Concrete Pump Truck Parts Bend DN125 R1000 90DRG

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Widely used on concrete pump truck, concrete placing boom, trailer concrete pump etc, for concrete delivery pipe connection.

Our concrete pump pipes have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc.

Main Product Features:

High Chromium and manganese content, which enables a higher wear resisting ability and longer lifetime.High Chromium and manganese content, which enables a higher wear resisting ability and longer lifetime.

The inner side of this concrete pump pipe can undergoes heat treatment, and then the hardness can reach 63HRC.

Possess quality certification of ISO 9001:2000. Can pass CE test.

A wide range of specifications for you.

We can supply OEM service and can also produce according to your requirements.

Total series of concrete pump pipes for different brand concrete pump(PUTZMEISTER, SCHWING, CIFA, SANY, ZOOMLION, IHI, KYOKUTO Etc) available from us.

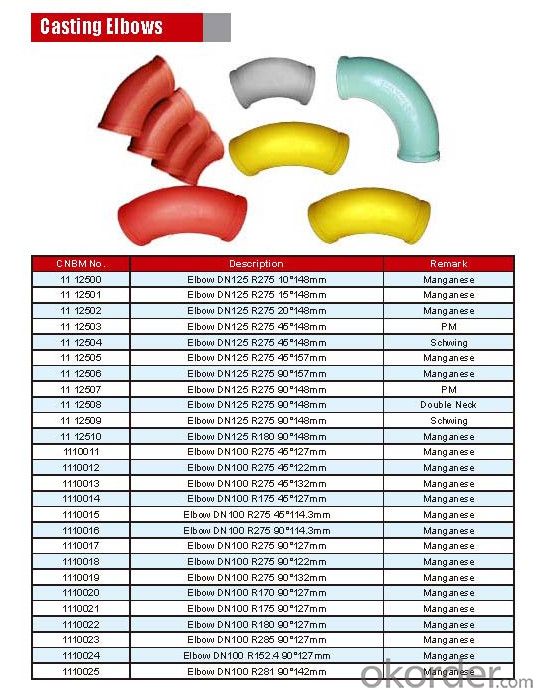

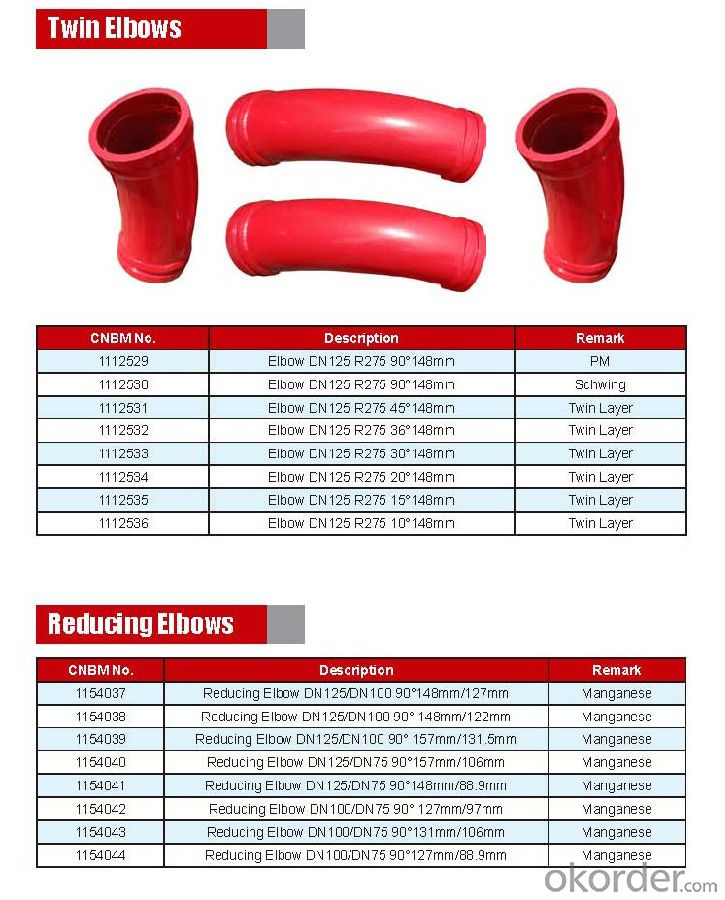

Product Specifications:

Technical: Casting

Radius: 1000mm

Degree: 90

Material: Mn13-4

Characteristics: According to our technology, the cast elbow also has high working pressure and burst pressure.

Package: PP woven bag and plastic cap

FAQ:

Q1: How to confirm that your pipes could be used in our pump?

A1: We have been providing parts for nearly ten years, and cooperating with the agent of the world famous brand, possess near every kind of pipe in the market. What is more, we can produce as the customers’ request with drawing provided.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 5-15 workdays.

Q4: If we can produce some Concrete Pump Truck Parts according to customers request?

A4: Yes, we can produce Concrete Pump Truck Parts according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Other Products:

- Q: Are there any specific recommendations for the inspection and testing of concrete pump spare parts?

- Yes, there are specific recommendations for the inspection and testing of concrete pump spare parts. Firstly, it is important to visually inspect the spare parts for any signs of damage, such as cracks, dents, or excessive wear. This can be done by carefully examining the parts and looking for any irregularities or abnormalities. Next, it is recommended to conduct non-destructive testing (NDT) to ensure the integrity and quality of the spare parts. NDT methods such as ultrasonic testing, magnetic particle testing, or dye penetrant testing can be used to detect any hidden defects or flaws in the parts. These tests can help identify potential issues that may affect the performance or safety of the concrete pump. In addition, it is advisable to check the dimensions and tolerances of the spare parts to ensure they meet the manufacturer's specifications. This can be done using precision measuring tools and comparing the measurements with the required specifications. Any deviations should be noted and addressed accordingly. Furthermore, functional testing should be conducted to ensure the spare parts are operating as intended. This can involve installing the parts in the concrete pump and carrying out various tests to verify their functionality and performance. For example, the pump can be tested for its flow rate, pressure, and efficiency to ensure optimal performance. Lastly, it is crucial to follow the manufacturer's guidelines and recommendations for the inspection and testing of concrete pump spare parts. These guidelines may provide specific instructions and procedures for inspecting and testing each type of spare part, ensuring that they are done accurately and safely. It is important to consult the manufacturer's documentation and seek professional advice if needed.

- Q: Can I get spare parts for both concrete pumps with and without emergency stop systems?

- Yes, spare parts are available for both concrete pumps with and without emergency stop systems. These spare parts can be sourced from authorized dealers or manufacturers, ensuring the proper functioning and maintenance of both types of concrete pumps.

- Q: Can I get spare parts for both concrete pumps with and without boom stabilizers?

- Both concrete pumps with and without boom stabilizers have spare parts available. Concrete pump manufacturers typically offer a wide range of spare parts to ensure the longevity and smooth operation of their equipment. These spare parts may include hydraulic components, valves, hoses, seals, wear plates, pipes, and more. Whether your concrete pump has a boom stabilizer or not, you can easily find and purchase spare parts from the manufacturer or authorized dealers. Furthermore, there are aftermarket suppliers who specialize in providing spare parts for various concrete pump models. Therefore, regardless of the specific features of your concrete pump, you can be confident that spare parts are readily available to maintain the smooth functioning of your equipment.

- Q: How often should concrete pump pistons be replaced?

- The replacement frequency for concrete pump pistons depends on several factors, including usage, maintenance, and piston quality. It is generally advised to regularly inspect the pistons for signs of wear and tear, such as cracks, pitting, or scoring. If any of these signs are detected, it is recommended to replace the pistons immediately to prevent potential failures or leaks. Concrete pump pistons typically last between 25,000 and 75,000 cubic yards of pumped concrete, although this can vary depending on specific conditions and operating practices. For example, if the concrete being pumped contains abrasive materials or if the pump is used intensively or under harsh conditions, the pistons may wear out more quickly. Furthermore, proper maintenance practices can prolong the lifespan of the pistons. This includes regular cleaning and lubrication, maintaining the pump in good condition, and ensuring the pistons are correctly aligned and not subjected to excessive pressure or stress. In conclusion, closely monitoring the condition of the pistons and referring to the manufacturer's recommendations or seeking advice from a professional is essential to determine the appropriate replacement interval for the specific concrete pump being utilized.

- Q: What is the purpose of a concrete pump hopper grate?

- The purpose of a concrete pump hopper grate is to prevent large debris or foreign objects from entering the pump and potentially causing damage or blockages. The grate acts as a filter, allowing only smaller particles and liquid concrete to pass through while blocking larger materials such as rocks, wood, or other debris. This helps to maintain the efficiency and functionality of the pump, ensuring a smooth and uninterrupted flow of concrete. Additionally, the grate also helps to protect the pump's internal components, such as the impeller and valves, from potential damage caused by large objects. Overall, the concrete pump hopper grate plays a crucial role in maintaining the quality and reliability of the pumping process, preventing potential issues and ensuring a successful concrete placement.

- Q: How to calculate the power of concrete pump motor?

- Second, the amount of transport is the amount of export pressure is determined,

- Q: How often should hydraulic cylinders be inspected or replaced in a concrete pump?

- Hydraulic cylinders in a concrete pump should be inspected regularly, ideally every 6 to 12 months, to ensure their proper functioning. Replacement of hydraulic cylinders should be done only when necessary, such as in cases of significant wear and tear, severe damage, or if they fail to meet safety standards.

- Q: Do concrete pump spare parts come with a warranty?

- Yes, concrete pump spare parts do come with a warranty. The warranty period may vary depending on the manufacturer and the specific part being purchased. Generally, reputable manufacturers and suppliers offer warranties on their spare parts to provide assurance to customers about the quality and reliability of the product. It is important to carefully review the terms and conditions of the warranty to understand what is covered and for how long. If any defects or issues arise during the warranty period, customers can typically get a replacement or have the part repaired at no additional cost.

- Q: How can one ensure proper alignment and positioning of concrete pump spare parts during installation?

- Ensuring proper alignment and positioning of concrete pump spare parts during installation is crucial for the efficient and safe operation of the pump. Here are some key steps to follow to achieve the desired alignment and positioning: 1. Thoroughly read and understand the manufacturer's instructions: Before starting the installation process, carefully go through the manufacturer's instructions and guidelines. This will provide you with important information on the correct alignment and positioning of the spare parts specific to your concrete pump model. 2. Prepare a suitable work area: Clear the work area of any debris, dust, or obstacles that might hinder the installation process. Ensuring a clean and organized work environment will make it easier to position and align the spare parts accurately. 3. Utilize proper lifting equipment: Concrete pump spare parts can be heavy and require special lifting equipment to avoid damage or injuries. Use cranes, hoists, or forklifts to lift and position the spare parts accurately and safely. 4. Use precision measuring tools: Invest in high-quality measuring tools, such as laser levels, alignment guides, and precision measuring tapes. These tools will help you ensure precise alignment and positioning of the spare parts during installation. 5. Double-check dimensions and specifications: Before installing any spare part, cross-check the dimensions and specifications provided by the manufacturer with the actual part. This will help you identify any discrepancies or potential issues that need to be addressed before installation. 6. Follow a systematic installation process: Start with the main components of the concrete pump and gradually work your way towards the spare parts. Follow a step-by-step approach, aligning and positioning each spare part meticulously according to the manufacturer's instructions. 7. Seek professional assistance if needed: If you are unsure about the proper alignment and positioning of certain spare parts, do not hesitate to seek professional assistance. Consulting with experienced technicians or contacting the manufacturer's customer support can provide valuable guidance and ensure correct installation. 8. Conduct a final inspection: Once all the spare parts are installed, conduct a thorough inspection to verify the alignment and positioning. Check for any visible gaps, misalignments, or irregularities. Rectify any issues immediately to ensure proper function and longevity of the concrete pump. By following these steps and paying attention to detail, you can ensure the proper alignment and positioning of concrete pump spare parts during installation, resulting in a reliable and efficient pump system.

- Q: What are the different types of concrete pump rubber pistons?

- In the market, one can find a variety of concrete pump rubber pistons, each with its own purpose and specifications. Commonly used types include: 1. Single-Action Piston: This piston is designed to push the concrete forward during pumping. It moves in one direction, ensuring a consistent and efficient flow of concrete. 2. Double-Action Piston: Unlike the single-action piston, this one can move in both directions. It offers more versatility in pumping, especially when there are obstacles or restrictions in the pump line. 3. Steel Reinforced Piston: To provide extra strength and durability, these pistons are reinforced with steel. They are often used for high-pressure pumping or when handling abrasive materials. 4. Polyurethane Piston: These pistons are known for their exceptional wear resistance and long lifespan. They are commonly used in demanding pumping conditions where durability is crucial. 5. Rubber Sponge Piston: Designed with a soft and flexible surface, rubber sponge pistons can conform to irregularities in the pump line. They are particularly useful for navigating bends or corners in the line. 6. Bonded Piston: Bonded pistons are created by bonding a rubber or polyurethane material to a metal core. This combination offers the flexibility of rubber and the strength of metal, making them suitable for a variety of pumping applications. Choosing the right concrete pump rubber piston is crucial for project success. Factors such as pumping pressure, material being pumped, and environmental conditions should be taken into account to ensure optimal performance and longevity of the piston.

Send your message to us

Concrete Pump Truck Parts Bend DN125 R1000 90DRG

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords