Concrete Pump Truck Parts Elbow Bend DN100 R275 90DGR 114.3MM Mn13-4 Casting

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 70 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

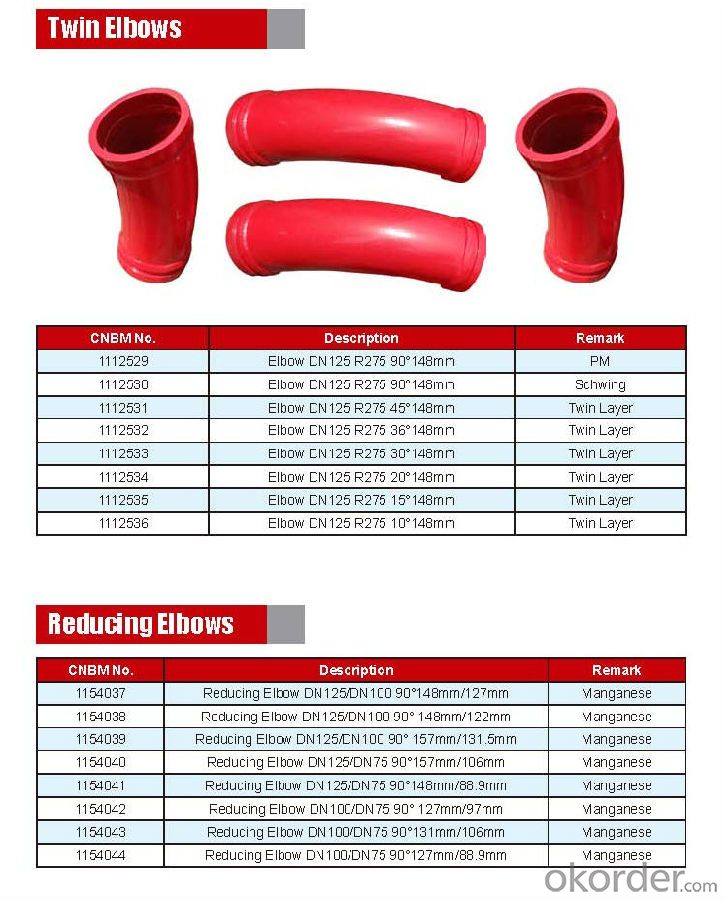

Widely used on concrete pump truck, concrete placing boom, trailer concrete pump etc, for concrete delivery pipe connection.

Our concrete pump bends have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc

Main Product Features:

1. Mainly adopt high wear resistant steel, and other material upon your request. High Chromium and manganese content, which enables a higher wear resisting ability and longer lifetime.

2. The inner side of this concrete pump elbow undergoes heat treatment, and then the hardness can reach 68HRC. The elbow possesses good toughness properties, and can well protect the inside. The experiment done abroad shows that the life of our concrete pump elbow can reach 35000-150000cbm,got the customers' praise.

3. Possess quality certification of ISO 9001:2000.

4. A wide range of specifications for you.

5. We can supply OEM service and can also produce according to your requirements.

6. Total series of concrete pump ELBOW for different brand concrete pump(PUTZMEISTER, SCHWING, CIFA, SANY, ZOOMLION, IHI, KYOKUTO Etc) available from us.

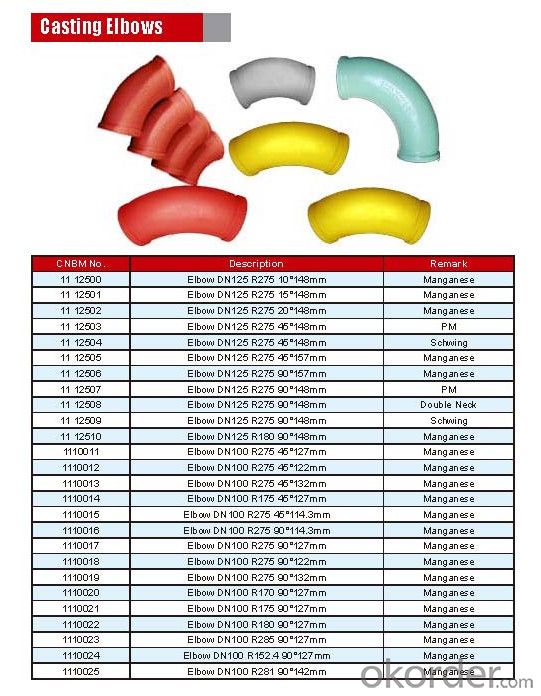

Product Specifications:

Technology: Cast

Dimension: DN100

Flange: 114.3mm

Radius: 275mm

Degree: 90D

Material: Mn13-4

Characteristics: According to our technology, the cast elbow also has high working pressure and burst pressure.

Package: Every 70pcs put in one seaworthy wooden box, and 20 boxes in one 20feet container.

FAQ:

Q1: How to confirm that your elbows could be used in our pump?

A1: We have been providing parts for nearly ten years, and cooperting with the agent of the world famous brand, possess near every kind of elbow in the market. What is more, we can produce as the customers request with drawing provided.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 20 workdays.

Q4: If we can produce some Concrete Pump Truck Parts according to customers request?

A4: Yes, we can produce Concrete Pump Truck Parts according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

- Q: What is the function of a concrete pump hopper grate pin?

- The purpose of a pin on a concrete pump hopper grate is to keep the grate securely in place and prevent it from moving or coming loose while concrete is being pumped. The pin acts as a locking mechanism, ensuring that the grate stays stable and does not pose any dangers or interrupt the pumping process. Furthermore, the pin allows for simple removal and replacement of the grate when needed, making it easier to maintain and clean the hopper. In conclusion, the concrete pump hopper grate pin is vital for preserving the reliability and effectiveness of the concrete pumping equipment.

- Q: What is the purpose of a concrete pump hopper agitator motor?

- The purpose of a concrete pump hopper agitator motor is to keep the concrete mixture inside the hopper agitated and prevent it from settling or hardening. This ensures a consistent and smooth flow of concrete through the pump, reducing the risk of blockages and improving overall efficiency during construction projects.

- Q: How can a faulty gearbox affect the pump's performance?

- A faulty gearbox can significantly impact the performance of a pump. The gearbox is responsible for transmitting power from the motor to the pump, and any dysfunction in this component can lead to various issues. Firstly, a faulty gearbox can cause a decrease in the pump's efficiency. The gearbox is designed to regulate the speed and torque of the pump, ensuring that it operates at optimal levels. If the gearbox is faulty, it may not be able to provide the necessary power to the pump, resulting in reduced performance and lower efficiency. This can lead to increased energy consumption and decreased overall productivity. Additionally, a faulty gearbox can cause the pump to experience excessive vibration and noise. A properly functioning gearbox helps to absorb and distribute the forces generated during operation, reducing vibration and noise levels. However, if the gearbox is faulty, it may fail to dampen these forces adequately, resulting in increased vibrations and noise. This can not only affect the pump's performance but also lead to premature wear and tear of other components, further impacting its overall efficiency. Furthermore, a faulty gearbox can result in inconsistent flow rates and pressure fluctuations. The gearbox plays a crucial role in controlling the speed and output of the pump. If the gearbox is malfunctioning, it may not be able to maintain a consistent flow rate or pressure, leading to fluctuations in the pump's performance. Inconsistent flow rates can disrupt processes that rely on precise volumes or pressures, causing inefficiencies and potential damage to downstream equipment. In conclusion, a faulty gearbox can have a detrimental effect on the performance of a pump. It can lead to decreased efficiency, increased vibrations and noise, as well as inconsistent flow rates and pressure fluctuations. Therefore, regular maintenance and prompt repair or replacement of faulty gearboxes are essential to ensure the optimal functioning of pumps and prevent any further damage or operational issues.

- Q: How can I minimize downtime during the replacement of concrete pump spare parts?

- Careful planning and efficient execution are essential for minimizing downtime when replacing concrete pump spare parts. Here are several strategies that can assist in achieving this goal: 1. Proactive maintenance: Establish a regular maintenance schedule to identify and replace worn-out parts before they malfunction. Regularly inspecting the concrete pump and its components can prevent unexpected breakdowns and reduce downtime. 2. Maintain spare parts inventory: Keep a stock of commonly needed spare parts, such as seals, filters, and hoses. This will significantly reduce the time spent on sourcing and ordering parts when a breakdown occurs. 3. Collaborate with dependable suppliers: Build relationships with reliable suppliers who can quickly provide high-quality spare parts. This ensures prompt access to the necessary components, minimizing delivery waiting time. 4. Train your team: Provide training to your maintenance and operational staff on efficiently identifying, troubleshooting, and replacing concrete pump spare parts. Equipping your team with the necessary skills enables them to promptly address issues, reducing overall downtime. 5. Schedule maintenance during low-demand periods: Plan maintenance and spare part replacement during periods of reduced demand or downtime. This could include weekends, holidays, or slower construction phases. Strategically scheduling the work ensures minimal impact on ongoing projects. 6. Optimize workflow: Identify areas causing delays or bottlenecks in your maintenance process. Seek opportunities to improve efficiency, such as optimizing the arrangement of spare parts, tools, and equipment, or implementing standardized repair and replacement procedures. 7. Utilize technology: Leverage technology to monitor the performance and condition of your concrete pump. Implementing a condition monitoring system can detect early signs of potential failures, allowing for proactive maintenance and part replacement. By implementing these strategies, you can minimize downtime during concrete pump spare part replacements, ensuring uninterrupted operations and maximizing productivity.

- Q: How often should hopper agitator shafts be inspected or replaced in a concrete pump?

- Hopper agitator shafts in a concrete pump should be regularly inspected and maintained to ensure optimal performance and prevent potential breakdowns. The frequency of inspection or replacement depends on several factors such as the usage and operating conditions of the pump. As a general guideline, it is recommended to inspect the hopper agitator shafts at least once every three to six months. During the inspection, the shafts should be checked for any signs of wear, damage, or misalignment. If any issues are detected, appropriate measures should be taken, such as lubrication, realignment, or replacement of damaged parts. However, it is important to note that the frequency of inspection may vary depending on the intensity of use, the type of materials being pumped, and the overall condition of the pump. For instance, if the pump is subjected to heavy-duty or continuous operation, it may be necessary to inspect the agitator shafts more frequently, such as on a monthly basis. Regular maintenance and inspection of hopper agitator shafts not only ensure the smooth operation of the concrete pump but also extend the lifespan of the equipment. Timely detection and resolution of any issues can prevent costly repairs or downtime in the future. Additionally, following the manufacturer's recommendations and guidelines for maintenance can help optimize the performance and reliability of the concrete pump.

- Q: What is the purpose of a concrete pump wear plate?

- To safeguard the pumping system against the abrasive characteristics of concrete, a concrete pump wear plate is employed. In the course of transferring concrete from the mixer to the construction site, the wear plate acts as a shield, preventing direct contact between the pumping system and the abrasive concrete. Consequently, the detrimental effects caused by the constant flow of concrete are minimized. The wear plate is typically constructed from durable materials such as hardened steel or tungsten carbide, which possess resistance against the abrasive forces exerted by the concrete. By implementing a wear plate, the lifespan of the pumping system is significantly prolonged, thereby reducing the frequency of repairs and replacements. Ultimately, the objective of a concrete pump wear plate is to ensure the efficient and dependable operation of concrete pumps by safeguarding and preserving the integrity of the pumping system.

- Q: How can one determine the correct voltage and current rating for electrical components in concrete pump spare parts?

- To determine the correct voltage and current rating for electrical components in concrete pump spare parts, one should refer to the manufacturer's specifications, which are typically provided in the product documentation or labeling. It is essential to match the voltage and current requirements of the electrical components to ensure proper functioning and prevent any potential damage or hazards.

- Q: What is the purpose of a concrete pump control panel?

- The purpose of a concrete pump control panel is to provide operators with a centralized interface to control various functions and parameters of the concrete pump. This control panel allows operators to start and stop the pump, control the speed and direction of the pump, and monitor and adjust the flow and pressure of the concrete being pumped. It also provides safety features such as emergency stop buttons and alarms to protect both the operators and the equipment. Additionally, the control panel may include diagnostic features that display real-time data and alerts for maintenance and troubleshooting purposes. Overall, the purpose of a concrete pump control panel is to enhance efficiency, accuracy, and safety in the operation of the concrete pumping process.

- Q: Can I get spare parts for concrete pump boom arms and pipes?

- Concrete pump boom arms and pipes can definitely be replaced with spare parts. Many suppliers and manufacturers specialize in providing these spare parts for concrete pumps. These spare parts include boom arms, pipes, couplings, gaskets, seals, and other components necessary for proper concrete pump function. To find these spare parts, you can conduct an online search. Numerous websites and online stores offer a wide range of options. It is crucial to purchase spare parts from reputable suppliers to ensure their quality and compatibility with your specific concrete pump model. Moreover, local dealers and distributors also stock spare parts for concrete pumps. You can inquire with them or visit their stores to find the necessary spare parts for your boom arms and pipes. Efficient and safe operation of a concrete pump requires regular maintenance and replacement of worn-out or damaged parts. By investing in high-quality spare parts, you can extend the lifespan of your equipment and ensure optimal performance.

- Q: How do I properly maintain and replace concrete delivery pipes in concrete pump spare parts?

- Proper maintenance and replacement of concrete delivery pipes in concrete pump spare parts involve a few key steps. Firstly, regular inspection of the pipes is essential to identify any signs of wear, corrosion, or damage. It is important to clean the pipes thoroughly after each use to prevent the buildup of concrete residue. Additionally, using a high-quality lubricant during operation can help minimize friction and prolong the life of the pipes. When it comes to replacement, it is crucial to choose pipes that are compatible with the specific model of the concrete pump. The replacement pipes should be made from high-quality materials that can withstand the pressure and abrasive nature of concrete. It is advisable to consult the manufacturer's guidelines or seek professional advice to ensure the proper selection and installation of replacement pipes. Overall, regular inspection, cleaning, and lubrication, along with proper selection and installation of replacement pipes, are essential for maintaining the efficiency and longevity of concrete delivery pipes in concrete pump spare parts.

Send your message to us

Concrete Pump Truck Parts Elbow Bend DN100 R275 90DGR 114.3MM Mn13-4 Casting

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 70 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords