Concrete Pump Truck Parts Elbow Bend DN100 R170 90DGR 127MM Mn13-4 Casting

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 105 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Widely used on concrete pump truck, concrete placing boom, trailer concrete pump etc, for concrete delivery pipe connection.

Our concrete pump bends have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc

Main Product Features:

1. High Chromium and manganese content, which enables a higher wear resisting ability and longer lifetime.

2. The experiment done abroad shows that the life of our concrete pump elbow can reach 35000-150000cbm,got the customers' praise.

3. Possess quality certification of ISO 9001:2000. Can pass CE test.

4. We have been providing parts for nearly ten years, and cooperting with the agent of the world famous brand, possess near every kind of elbow in the market.

5. We can supply OEM service and can also produce according to your requirements.

6. Total series of concrete pump ELBOW for different brand concrete pump(PUTZMEISTER, SCHWING, CIFA, SANY, ZOOMLION, IHI, KYOKUTO Etc) available from us.

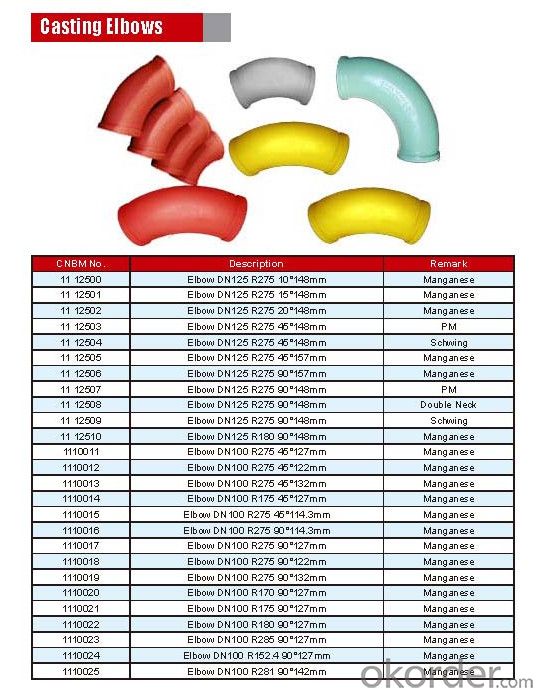

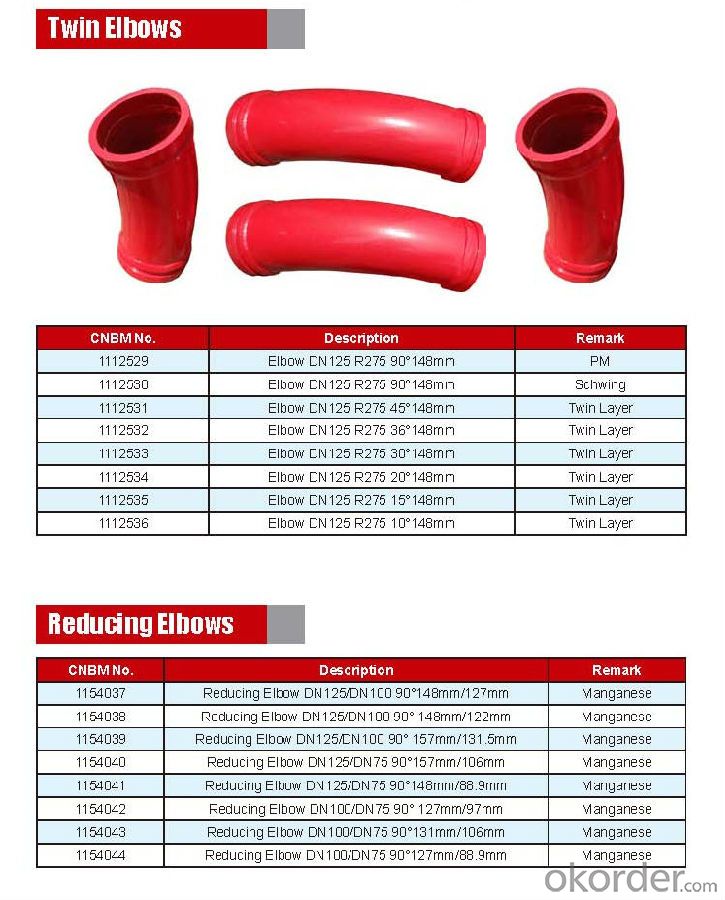

Product Specifications:

Technology: Cast

Dimension: DN100

Flange: 127mm

Radius: 170mm

Degree: 90D

Material: Mn13-4

Characteristics: According to our technology, the cast elbow also has high working pressure and burst pressure.

Package: Put in one seaworthy wooden box, and 20 boxes in one 20feet container.

FAQ:

Q1: How to confirm that your elbows could be used in our pump?

A1: We have been providing parts for more than ten years, and cooperting with the agent of the world famous brand, possess near every kind of elbow in the market. What is more, we can produce as the customers request with drawing provided.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 20 workdays.

Q4: If we can produce some Concrete Pump Truck Parts according to customers request?

A4: Yes, we can produce Concrete Pump Truck Parts according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

- Q: What are the skills of concrete pump?

- The floor of the concrete pump should be flat and solid; the whole machine should be placed horizontally and should not be tilted during the work

- Q: What are the indications of a damaged concrete pump boom?

- There are several indications that can point to a damaged concrete pump boom. These indications can include: 1. Visual damage: One of the most obvious signs of a damaged concrete pump boom is visible physical damage. This can include cracks, dents, or deformities in the boom structure. Any signs of structural damage should be taken seriously as they can compromise the integrity of the boom. 2. Leaks: Another indication of a damaged boom is the presence of leaks. If you notice hydraulic fluid or water leaking from the boom, it could be a sign of a damaged hose or fitting. Leaks can not only affect the performance of the pump but also pose a safety risk to the operator and those working around the equipment. 3. Misalignment: A damaged boom may also exhibit misalignment issues. If the boom is not straight or appears to be bent at an odd angle, it could indicate damage. Misalignment can affect the accuracy and efficiency of concrete placement, potentially leading to uneven or improper pouring. 4. Unusual noises: Strange or excessive noises during operation can be a sign of a damaged boom. Rattling, grinding, or squealing sounds can indicate loose or worn-out components, such as pins, bushings, or bearings. These noises should not be ignored, as they could worsen if not addressed promptly. 5. Reduced performance: A damaged boom may also result in reduced performance. If you notice a decrease in pumping capacity or difficulties in controlling the boom's movement, it could be an indication of damage. Poor performance can be caused by various issues, including hydraulic system problems, structural damage, or worn-out parts. In conclusion, it is crucial to regularly inspect and maintain concrete pump booms to identify any indications of damage. Promptly addressing these issues is essential to ensure the safety of operators, prevent further damage, and maintain the efficiency and performance of the equipment.

- Q: How often should concrete pump gearboxes be inspected and maintained?

- Concrete pump gearboxes should be inspected and maintained at regular intervals, typically every 6 to 12 months. However, the frequency may vary depending on the specific operating conditions and usage of the concrete pump. It is important to follow the manufacturer's recommendations and guidelines for maintenance to ensure optimal performance and longevity of the gearboxes.

- Q: What are the indications of a worn-out concrete pump clamp?

- A worn-out concrete pump clamp may exhibit several indications that replacement is necessary. These indications commonly include: 1. Leakage: In the event of leakage around the clamp area while operating the concrete pump, it could signify a worn-out clamp. This leakage may be a result of a faulty seal or gasket, which can no longer establish a secure and tight connection between the pump and the hose. 2. Vibrations and rattling: Excessive vibrations and rattling during the pumping process can be attributed to a worn-out clamp. This can occur when the clamp fails to firmly hold the hose in place, resulting in movement and instability. 3. Difficulty in tightening: If you encounter increasing difficulty in properly tightening the clamp, it may indicate wear-out. Over time, the components of the clamp may deteriorate, making it more challenging to achieve a secure and tight connection. 4. Visual damage: Inspect the clamp for visible signs of damage, such as cracks, dents, or corrosion. These physical damages can compromise the clamp's functionality, potentially leading to leaks or instability. 5. Excessive wear and tear: If you have been utilizing the same concrete pump clamp for an extended period without replacement, it is advisable to regularly inspect it for signs of excessive wear and tear. This may include worn-out or missing bolts, a deformed clamp body, or any other visible signs of deterioration. Promptly addressing any indications of a worn-out concrete pump clamp is crucial to ensure the safety and efficiency of pumping operations. If any of these signs are observed, it is recommended to seek professional consultation or replace the clamp to prevent potential accidents or disruptions in the concrete pumping process.

- Q: How do I properly maintain and replace filters in concrete pump spare parts?

- Proper maintenance and replacement of filters in concrete pump spare parts is crucial for ensuring the smooth and efficient operation of the equipment. Here are a few steps to follow: 1. Regular Inspection: Regularly inspect the filters for any signs of wear, clogs, or damage. Clean or replace them as necessary to maintain optimal performance. 2. Cleaning: If the filters are reusable, clean them according to the manufacturer's instructions. Use compressed air or a mild detergent solution to remove dirt, debris, and clogs. Ensure the filters are completely dry before reinstalling them. 3. Filter Replacement: If the filters are disposable or damaged beyond repair, replace them with suitable replacements recommended by the manufacturer. Ensure that the new filters are of the correct size and specifications. 4. Replacement Schedule: Follow the recommended replacement schedule provided by the manufacturer. Filters may need to be replaced based on usage hours, operating conditions, or as part of routine maintenance. Adhering to this schedule will help prevent premature wear and maintain the efficiency of the concrete pump. 5. Proper Installation: When replacing filters, ensure they are installed correctly, following the manufacturer's instructions. Improper installation can lead to leaks, reduced performance, or damage to the concrete pump. 6. Record Keeping: Maintain a record of filter replacements, cleaning, and maintenance activities. This will help track the lifespan of filters, anticipate replacement needs, and ensure timely maintenance. By following these steps, you can ensure that the filters in your concrete pump spare parts are properly maintained and replaced, promoting the longevity and efficiency of the equipment.

- Q: What are the causes of pipe blockage in concrete pump?

- Therefore, in the JGJ/T10-95 "concrete pumping construction technical regulations," stipulated that the sand through the 0.315mm sieve shall not be less than 15%.

- Q: What is the purpose of a concrete pump hopper grate?

- The main purpose of a concrete pump hopper grate is to safeguard the pump from any harm or obstruction that may be caused by large debris or foreign objects. Acting as a filter, this grate permits the passage of smaller particles and liquid concrete, while blocking bigger materials like rocks, wood, or other debris. By doing so, it ensures the pump's efficiency and functionality, guaranteeing a steady and uninterrupted flow of concrete. Moreover, the grate also provides protection for the pump's internal components, such as the impeller and valves, by preventing potential damage from larger objects. In summary, the concrete pump hopper grate holds immense significance in preserving the quality and dependability of the pumping process, effectively averting potential issues and ensuring the successful placement of concrete.

- Q: How can a malfunctioning control lever affect the pump's operation?

- The pump's operation can be significantly affected in several ways by a control lever that is malfunctioning. To begin with, the control lever is responsible for regulating the flow rate and pressure of the pump. If it is not functioning properly, it may be unable to accurately adjust these parameters, resulting in the pump not working correctly. Additionally, the ability of a malfunctioning control lever to effectively turn the pump on or off may be compromised. This can lead to the pump running continuously, even when it is unnecessary, causing unnecessary wear and tear on the pump and increased energy consumption. Furthermore, the control lever is often used to control the direction of flow in the pump. If it is not functioning correctly, it may be unable to switch the pump between forward and reverse modes, impacting the pump's efficiency in performing its intended tasks. Moreover, the overall safety of the pump operation can be affected by a malfunctioning control lever. If the lever fails to respond or becomes stuck in a position, it can potentially result in over-pressurization, leaks, or other hazardous situations, putting both the pump and surrounding equipment or personnel at risk. In conclusion, a control lever that is malfunctioning can disrupt the accurate regulation of flow rate, pressure, and direction of flow in the pump, potentially leading to improper functioning, increased energy consumption, reduced efficiency, and safety hazards. Therefore, it is crucial to promptly address any issues with the control lever to ensure the reliable operation of the pump.

- Q: How long do rubber pistons typically last in a concrete pump?

- The durability of rubber pistons in a concrete pump can differ based on various factors, including the rubber quality, frequency of use, concrete type, and maintenance practices. On average, rubber pistons in a concrete pump typically endure for approximately 500 to 1,500 hours of operation. Nevertheless, certain top-notch rubber pistons have been reported to last even longer when given appropriate care and maintenance. To prolong the lifespan of rubber pistons in a concrete pump, it is essential to regularly inspect, lubricate, and replace worn-out components. It is worth noting that these estimations serve as general guidelines, and the actual lifespan may vary in specific instances.

- Q: Can I get spare parts for concrete pump accessories like remote control systems?

- Yes, you can get spare parts for concrete pump accessories like remote control systems. Many manufacturers and suppliers of concrete pump accessories offer a range of spare parts for their products. These spare parts may include components for remote control systems such as buttons, switches, sensors, batteries, and transmitters. It is advisable to contact the manufacturer or supplier directly to inquire about the availability of spare parts for the specific model of remote control system you have. They will be able to provide you with the necessary information and assist you in obtaining the required spare parts.

Send your message to us

Concrete Pump Truck Parts Elbow Bend DN100 R170 90DGR 127MM Mn13-4 Casting

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 105 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords