Concrete Pump Truck Parts Bend DN125 R500 45DRG

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Widely used on concrete pump truck, concrete placing boom, trailer concrete pump etc, for concrete delivery pipe connection.

Our concrete pump elbows have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc.

Main Product Features:

1. High Chromium and manganese content, which enables a higher wear resisting ability and longer lifetime.Two production lines, wear-resistant pipe 100pcs daily, trailer pipe 400pcs daily.

2. The experiment done abroad shows that the life of our concrete pump pipes can reach 6000-15000cbm,got the customers' praise.Seaworthy packing or as customers’ request.

3. Possess quality certification of ISO 9001:2000. Can pass CE test.

4. OEM service available.

5. Applications: Putzmeister, Schwing, Zoomlion, SANY, etc.

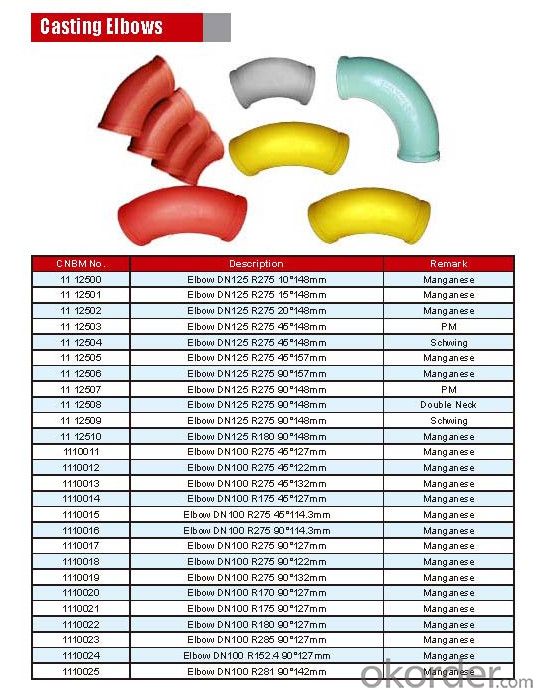

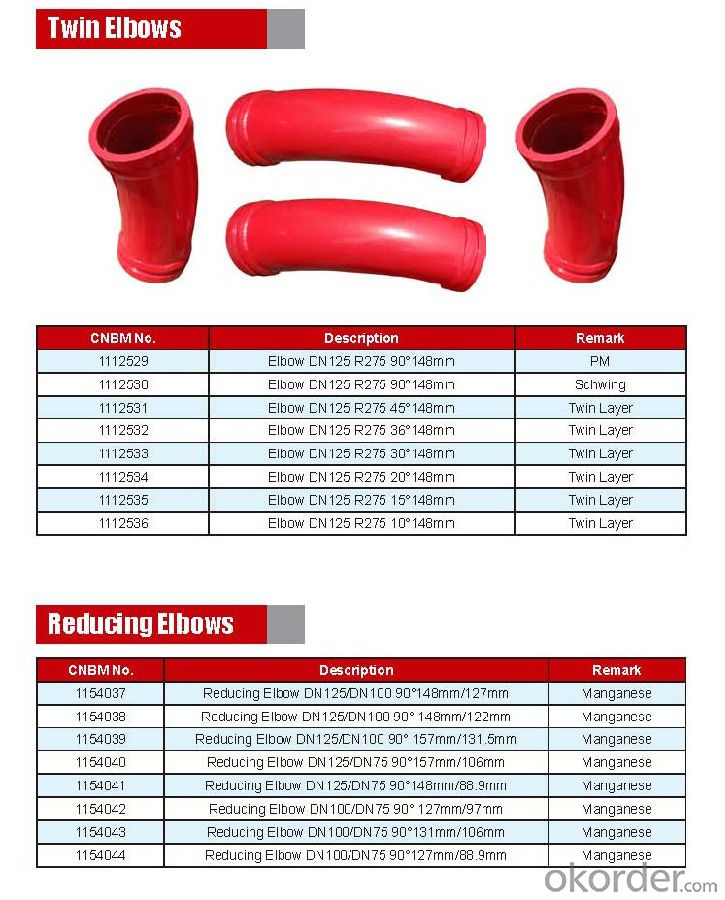

Product Specifications:

Technical: Casting

Radius: 500mm

Degree: 45

Material: Mn13-4

Characteristics: According to our technology, the cast elbow also has high working pressure and burst pressure.

Package: PP woven bag and plastic cap

FAQ:

Q1: How to confirm that your pipes could be used in our pump?

A1: We have been providing parts for nearly ten years, and cooperating with the agent of the world famous brand, possess near every kind of pipe in the market. What is more, we can produce as the customers’ request with drawing provided.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 5-15 workdays.

Q4: If we can produce some Concrete Pump Truck Parts according to customers request?

A4: Yes, we can produce Concrete Pump Truck Parts according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Other Products:

- Q: How do I determine the correct temperature ratings for concrete pump spare parts?

- To determine the correct temperature ratings for concrete pump spare parts, you should refer to the manufacturer's guidelines or specifications. These documents usually provide information on the recommended temperature range within which the parts can function effectively and safely. It is essential to follow these guidelines to ensure the longevity and performance of the spare parts in your concrete pump system.

- Q: How can one ensure proper functioning of concrete pump spare parts after installation?

- To ensure proper functioning of concrete pump spare parts after installation, it is important to follow a few key steps. Firstly, it is crucial to carefully inspect and clean the parts before installation to ensure they are free from any debris or damage. Additionally, it is essential to use high-quality parts from reputable manufacturers to ensure durability and reliability. Regular maintenance and lubrication of the spare parts is also necessary to prevent wear and tear. Lastly, it is important to operate the concrete pump within its specified limits and avoid overloading, as this can cause stress on the spare parts and lead to malfunctioning.

- Q: How often should concrete pump pressure gauges be inspected and replaced?

- Regular inspections of concrete pump pressure gauges are necessary to ensure they are accurate and functioning properly. The frequency of inspections and replacements may vary depending on the specific conditions and usage of the pump. However, it is generally recommended to inspect and replace pressure gauges at least once a year or after every 500 pumping hours, whichever comes first. This regular schedule helps prevent any potential accuracy or functionality issues that could impact the safety and efficiency of the pumping operations. It is also essential to adhere to the manufacturer's recommendations and guidelines for pressure gauge maintenance and replacement to maintain optimal performance and longevity.

- Q: How often should concrete pump pistons be replaced?

- The frequency at which concrete pump pistons should be replaced depends on various factors such as the usage, maintenance, and the quality of the pistons. In general, it is recommended to inspect the pistons regularly for signs of wear and tear, including cracks, pitting, or scoring. If any of these signs are observed, it is advisable to replace the pistons immediately to prevent potential failures or leaks. Concrete pump pistons typically have a lifespan ranging from 25,000 to 75,000 cubic yards of concrete pumped, but this can vary based on the specific conditions and operating practices. For instance, if the concrete being pumped contains abrasive materials or if the pump is used intensively or under harsh conditions, the pistons may wear out more quickly. Additionally, proper maintenance practices can extend the lifespan of the pistons. This includes regular cleaning and lubrication, keeping the pump well-maintained, and ensuring that the pistons are properly aligned and not subjected to excessive pressure or stress. Ultimately, it is crucial to monitor the condition of the pistons closely and consult the manufacturer's recommendations or seek advice from a professional to determine the appropriate replacement interval for the specific concrete pump being used.

- Q: How do I properly maintain and replace hydraulic valves in concrete pump spare parts?

- Proper maintenance and replacement of hydraulic valves in concrete pump spare parts involve a few key steps. Firstly, it is crucial to regularly inspect the valves for any signs of wear, damage, or leakage. This can be done by checking the valve body, seals, and connections. Secondly, ensure that the valves are lubricated according to the manufacturer's recommendations to prevent friction and extend their lifespan. Additionally, it is essential to adhere to the specified pressure and temperature limits during operation, as exceeding these limits can lead to valve failure. When it comes to replacement, it is recommended to consult the equipment manual or seek professional assistance to ensure that the correct valves are selected and installed accurately. Regular maintenance and timely replacement of hydraulic valves will ensure the optimal performance and longevity of the concrete pump spare parts.

- Q: Can concrete pump spare parts be replaced individually, or should they be replaced as a set?

- Concrete pump spare parts can be replaced individually, as there is no requirement to replace them as a set. This allows for more cost-effective and efficient maintenance, as only the specific part that needs replacement can be addressed.

- Q: How often should hopper agitator shaft bearings be inspected or replaced in a concrete pump?

- The hopper agitator shaft bearings in a concrete pump should be inspected regularly, at least once every six months, to ensure proper functioning. However, the exact frequency of replacement would depend on the manufacturer's recommendations, the intensity of usage, and the condition of the bearings. It is crucial to monitor the bearings for any signs of wear, damage, or excessive vibration, as this can lead to equipment failure and potential safety hazards.

- Q: Can concrete pump spare parts be retrofitted to older pump models?

- Yes, concrete pump spare parts can often be retrofitted to older pump models. Many manufacturers design their spare parts to be compatible with multiple pump models, including older ones. However, it is important to note that not all spare parts may be suitable for retrofitting, as compatibility can vary depending on the specific pump model and the part in question. It is advisable to consult with the manufacturer or a qualified technician to ensure that the spare parts are compatible and can be safely retrofitted to older pump models.

- Q: What is the purpose of a concrete pump boom?

- A concrete pump boom serves the purpose of efficiently and effectively transferring concrete from the mixer truck to the desired location on a construction site. Typically mounted on a truck or trailer, the boom consists of interconnected sections that can be extended and maneuvered to access otherwise difficult areas. Concrete pump booms offer numerous advantages compared to traditional concrete placement methods. Firstly, they greatly reduce the amount of labor needed for concrete placement. The boom can reach over obstacles like buildings or structures, eliminating the need for manual pouring or crane usage. This saves both time and money during construction projects. Moreover, concrete pump booms enable precise and accurate concrete placement. The boom can be controlled remotely, allowing the operator to position the nozzle exactly where the concrete is required. This ensures a more uniform and evenly distributed concrete placement, resulting in a higher quality finished product. Furthermore, concrete pump booms enhance safety on construction sites. By eliminating the need for workers to physically transport and pour concrete, the risk of injuries and accidents is significantly reduced. The boom also enables concrete placement in hard-to-reach areas, minimizing the need for workers to climb or work at heights, further enhancing safety. In conclusion, a concrete pump boom serves to provide a more efficient, precise, and safe method for transferring and placing concrete on construction sites. Its ability to overcome obstacles, accurately control placement, and reduce labor requirements make it an invaluable tool in the construction industry.

- Q: How often should the concrete pump cylinder be replaced?

- The concrete pump cylinder should be replaced when it shows signs of wear and tear or if it becomes damaged. The frequency of replacement can vary depending on factors such as usage, maintenance, and quality of materials used. Regular inspections and proper maintenance can help prolong the lifespan of the cylinder.

Send your message to us

Concrete Pump Truck Parts Bend DN125 R500 45DRG

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords