens are more durable than wire mesh screens and can withstand heavy-duty applications. 3. Polyurethane screens are made of polyurethane material, which has excellent resistance to abrasion and wear. These screens are commonly used in high-performance concrete pumps that handle abrasive materials. They are highly durable and can be easily cleaned or replaced when necessary. 4. Some concrete pump hoppers are equipped with a vibrating screen, which separates and removes solids or debris from the concrete mixture. The vibrating screen uses vibration to facilitate the separation process, ensuring a cleaner and more consistent concrete flow. 5. Self-cleaning screens are designed with a mechanism that prevents clogging and maintains an uninterrupted concrete flow. These screens, usually made of wire mesh or perforated plate, use mechanical or pneumatic methods to automatically remove debris from the screen surface. When selecting a hopper screen, it is crucial to consider the specific requirements of your concrete pumping operation. Factors such as aggregate size, presence of fine particles, and abrasiveness should be taken into account to ensure optimal performance and longevity.

- Q:How do I properly maintain and replace rubber pistons in concrete pump spare parts?

- Maintaining and replacing rubber pistons in concrete pump spare parts is crucial for the efficient operation of the pump and to ensure a longer lifespan of the equipment. Here are some steps to properly maintain and replace rubber pistons in concrete pump spare parts: 1. Regular Inspection: It is important to inspect the rubber pistons regularly to identify any signs of wear or damage. Look for cracks, tears, or any other visible signs of deterioration. 2. Cleaning: Before replacing the rubber pistons, make sure to thoroughly clean the area around the pistons. Remove any dirt, debris, or concrete residue that may be present. This will help prevent contamination and ensure a proper fit for the new pistons. 3. Proper Lubrication: Apply a suitable lubricant to the rubber pistons to ensure smooth operation and reduce friction. This will help prolong the life of the pistons and prevent premature wear. 4. Correct Installation: When replacing the rubber pistons, ensure they are properly installed according to the manufacturer's instructions. Use the correct tools and techniques to avoid damaging the pistons or other components of the pump. 5. Quality Replacement Parts: Always use high-quality replacement rubber pistons from reputable suppliers. Inferior quality pistons may not perform as well and could result in frequent replacements or damage to the pump. 6. Regular Maintenance: Implement a regular maintenance schedule for your concrete pump, including the rubber pistons. This can include cleaning, lubrication, and inspection of the pistons to identify any signs of wear or damage before they become major issues. 7. Training and Expertise: Ensure that the person responsible for maintaining and replacing the rubber pistons has the necessary training and expertise. This will help ensure the job is done correctly and minimize the risk of damage to the pump or injury to personnel. By following these steps, you can properly maintain and replace rubber pistons in concrete pump spare parts, ensuring optimal performance and longevity of the equipment.

- Q:How do I properly maintain and replace hydraulic pumps in concrete pump spare parts?

- To ensure the smooth functioning and long life of your equipment, it is crucial to properly maintain and replace hydraulic pumps in concrete pump spare parts. Here are some steps that can assist you in this process: 1. Conduct Regular Inspections: Before and after each use, visually inspect the hydraulic pump to detect any signs of wear, leaks, or damage. Additionally, check for loose bolts, damaged seals, or excessive noise during operation. 2. Adhere to Manufacturer's Guidelines: Consult the manufacturer's guidelines and recommendations regarding the maintenance and replacement of hydraulic pumps. They will provide specific instructions concerning the frequency of maintenance, lubrication, and replacement intervals. 3. Ensure Proper Lubrication: Smooth operation of hydraulic pumps requires proper lubrication. Regularly check the oil levels and refill if necessary. Utilize the recommended oil or hydraulic fluid as specified by the manufacturer. Adhere to the guidelines regarding the frequency of oil changes. 4. Maintain Regular Cleaning: Keep the hydraulic pump and its components free from debris, dust, and dirt. Employ a clean cloth or compressed air to eliminate any accumulated contaminants. This practice will help prevent damage and minimize the likelihood of clogs or blockages. 5. Replace Worn Parts: Over time, certain components of the hydraulic pump may wear out and necessitate replacement. Maintain a stock of spare parts, including seals, gaskets, and filters, to promptly replace any worn or damaged components. 6. Seek Professional Assistance: If you are uncertain about any aspect of maintaining or replacing hydraulic pumps, it is advisable to consult a professional technician or the manufacturer. They possess the expertise and knowledge to guide you through the process and ensure the best maintenance and replacement practices. Remember, regular maintenance and timely replacement of hydraulic pumps in concrete pump spare parts will not only prolong the lifespan of your equipment but also ensure safe and efficient operation on construction sites.

- Q:How can the concrete pump pipe be cleaned?

- When the concrete in the pipeline has all been emptied and the sponge ball has been fired, the air washing is completed. At this time, the compressed air intake valve should be closed, and then remove all kinds of pipe fittings.

- Q:How much do concrete pump spare parts typically cost?

- The cost of concrete pump spare parts can vary significantly depending on the specific part needed, its brand, quality, and availability. It is recommended to contact suppliers or manufacturers for accurate and up-to-date pricing information.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

DELIVERY CYLINDER(ZOOMLION ) I.D.:DN200 CR. THICKNESS :0.25MM-0.3MM COLOR:WHITE LENGTH:1187MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords