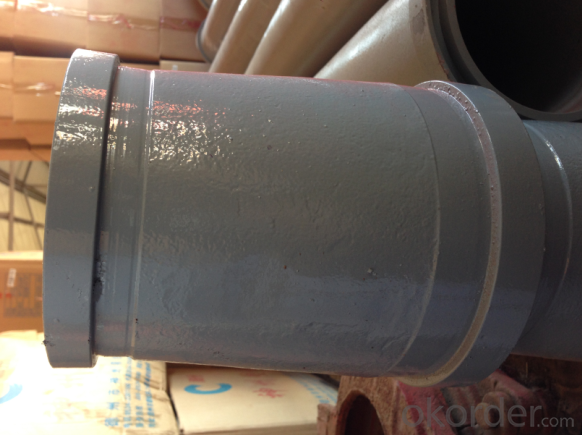

Concrete Pump Truck Parts Bend DN125 R500 90DRG

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Widely used on concrete pump truck, concrete placing boom, trailer concrete pump etc, for concrete delivery bend connection.

Our concrete pump bends have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc.

Main Product Features:

Two production lines, wear-resistant bend 100pcs daily, trailer bends 400pcs daily.

Seaworthy packing or as customers’ request. Service life:6000-15000 CBM Concrete.

Possess quality certification of ISO 9001:2000. Can pass CE test.

A wide range of specifications for you./ We have been providing parts for nearly ten years, and cooperating with the agent of the world famous brand, possess near every kind of bend in the market.

We can supply OEM service and can also produce according to your requirements.

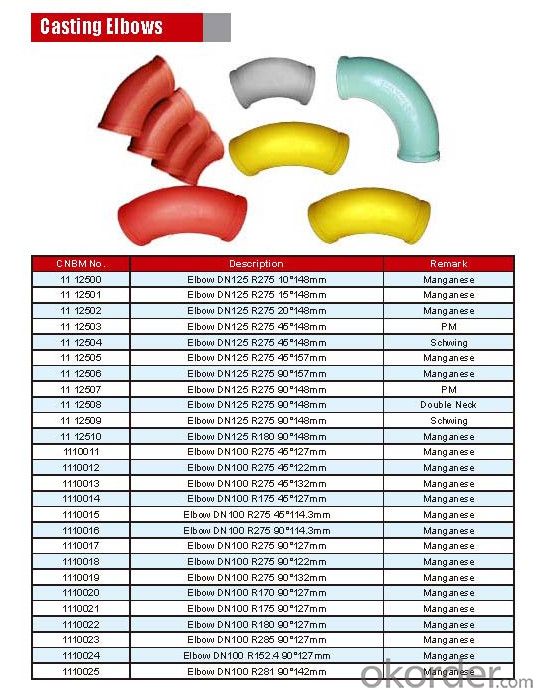

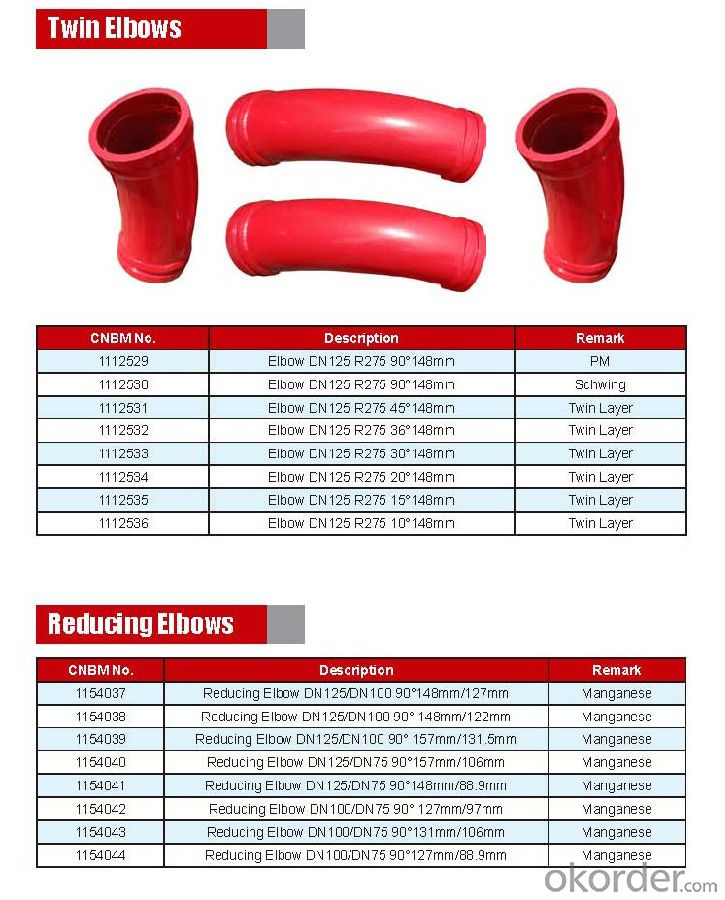

Applications: Putzmeister, Schwing, Zoomlion, SANY, etc.

Product Specifications:

Technical: Casting

Radius: 500mm

Degree: 90

Material: Mn13-4

Characteristics: According to our technology, the casting bends also has high working pressure and burst pressure.

Package: PP woven bag and plastic cap

FAQ:

Q1: How to confirm that your bends could be used in our pump?

A1: We have been providing parts for nearly ten years, and cooperating with the agent of the world famous brand, possess near every kind of bend in the market. What is more, we can produce as the customers’ request with drawing provided.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 5-15 workdays.

Q4: If we can produce some Concrete Pump Truck Parts according to customers request?

A4: Yes, we can produce Concrete Pump Truck Parts according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Other Products:

- Q: Are there any specific guidelines for the installation of sensors or transmitters in concrete pump spare parts?

- Yes, there are specific guidelines for the installation of sensors or transmitters in concrete pump spare parts. These guidelines are important to ensure the proper functioning and accurate readings of the sensors or transmitters. Firstly, it is crucial to carefully select the location for installing the sensors or transmitters. The chosen location should allow for easy access and maintenance, while also ensuring that the sensors or transmitters are not exposed to excessive vibration, moisture, or extreme temperatures. Secondly, it is recommended to use appropriate mounting hardware for securing the sensors or transmitters to the concrete pump spare parts. This hardware should be able to withstand the operating conditions and any potential vibrations or shocks that may occur during the pumping process. Additionally, it is important to follow the manufacturer's instructions for wiring and connection of the sensors or transmitters. Proper wiring and connection are essential to ensure accurate and reliable data transmission. Furthermore, regular inspections and maintenance should be conducted to ensure that the sensors or transmitters are functioning correctly. This includes checking for any loose connections, signs of wear or damage, and ensuring that the sensors or transmitters are calibrated properly. Overall, following these specific guidelines for the installation of sensors or transmitters in concrete pump spare parts can help to ensure their optimal performance and longevity, ultimately enhancing the efficiency and safety of the concrete pumping operation.

- Q: How often should hopper grate clamps be inspected or replaced in a concrete pump?

- Hopper grate clamps in a concrete pump should be inspected regularly, preferably on a monthly basis, to ensure they are in proper working condition. However, the frequency of inspection may vary depending on the usage and operating conditions of the concrete pump. If the concrete pump is used extensively or subjected to harsh environments, more frequent inspections may be necessary, such as every two weeks or even weekly. On the other hand, if the pump is used less frequently or operates in less demanding conditions, inspections can be done less frequently, such as every two to three months. The purpose of these inspections is to identify any signs of wear, damage, or deterioration in the hopper grate clamps. Any loose or worn-out clamps should be promptly replaced to prevent accidents or disruptions during concrete pumping operations. It is crucial to prioritize safety and ensure that the hopper grate clamps are in good condition to secure the hopper grate effectively and prevent any unwanted material spillage. Regular inspections and timely replacements of hopper grate clamps will help maintain the efficiency and reliability of the concrete pump, ensuring uninterrupted operation and minimizing the risk of any potential issues.

- Q: What is the role of a concrete pump agitator shaft seal?

- The role of a concrete pump agitator shaft seal is to prevent leakage of concrete slurry or other fluids from the agitator shaft, ensuring that the pump operates efficiently and without any loss or contamination of the material being pumped.

- Q: How can a damaged concrete pump hopper affect the pumping process?

- The pumping process can be negatively impacted by a damaged concrete pump hopper in several ways. To begin with, efficiency and productivity can decrease when the hopper is damaged. The hopper's role is to hold and feed the concrete mixture into the pump. Any damage to the hopper can disrupt the continuous flow of concrete, leading to frequent interruptions in the pumping process. This causes delays and reduces the overall output of the pump. Furthermore, the quality of the concrete being pumped can be affected by a damaged hopper. The hopper is designed to ensure proper mixing and consistency of the concrete mixture before it is pumped. If the hopper is damaged, it may not effectively mix the concrete, resulting in inconsistencies in the mixture. This can lead to poor-quality concrete being pumped, compromising the structural integrity and durability of the final product. Additionally, a damaged hopper can pose safety risks for the workers involved in the pumping process. Sharp edges or loose parts on a damaged hopper can cause injury if not addressed properly. Moreover, if the hopper is not functioning correctly, it may cause clogs or blockages in the pump, leading to pressure build-up and potential accidents. Finally, maintenance and repair costs can increase due to a damaged hopper. An imperfect hopper may require frequent repairs or even replacement, which can be time-consuming and expensive. Regular maintenance and inspection of the hopper are crucial to identify any damages early on and prevent them from escalating into more significant issues. In conclusion, a damaged concrete pump hopper has significant implications for the pumping process, including reduced efficiency, compromised concrete quality, safety risks, and increased maintenance costs. Regular inspection, maintenance, and timely repairs are essential to ensure the smooth operation of the pump and the delivery of high-quality concrete.

- Q: How do I properly maintain and replace hydraulic filters in concrete pump spare parts?

- To ensure your equipment's longevity and efficiency, it is crucial to properly maintain and replace hydraulic filters in concrete pump spare parts. Here are some guidelines to follow: 1. Familiarize yourself with the manufacturer's recommendations: Understand the maintenance and replacement guidelines provided by the manufacturer. These instructions may vary based on the specific pump model and filter type. 2. Regularly inspect the filters: Conduct regular inspections to identify any signs of damage, clogging, or excessive wear in the hydraulic filters. Look out for dirt, debris, or other contaminants that may hinder their performance. Address any issues promptly. 3. Establish a maintenance schedule: Implement a regular maintenance schedule for the hydraulic filters. This should include regular inspections, cleaning, and replacement intervals. Adhering to a schedule will prevent unexpected breakdowns and keep the concrete pump running smoothly. 4. Clean the filters: If the hydraulic filters can be cleaned and reused, ensure to follow the proper cleaning procedure. This typically involves removing the filter, washing it with a suitable cleaning solution, and allowing it to dry thoroughly before reinstalling. Take care not to damage the filter during the cleaning process. 5. Replace as necessary: Over time, hydraulic filters become less effective at filtering out contaminants. It is important to replace them according to the manufacturer's recommended intervals or sooner if they appear excessively dirty or damaged. Always use genuine spare parts to ensure compatibility and optimal performance. 6. Install correctly: When replacing hydraulic filters, ensure they are installed correctly and securely. Pay attention to any seals or gaskets that may need replacement as well. Improper installation can lead to leaks or reduced filtration efficiency. 7. Monitor performance: After replacing the hydraulic filters, closely monitor the pump's performance. Watch for changes in pressure, flow rate, or unusual noises. If any abnormalities are observed, it may indicate a problem with the filter or other components, requiring further investigation. By following these steps, you can effectively maintain and replace hydraulic filters in your concrete pump spare parts, ensuring optimal performance and extending the equipment's lifespan.

- Q: How does a hopper agitator blade ensure smooth concrete flow?

- A hopper agitator blade ensures smooth concrete flow by effectively mixing and breaking up any clumps or air pockets in the concrete mixture. The blade is specifically designed to be placed inside the hopper, where it rotates and agitates the concrete, ensuring that it remains in a uniform and consistent state. As the blade rotates, it helps to disperse any aggregates that may have settled at the bottom of the hopper, preventing them from causing blockages or uneven distribution during the pouring process. This continuous mixing action ensures that the concrete remains well-mixed and free-flowing, allowing for a smooth and even distribution when it is discharged from the hopper. Moreover, the agitator blade also helps to break up any air bubbles that may have formed within the concrete mixture. These air bubbles can weaken the concrete's structural integrity and result in an uneven finish. By agitating the concrete, the blade helps to release trapped air, promoting a more consistent and dense mixture. In summary, a hopper agitator blade ensures smooth concrete flow by effectively mixing the concrete, breaking up any clumps or air pockets, and promoting a consistent and uniform mixture. This ensures that the concrete flows smoothly and evenly during the pouring process, resulting in a high-quality finished product.

- Q: Are there any online resources or manuals available for concrete pump spare parts?

- Yes, there are several online resources and manuals available for concrete pump spare parts. Many manufacturers and suppliers have websites where you can find detailed information about various spare parts, their specifications, and ordering details. Additionally, there are online marketplaces and forums dedicated to construction equipment, where you can find comprehensive catalogs, user manuals, and even discussion threads related to concrete pump spare parts.

- Q: What are the advantages of using genuine spare parts for my concrete pump?

- There are numerous benefits to utilizing authentic spare parts for your concrete pump. Firstly, these genuine components are specifically designed and produced by the original equipment manufacturer (OEM) for your concrete pump. This guarantees a perfect fit and optimal functioning with your particular model. By using genuine parts, you can avoid compatibility issues or malfunctions that may arise from using aftermarket or counterfeit parts. Furthermore, authentic spare parts are crafted from high-quality materials and undergo rigorous testing to meet stringent quality standards. This ensures their durability, reliability, and performance, resulting in a longer service life and reduced downtime for your concrete pump. Genuine parts are engineered to withstand the demanding conditions and heavy loads commonly encountered by concrete pumps. Moreover, the use of authentic spare parts helps preserve the warranty and integrity of your concrete pump. Many manufacturers offer warranties that cover the utilization of genuine parts. By utilizing genuine parts, you can take advantage of the warranty benefits and avoid any potential problems that may arise from using non-genuine parts, which could invalidate the warranty. In addition, authentic spare parts often come with technical support and expertise from the manufacturer. OEMs possess extensive knowledge and experience with their equipment, and their technical support team can provide guidance, advice, and troubleshooting assistance in the event of any issues. This can be highly advantageous in minimizing downtime and maximizing the efficiency of your concrete pump. Lastly, the use of authentic spare parts ensures the safety of your equipment and operators. Genuine parts are manufactured to meet strict safety regulations and standards, reducing the risk of accidents or failures that can result from using substandard or counterfeit parts. The safety and well-being of your team should always be a top priority, and the use of genuine parts helps guarantee their protection. In conclusion, the utilization of authentic spare parts for your concrete pump offers a range of advantages, including compatibility, quality, durability, warranty coverage, technical support, and safety. Investing in genuine parts not only enhances the performance and longevity of your equipment but also provides peace of mind for both you and your team.

- Q: How do I ensure the reliability of concrete pump spare parts in critical applications?

- To ensure the reliability of concrete pump spare parts in critical applications, there are several steps you can take. 1. Choose reputable suppliers: Purchase spare parts from trusted and reliable suppliers who have a proven track record in the industry. Look for suppliers who specialize in concrete pump spare parts and have a good reputation for quality. 2. Conduct thorough research: Before making a purchase, research the specific spare parts you need and learn about their quality, durability, and performance. Read customer reviews and seek recommendations from industry professionals to ensure you are selecting the most reliable parts for your critical application. 3. Opt for genuine parts: Whenever possible, choose genuine spare parts provided by the original equipment manufacturer (OEM). These parts are specifically designed to fit and function with your concrete pump, ensuring optimal performance and reliability. 4. Regular maintenance and inspections: Implement a regular maintenance schedule and conduct thorough inspections of your concrete pump and its spare parts. This will help identify any potential issues or wear and tear before they become critical problems. 5. Quality control and testing: Before using new spare parts, conduct quality control checks and testing to ensure they meet the required standards. This can involve inspection of materials, dimensional checks, and performance testing to ensure reliability in critical applications. 6. Keep spare parts inventory: Maintain an adequate inventory of essential spare parts to minimize downtime in case of any failures. This will allow for timely replacement and reduce the chances of using substandard or counterfeit parts in critical applications. By following these steps, you can enhance the reliability of concrete pump spare parts in critical applications and minimize the risk of unexpected failures.

- Q: How often should concrete pump remote control batteries be replaced?

- Concrete pump remote control batteries should be replaced as needed, typically when they no longer hold a charge or fail to power the remote control effectively. The frequency of replacement will depend on factors such as battery quality, usage, and maintenance.

Send your message to us

Concrete Pump Truck Parts Bend DN125 R500 90DRG

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords