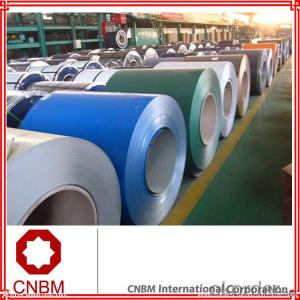

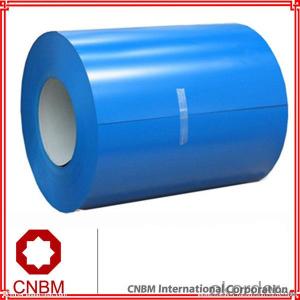

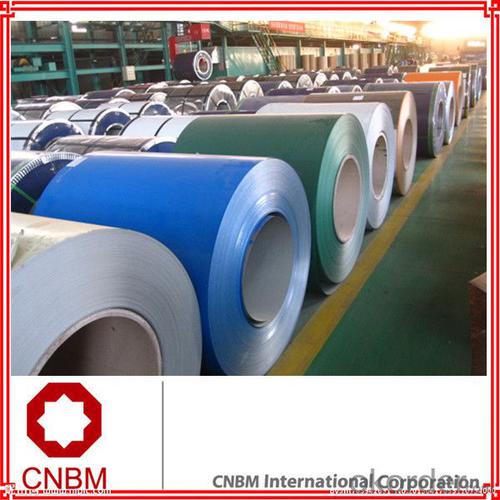

Color coated steel coil base material GL

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 31234 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

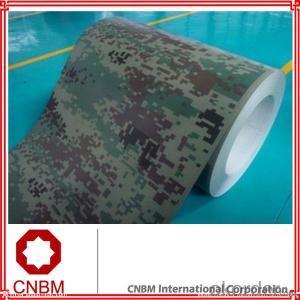

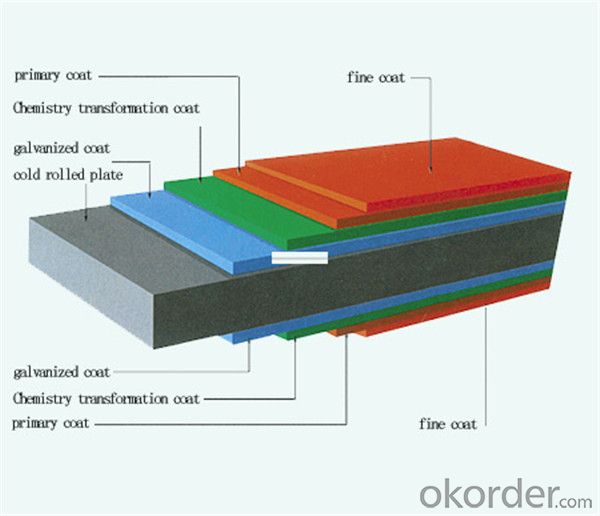

Brief of Product

Product Features

1 Extending service life of products:

Color coating is for protecting steel substrate and for promoting corrosion control effects. Subject to the environment, the different coating combination promotes environmental resisting functions (such as heat resistance, corrosion resistance, humidity resistance, bending resistance, weathering resistance, impact resistance, acid / alkali resistance, chemical resistance and pollution resistance) to offer ultra durability.

2 Better forming ability:

Coating Layer has good bending ability and in high speed forming, it maintains good forming ability and would not cracking or peel off. The coating could be adjusted to meet for different substrate general use, drawing, deep drawing or lock forming, structural use and other purposes.

3 ariable colors:

With different glosses and colors, it displays beautiful appearance that allow for new product designs, diversified creative elements and higher living quality.

Standard and Grade :

Pre-paint galvanized steel coil | ||||

ASTM A755M-03 | EN10169:2006 | JISG 3312-2012 | ||

Commercial quality | CS | DX51D+Z | CGCC | |

Structure steel | SS GRADE 230 | S220GD+Z | CGC340 | |

SS GRADE 255 | S250GD+Z | CGC400 | ||

SS GRADE 275 | S280GD+Z | CGC440 | ||

SS GRADE 340 | S320GD+Z | CGC490 | ||

SS GRADE550 | S350GD+Z | CGC570 | ||

S550GD+Z | ||||

Application :

Outdoor | Roof, roof structure, surface sheet of balcony, frame of window, door of garage, rolled shutter door, booth, Persian blinds, cabana, etc |

Indoor | Door, isolater, frame of door, light steel structure of house, home electronic appliances, ect. |

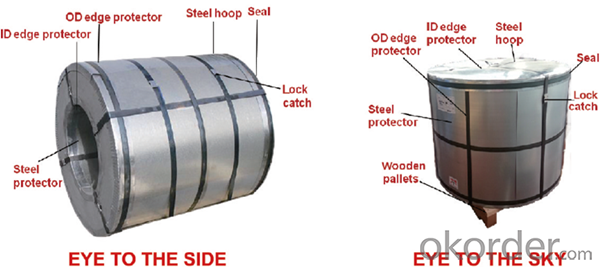

Packing:

Packaging Detail | The packing of coil consists of anti-damp paper ,PVC film ,hardboard paper , steel box , strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye of the side) or wooden pallets(eye of the sky) |

Delivery Time | within 30 days of receipt of LC original or prepayment |

Our service:

MOQ | FCL, 25 metric tons per 20GP, can be assorted with different sizes. |

LCL for trial order is acceptable. | |

Price Term | EX-WORK, FOB China Port, CNF, CIF |

Payment | T/T, 30% advanced payment before production and balance before shipment; OR Irrevocable L/C at sight. |

Delivery Time | within 30 days of receipt of LC original or prepayment |

Our Services

FAQ:

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link

from raw material to final product we have strict quality test;We resolutely put an end to

unqualified products flowing into the market. At the same time, we will provide necessary

follow-up service assurance.

4. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange

the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but

the shipment will depend on the vessel situation

- Q: I need to identify a metal. It is rusty so I suspect it is either iron or steel. Since they both have similar densities and are magnetic, how do I tell the difference betweeen steel and iron?

- Iron is a natural ore. Google: Iron ore, click on Mineral Information Institute - Iron Ore. Steel is a man-made material, consisting of iron. Google: Sir Henry Bessemer, inventor.

- Q: What are the common methods of packaging steel coils for international shipping?

- The common methods of packaging steel coils for international shipping include using wooden crates or pallets, securing the coils with metal or plastic strapping, using moisture-resistant packaging materials, such as plastic or shrink wrap, and adding dunnage or cushioning materials to prevent movement or damage during transit. Additionally, steel coils may be packed in containers or onto flat racks for optimal stability and protection.

- Q: What are the common coil weights available for steel coils?

- The available coil weights for steel coils vary depending on the specific application and industry requirements. However, the market offers a few standard coil weights. 1. Light coils: Industries such as automotive, construction, and appliance manufacturing prefer light coils weighing between 3 to 6 metric tons (6,000 to 13,000 pounds). These smaller and more manageable coil sizes are commonly used. 2. Medium coils: Industries like construction, infrastructure, and general manufacturing utilize medium coils weighing between 6 to 15 metric tons (13,000 to 33,000 pounds). 3. Heavy coils: Heavy industries such as shipbuilding, heavy machinery manufacturing, and infrastructure projects require heavy coils weighing over 15 metric tons (33,000 pounds), with some reaching 30 metric tons (66,000 pounds) or more. These coils provide the necessary strength for large steel components. It's important to understand that these weight ranges are flexible and subject to customer or industry specifications. Some manufacturers may even offer customized coil weights to meet specific project requirements. To determine the most suitable coil weight for a particular application, it is advised to consult with a steel supplier or manufacturer.

- Q: What are the benefits of using stainless steel coils?

- There are several benefits of using stainless steel coils. Firstly, stainless steel is highly resistant to corrosion and rust, making it ideal for applications in harsh environments or where exposure to moisture is likely. Secondly, stainless steel coils offer excellent heat resistance, making them suitable for high-temperature applications. Moreover, stainless steel coils are durable and have a long lifespan, reducing the need for frequent replacements. Additionally, stainless steel is easy to clean and maintain, making it a hygienic choice for industries such as food processing and medical equipment manufacturing. Lastly, stainless steel coils provide excellent strength and structural integrity, ensuring the reliability and efficiency of various industrial processes.

- Q: i currently have just steel guitar strings, not a fan they need replacing and i was wondering whats the difference between steel and bronze strings and or nickle strings?

- You may want to experiment with different alloys to find which sound best on your guitar...but if it's acoustic, you should be using bronze wound strings.

- Q: Theirs this two handed chinese sword on amazon with a forged combat steel blade and i was wandering if it means combat steel in the same sense that tempered carbon steel can be used?

- as has been said before it is a mystery steel that could mean anything honestly I am guessing closer to 1045 than the already mentioned 1095.... or just stainless steel of some variety tldr we all are telling the truth do not buy it

- Q: What are the safety precautions to be followed while handling steel coils?

- When handling steel coils, it is important to follow certain safety precautions to prevent accidents and injuries. Here are some safety precautions to be followed: 1. Personal Protective Equipment (PPE): Always wear appropriate PPE, such as safety glasses, gloves, steel-toed boots, and hard hats. These items will protect you from potential hazards like falling objects, sharp edges, and chemicals. 2. Proper Lifting Techniques: Use proper lifting techniques to prevent strains and back injuries. Lift with your legs, not your back, and avoid twisting or jerking motions while handling the coils. If the coils are too heavy or awkward to lift manually, use mechanical lifting equipment like forklifts or cranes. 3. Secure Storage: Store steel coils in a secure and stable manner to prevent them from falling or rolling over. Use proper racks, shelves, or storage containers designed specifically for steel coils. Ensure that the storage area is clean, organized, and free from obstructions. 4. Handling Tools: Use appropriate handling tools like coil hooks, lifting clamps, or coil tongs to securely grip the steel coils. Avoid using makeshift or improper tools, as they can cause the coils to slip, resulting in accidents. 5. Secure Transportation: When transporting steel coils, ensure they are properly secured on the truck or flatbed. Use appropriate tie-downs, straps, or chains to prevent the coils from shifting or falling during transit. Follow all transportation regulations and guidelines to ensure safe transportation. 6. Awareness of Surroundings: Be aware of your surroundings and the presence of other workers or equipment in the area. Maintain a safe distance from moving machinery, forklifts, or other vehicles to avoid collisions or accidents. 7. Hazard Communication: Ensure that all employees handling steel coils are trained on proper safety procedures and understand the potential hazards involved. Display safety signs or labels to indicate the presence of heavy loads or hazardous materials. 8. Regular Maintenance: Regularly inspect and maintain equipment, such as lifting devices or storage racks, to ensure they are in good working condition. Report any defects or malfunctions to the appropriate personnel for prompt repairs. By following these safety precautions, you can minimize the risk of accidents, injuries, and damage when handling steel coils. It is important to prioritize safety in order to protect yourself and your coworkers in the workplace.

- Q: What is the average thickness tolerance for steel coils?

- The average thickness tolerance for steel coils can vary depending on the specific industry and application. However, a common average thickness tolerance for steel coils is typically around ±0.005 to ±0.010 inches.

- Q: Ok.. I was wondering if it's possible for me to recycle baked bean cans (steel)? And if so in Western Australia (that's where I live)?I love baked beans... and I also like skateboarding, so I thought if I kept my baked bean cans, that I could get them recycled somewhere and turn it into something I could skate on (rail, etc.). I'm just curious to know if all this is possible...Cheers. :)

- Most baked beans are cooked with pork and include a piece in the can. Depending on what kind of vegetarian you are, you could eat them and simply remove the piece of pork, or, Bush's has vegetarian baked beans which are obviously cooked without the meat seasoning. They are very good, and of course beans are an excellent and needed source of protein in a vegetarian diet.

- Q: The knife will be large and thick. Like the Bowie knife Rambo uses in Rambo III. It doesn't need to be flexible or to hold the edge very well. But i need it to be exceptionally strong material and to stop corrosion at least decently. Is Damascus Steel good?Thank you, in advance.

- If it does not could desire to hold an part o.k. then 440 stainless could be your appropriate guess. I want severe carbon steel. yet they require alot of cleansing and oiling or they're going to rust.

Send your message to us

Color coated steel coil base material GL

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 31234 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords