Concrete Pumping Cylinder Model (PM) I.D.:DN230 X 2100MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

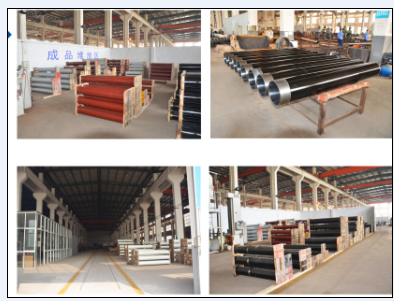

The Concrete Pumping Cylinder Model (PM) I.D.:DN230 X 2100MM normally made by steel material No. C45. according to customer’s requests, and also package in bundles or nude packing directly put into container.

Scope of Application of the Cylinders

The Concrete Pumping Cylinder Model (PM) I.D.:DN230 X 2100MM is a concrete pumping for combined use with other concrete pumps in concrete pumping operations. It can be widely used in the construction of various types of concrete structures like industrial and civil buildings, bridges, roads, and other types of infrastructure.

This Concrete Pumping Cylinder Model (PM) I.D.:DN230 X 2100MM can only be used in concrete pump construction operations, but not in any other operations, like dragging, moving, or hoisting heavy articles or personnel. The pipe is also not allowed to be used in any location where any combustible or explosive material exists or a cave-in may occur.

Specifications:

Concrete Pumping Cylinder Model (PM) I.D.:DN230 X 2100MM

1. Life Span: 60,000~80,000cbm

2. Size: DN180, DN200, DN230..

4. Brand: PM

5. Material: Steel C45

6. Quenching and tempering to improve the hardness to HB241-280

7. Inner wall chrome thickness is 0.25-0.30mm, hardness HV820-900.

Product Advantages:

OKorder'sConcrete Pumping Cylinder Model (PM) I.D.:DN230 X 2100MM Channels are durable, strong, and safety.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (10-20 days)

Reliable performance

Easy to weld

High safety.

· Professional Service

· Competitive pricing

Measuring of wall thickness from the outside

Low purchase cost

FAQ:

Q1: How long about delivery time about DN230*2100?

A1: Normally we keep the raw materials for old customers and sometime we also keep stock products to make sure delivery time in any emergency cases.

Q2: How do we guarantee the quality of our Cylinders DN230*2100?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will book the vessel for goods. The specific shipping date is dependent upon international and government factors, but is typically10 to 30 workdays.

Q4: If we can produce some Cylinders according to customers request?

A4: Yes, we can produce Cylinders according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, If needed,

- Q: Are there any safety considerations when using concrete pump spare parts?

- Yes, there are several safety considerations when using concrete pump spare parts. Firstly, it is important to ensure that the spare parts are of high quality and meet the necessary safety standards. Using substandard or faulty spare parts can increase the risk of accidents and malfunctions. Additionally, proper training and knowledge of the equipment and spare parts are crucial to ensure safe operation. Regular inspection and maintenance of the spare parts are also essential to prevent any potential hazards. Lastly, following all safety guidelines and protocols provided by the manufacturer is necessary to minimize the risk of injuries or accidents while using concrete pump spare parts.

- Q: Are there any specific guidelines for the selection and installation of hydraulic components in concrete pump spare parts?

- Yes, there are specific guidelines for the selection and installation of hydraulic components in concrete pump spare parts. It is crucial to consider factors such as the pump's maximum pressure and flow rate, compatibility of components with the pump's system, and the quality and reliability of the components. Additionally, proper installation techniques and following manufacturer recommendations are essential to ensure optimal performance and longevity of the hydraulic system in concrete pump spare parts.

- Q: How can a faulty gearbox affect the pump's performance?

- The performance of a pump can be significantly affected by a faulty gearbox, which is responsible for transmitting power from the motor to the pump. Any dysfunction in this component can result in various issues. To begin with, a decrease in the pump's efficiency can be caused by a faulty gearbox. Its purpose is to regulate the speed and torque of the pump, ensuring optimal operation. If the gearbox is faulty, it may not be able to provide sufficient power to the pump, leading to reduced performance and efficiency. This can result in increased energy consumption and decreased overall productivity. Moreover, excessive vibration and noise can be experienced by the pump due to a faulty gearbox. A properly functioning gearbox helps absorb and distribute the forces generated during operation, minimizing vibration and noise levels. However, if the gearbox is faulty, it may fail to adequately dampen these forces, resulting in heightened vibrations and noise. This can not only affect the pump's performance but also cause premature wear and tear of other components, further impacting its efficiency. Furthermore, inconsistent flow rates and pressure fluctuations can be caused by a faulty gearbox. The gearbox plays a crucial role in controlling the speed and output of the pump. If it is malfunctioning, it may be unable to maintain a consistent flow rate or pressure, leading to fluctuations in the pump's performance. Inconsistent flow rates can disrupt processes that rely on precise volumes or pressures, causing inefficiencies and potential damage to downstream equipment. In conclusion, the performance of a pump can be detrimentally affected by a faulty gearbox. It can lead to decreased efficiency, increased vibrations and noise, as well as inconsistent flow rates and pressure fluctuations. Therefore, it is crucial to regularly maintain and promptly repair or replace faulty gearboxes to ensure the optimal functioning of pumps and prevent any further damage or operational issues.

- Q: What is the farthest pumping distance of concrete pump truck?

- Now the domestic pump to achieve the highest pump height, the largest is ZOOMLION made 80 m carbon fiber boom pump, but also to achieve the pump Guinness world record

- Q: Are there any specific guidelines for the installation of seal kits or O-rings in concrete pump spare parts?

- Concrete pump spare parts have specific guidelines for the installation of seal kits or O-rings. Here are some general guidelines you should follow: 1. Prioritize safety: Before attempting installation, make sure the concrete pump is turned off and depressurized. Protect yourself by wearing appropriate safety gear like gloves and goggles. 2. Prepare the area: Thoroughly clean the installation area to ensure a smooth and debris-free surface for the seal kits or O-rings. 3. Inspect the parts: Before installation, carefully examine the seal kits or O-rings for any defects or damage. Replace any faulty parts with new ones. 4. Apply lubrication: To facilitate installation and prevent damage, use a small amount of compatible lubricant or hydraulic oil on the seal kits or O-rings. Ensure the lubricant is suitable for the materials used. 5. Align correctly: Align the seal kits or O-rings with their respective grooves or seating areas in the concrete pump. Make sure they are properly seated and positioned. 6. Install properly: Use the appropriate tools and techniques to install the seal kits or O-rings. Avoid applying excessive force or bending, as this can cause damage or improper sealing. 7. Test for functionality: After installation, test the concrete pump to ensure the seal kits or O-rings are functioning properly. Check for leaks or any abnormal behavior during operation. 8. Maintain regularly: Regular inspection and maintenance are crucial for the longevity and optimal performance of the seal kits or O-rings. Follow the manufacturer's recommended maintenance schedule and guidelines. It's important to note that these guidelines are general and may vary depending on the specific make and model of the concrete pump. Always consult the manufacturer's instructions and guidelines for the particular seal kits or O-rings being installed.

- Q: What are the different types of concrete pump hydraulic pumps?

- There are several different types of hydraulic pumps that are commonly used in concrete pumps. 1. Gear pumps: Gear pumps are one of the most common types of hydraulic pumps used in concrete pumps. They consist of two meshing gears that push the hydraulic fluid from the inlet to the outlet. Gear pumps are known for their simplicity, durability, and reliability. 2. Piston pumps: Piston pumps are another popular type of hydraulic pump used in concrete pumps. They use reciprocating pistons to move the hydraulic fluid. Piston pumps are known for their high pressure capabilities and ability to handle heavy-duty applications. 3. Vane pumps: Vane pumps are often used in smaller concrete pumps or as auxiliary pumps in larger pumps. They use a series of vanes that rotate inside a housing to move the hydraulic fluid. Vane pumps are known for their compact size and efficiency. 4. Radial piston pumps: Radial piston pumps are typically used in high-pressure concrete pumps. They have multiple pistons arranged radially around a central shaft. The pistons move in and out to create the pumping action. Radial piston pumps are known for their high efficiency and power. 5. Axial piston pumps: Axial piston pumps are commonly used in large concrete pumps. They have multiple pistons arranged in a circular pattern around a central shaft. The pistons move in a linear motion to create the pumping action. Axial piston pumps are known for their high flow rates and pressure capabilities. Overall, the choice of hydraulic pump for a concrete pump depends on various factors such as the size of the pump, the desired pressure and flow rate, and the specific application requirements.

- Q: How often should concrete pump remote control antennas be inspected and replaced?

- Concrete pump remote control antennas should be inspected regularly to ensure they are in good working condition. The frequency of inspections will depend on the usage and working conditions of the concrete pump. In general, it is recommended to inspect the antennas at least once a year or after every 500 hours of usage, whichever comes first. However, if the pump is used in harsh environments or experiences frequent wear and tear, more frequent inspections may be necessary. It is important to check for any signs of damage, such as cracks, corrosion, or loose connections. If any damage is detected, the antenna should be replaced immediately to prevent any disruptions in the remote control signal. Regular inspections and timely replacement of antennas will help ensure the smooth and efficient operation of the concrete pump.

- Q: Can I get spare parts for concrete pumps with different types of valve systems, such as S-valve or gate valve?

- Indeed, procuring spare parts for concrete pumps equipped with various valve systems, such as S-valve or gate valve, is entirely feasible. Manufacturers and suppliers of concrete pumps generally offer an extensive selection of spare parts, which encompass valves. These spare parts can be procured either directly from the manufacturer or via authorized distributors. To ensure compatibility, it is vital to furnish precise information regarding the concrete pump model, valve type, and any other pertinent details when placing an order for spare parts. Moreover, there exist specialized firms that exclusively concentrate on providing spare parts for concrete pumps, irrespective of the valve system employed. These entities often possess a comprehensive inventory of spare parts and can offer assistance in identifying and sourcing the necessary components for your specific concrete pump.

- Q: How does the concrete pump work?

- After position, the pump shall show stop light to avoid collision

- Q: What are the signs of a worn-out concrete pump piston?

- Some signs of a worn-out concrete pump piston may include decreased pumping efficiency, loss of pressure, increased noise or vibrations during operation, inconsistent concrete flow, and visible wear or damage on the piston surface.

Send your message to us

Concrete Pumping Cylinder Model (PM) I.D.:DN230 X 2100MM

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords