Concrete Pump Truck Parts Elbow Bend DN100 R275 90DGR 148MM Mn13-4 Casting

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 140 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Widely used on concrete pump truck, concrete placing boom, trailer concrete pump etc, for concrete delivery pipe connection.

Our concrete pump bends have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc

Main Product Features:

1. Adopt the new plasma quenching and chromium plating process, which increases the concrete conveying life and reduces the frequency of replacement, saving the cost for the customers.

2. Service life: 55000-150000 CBM Concrete. The inner side of this concrete pump elbow undergoes heat treatment, and then the hardness can reach 68HRC.

3. Possess quality certification of ISO 9001:2000. Can pass CE test.

4. We have been providing parts for nearly ten years, and cooperting with the agent of the world famous brand, possess near every kind of elbow in the market.

5. We can supply OEM service and can also produce according to your requirements.

6. Total series of concrete pump ELBOW for different brand concrete pump(PUTZMEISTER, SCHWING, CIFA, SANY, ZOOMLION, IHI, KYOKUTO Etc) available from us.

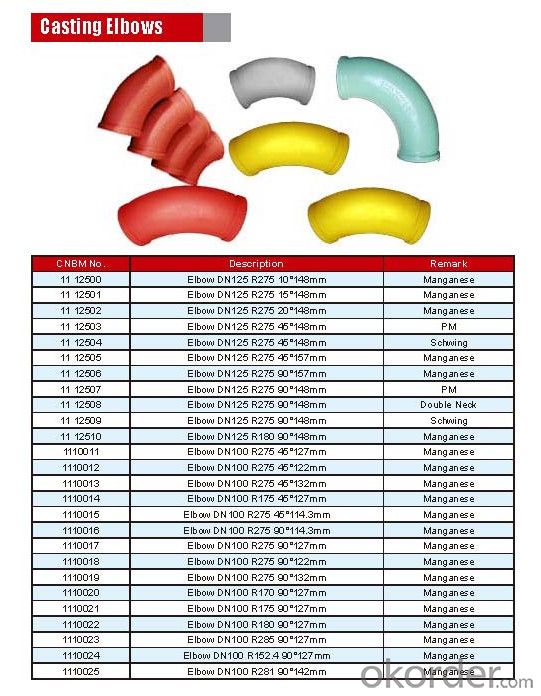

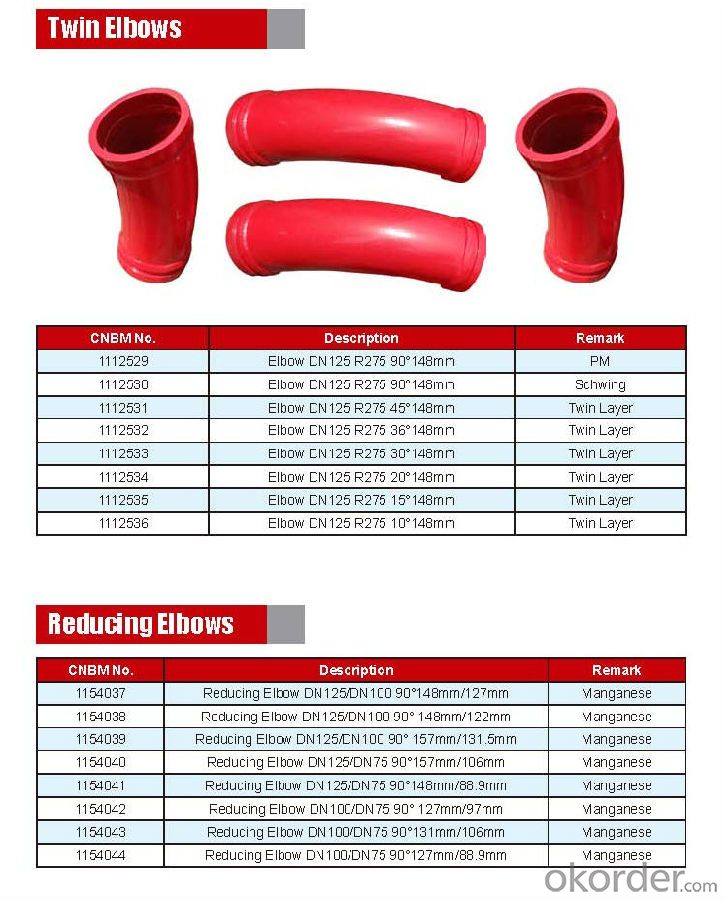

Product Specifications:

Technology: Cast

Dimension: DN100

Radius: 275mm

Degree: 45D

Material: Mn13-4

Weight: 6kg

Characteristics: According to our technology, the cast elbow also has high working pressure and burst pressure.

Package: Every 140pcs put in one seaworthy wooden box, and 20 boxes in one 20feet container.

FAQ:

Q1: How to confirm that your elbows could be used in our pump?

A1: We have been providing parts for nearly ten years, and cooperting with the agent of the world famous brand, possess near every kind of elbow in the market. What is more, we can produce as the customers request with drawing provided.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 20 workdays.

Q4: If we can produce some Concrete Pump Truck Parts according to customers request?

A4: Yes, we can produce Concrete Pump Truck Parts according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

- Q: What is the role of a concrete pump cylinder in a pumping system?

- The primary function of a concrete pump cylinder in a pumping system is to create the essential pressure and force needed for the transportation of concrete. This is achieved by the cylinder's ability to generate a reciprocating motion that propels the concrete through the pipeline. Typically, the concrete pump cylinder is connected to a piston which moves back and forth within the cylinder to facilitate the pumping action. As the piston moves towards the outlet end of the cylinder, it creates a vacuum that draws the concrete from the hopper. Conversely, when the piston moves in the opposite direction, it compresses the concrete, pushing it through the outlet valve, into the pipeline, and ultimately to the desired location. The size and design of the concrete pump cylinder are determined by various factors, including the desired pumping capacity, the distance over which the concrete needs to be transported, and the viscosity of the concrete mix. It is crucial for the cylinder to possess strength and durability to withstand the high pressures and repetitive movements involved in the pumping process. In conclusion, the concrete pump cylinder assumes the vital role of generating the necessary pressure and force for the efficient and effective transportation of concrete. It serves as the foundation of the pumping system, enabling a seamless and uninterrupted flow of concrete from the hopper to the desired destination.

- Q: How often do I need to replace concrete pump spare parts?

- The frequency at which you need to replace concrete pump spare parts depends on various factors such as the quality of the parts, the usage intensity of the pump, and the maintenance practices followed. Generally, high-quality concrete pump spare parts can last for a longer time and may not require frequent replacements. However, if the pump is used extensively or in demanding conditions, the spare parts may wear out more quickly. To ensure the optimal performance and longevity of the concrete pump, it is essential to adhere to a regular maintenance schedule. This includes inspecting the spare parts for any signs of wear and tear, monitoring their performance, and replacing them as needed. It is advisable to consult the manufacturer's guidelines or seek professional advice to determine the specific replacement intervals for your concrete pump's spare parts. Keep in mind that neglecting proper maintenance or using low-quality spare parts can lead to more frequent replacements, which can be costly and disrupt your construction projects. Therefore, investing in high-quality spare parts and following a diligent maintenance routine will help maximize the lifespan of your concrete pump and minimize the frequency of replacements.

- Q: What are the common signs of wear and tear on concrete pump spare parts?

- The common signs of wear and tear on concrete pump spare parts include cracks or fractures in the components, corrosion or rust on metal parts, excessive vibration or noise during operation, decreased performance or efficiency, and visible signs of wear on seals or gaskets.

- Q: What are the types, classifications and specifications of concrete pump?

- According to the ability of mixing materials, select the range of output; according to the aggregate of pumping concrete, select the form of the distribution valve

- Q: How often should hopper grate pin retainers be inspected or replaced in a concrete pump?

- To ensure proper functioning and prevent potential issues, it is important to regularly inspect hopper grate pin retainers in a concrete pump. Ideally, these inspections should be conducted on a monthly basis. However, the frequency of inspections may vary depending on usage conditions and manufacturer recommendations. During these inspections, it is essential to carefully examine the hopper grate pin retainers for any signs of wear, damage, or corrosion. If any of these issues are detected, immediate replacement is necessary to maintain the concrete pump's efficiency and safety. Furthermore, it is crucial to follow the manufacturer's guidelines regarding the lifespan of the hopper grate pin retainers. Some manufacturers may advise replacing them after a certain number of operating hours, while others may suggest replacement based on the condition observed during inspections. Regular inspections and timely replacement of hopper grate pin retainers play a crucial role in preventing malfunctions or accidents during concrete pumping operations. It is highly recommended to consult the concrete pump's manual or contact the manufacturer for specific guidelines on inspection and replacement intervals for hopper grate pin retainers.

- Q: How often should concrete pump clamps be inspected and replaced?

- Concrete pump clamps should be inspected regularly, ideally before each use, to ensure they are in proper working condition. Depending on the frequency of usage and the operating conditions, replacement of clamps may be needed every few months or after a certain number of pumping hours. It is important to consult the manufacturer's guidelines and seek professional advice to determine the specific inspection and replacement schedule for concrete pump clamps.

- Q: How do I properly maintain and replace rubber pistons in concrete pump spare parts?

- Proper maintenance and replacement of rubber pistons in concrete pump spare parts involves a few key steps. Firstly, make sure to regularly inspect the pistons for any signs of wear, such as cracks or tears. It is recommended to replace them if they are significantly worn or damaged. To replace the rubber pistons, start by removing the old piston carefully, ensuring not to damage the cylinder or any other components. Clean the cylinder thoroughly, removing any debris or residue. Apply a lubricant or concrete pump primer to the cylinder walls to aid in the installation of the new piston. Next, carefully install the new rubber piston, ensuring it is properly aligned with the cylinder. Gently push it into place, avoiding any unnecessary force that could cause damage. It is important to refer to the manufacturer's instructions or guidelines for specific installation techniques. After replacing the rubber piston, run a few tests to ensure its proper functioning. Check for proper sealing and smooth operation by conducting a dry run or pumping a small amount of concrete. Monitor the piston's performance closely, and if any issues arise, consult a professional or the manufacturer for further guidance. Regular maintenance, such as cleaning the cylinder and lubricating the pistons, can help extend their lifespan. Additionally, following proper operating procedures, such as avoiding excessive pressure or abrasive materials, can also contribute to the longevity of rubber pistons.

- Q: Are there any specific safety precautions while replacing concrete pump spare parts?

- There exists a variety of safety precautions that must be followed when replacing concrete pump spare parts. 1. Personal Protective Equipment (PPE) is of utmost importance and should be worn to safeguard against potential hazards. This includes safety goggles, gloves, a helmet, and steel-toed boots. 2. It is essential to adhere to proper lockout/tagout procedures prior to replacing any spare parts. This entails disconnecting and securing the power source to prevent accidental startup of the pump. 3. Before commencing the replacement process, inspect all tools and equipment for any indications of damage or defects. It is crucial to refrain from using faulty equipment, as it can pose significant safety risks. 4. When handling heavy spare parts, it is imperative to employ appropriate lifting techniques to prevent strain or injury. Ensure that proper assistance and equipment, such as cranes or forklifts, are available if necessary. 5. Maintain a clean and well-organized work area to prevent trips, slips, and falls. Remove any obstacles or debris that may jeopardize safety during the replacement process. 6. Only trained and authorized personnel should be involved in the replacement of concrete pump spare parts. They must possess a thorough understanding of the equipment and procedures to minimize the likelihood of accidents. 7. Always consult the manufacturer's guidelines and instructions when replacing spare parts. This will ensure that the process is executed safely and accurately. 8. It is vital to have a plan in place for potential emergencies, including fires or injuries. Make certain that fire extinguishers and first aid kits are easily accessible, and that all workers are familiar with their locations and usage. By adhering to these safety precautions, the risk of accidents, injuries, and damage can be significantly reduced when replacing concrete pump spare parts.

- Q: What is the role of a concrete pump hopper grate pin retainer?

- A concrete pump hopper grate pin retainer plays a crucial role in ensuring the safety and functionality of a concrete pump. It is responsible for securing the grate pins in place, which in turn helps to hold the hopper grate firmly in position. The hopper grate is an important component of a concrete pump as it acts as a barrier, preventing any debris or foreign objects from entering the hopper and potentially causing damage to the pump or interfering with the concrete mixing process. The grate pins, located on the sides of the hopper, help to keep the grate securely in place. The concrete pump hopper grate pin retainer is specifically designed to hold the grate pins firmly and prevent them from becoming loose or dislodged during the pumping operation. By keeping the grate securely in position, it ensures that the hopper remains free from any unwanted materials and maintains a smooth and uninterrupted flow of concrete. Furthermore, the pin retainer also helps to prevent potential accidents or injuries by minimizing the risk of the grate coming loose or falling off during operation. This is particularly important when working in construction sites or other high-risk environments, where the safety of workers and equipment is of utmost importance. In summary, the role of a concrete pump hopper grate pin retainer is to provide stability and security to the hopper grate by holding the grate pins firmly in place. It ensures the smooth functioning of the concrete pump by preventing any debris from entering the hopper and maintains a safe working environment by minimizing the risk of accidents or injuries.

- Q: Are there any warranties or guarantees on concrete pump spare parts?

- Yes, there are warranties and guarantees available on concrete pump spare parts. Many reputable manufacturers and suppliers offer warranties to ensure the quality and performance of their products. These warranties typically cover defects in materials or workmanship and provide replacements or repairs within a specified time frame. It is important to check the terms and conditions of the warranty or guarantee provided by the specific supplier or manufacturer before purchasing concrete pump spare parts.

Send your message to us

Concrete Pump Truck Parts Elbow Bend DN100 R275 90DGR 148MM Mn13-4 Casting

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 140 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords