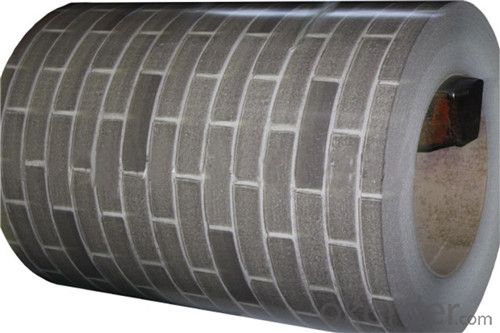

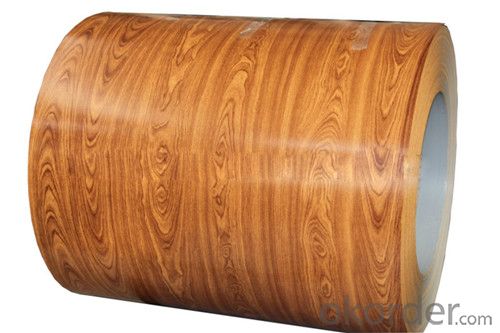

color coated Galvanized cold Rolled Steel coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

APPLICATION:

Construction:1) Outside: Workshop, agricultural warehouse, residential precast unit, corrugated roof, roller shutter door, rainwater drainage pipe, retailer booth

2) Inside: Door, doorcase, light steel roof structure, folding screen, elevator, stairway, vent gutter

Electrical appliance: Refrigerator, washer, switch cabinet, instrument cabinet, air conditioning, micro-wave oven, bread maker

Furniture: Central heating slice, lampshade, chifforobe, desk, bed, locker, bookshell

Carrying trade: Exterior decoration of auto and train, clapboard, container, isolation lairage, isolation board

Others: Writing panel, garbage can, billboard, timekeeper, typewriter, instrument panel, weight sensor, photographic equipment

| prime prepainted galvanized steel coil | |

| Thickness | 0.15-2.5 mm |

| Width | 350-1500 mm |

| Coil ID | 508mm/610mm |

| Standard | AISI, ASTM, BS, DIN, GB, JIS |

| Material | DX51D+Z, SGCC, DX51D+AZ,SPCC-1B |

| Zinc coating | 60-180g/M2 |

| Painting thickness | 20-25um |

| Colors | All Colors available. Color shades, Ral Color |

| End | Threading ,coupling and with plastic caps protected |

| Payment | TT ,L/C, Western Union |

| Packing | Standard seaworthy packing or as required |

| Market | Mild east, North/South America, Europe, Asia,Africa etc |

| Certificate | BV,SGS,MTC ,ISO9001:2000, |

- Q: I looking at replacing a few of the panels on my car with either Carbon Fiber or High Tensile Steel to shave off some weight and increase mpg and take some time off my quarter mile. Which is better: Carbon Fiber or High Tensile Steel?

- Steel is much cheaper to buy, but weighs more than the carbon fiber and is not as strong as a rule. To save weight on a race car go with carbon fiber. To save weight (money) on the wallet go with steel.

- Q: How are steel coils protected against scratches and damage?

- Steel coils are protected against scratches and damage through a variety of methods. One common method is the application of a protective coating or film on the surface of the coils. This coating acts as a barrier, preventing direct contact between the steel surface and any potential sources of scratches or damage. The protective coating can be made of materials like polyethylene, PVC, or other types of plastic that are resistant to abrasion and impact. Additionally, steel coils are often wrapped or packaged using materials such as paper, cardboard, or plastic. This wrapping provides an extra layer of protection against scratches and damage during storage, transportation, and handling. The wrapping material acts as a cushion, absorbing any potential impacts or friction that could lead to scratches. Furthermore, steel coils may be stored and transported in specially designed containers or pallets that are equipped with features to minimize the risk of damage. For instance, these containers or pallets may have padded interiors, secure fastenings, or dividers that keep the coils in place and prevent them from rubbing against each other. In some cases, steel coils are also stored or transported in a controlled environment to minimize the risk of damage. This can include temperature-controlled warehouses or shipping containers that help to prevent the formation of moisture, which can lead to corrosion or other types of damage. Overall, a combination of protective coatings, wrapping materials, specialized containers, and controlled environments is employed to ensure that steel coils are adequately protected against scratches and damage throughout their lifecycle.

- Q: How many pounds can steel lift?

- I think that you failed to put up a meaningful question. I suggest that you try again and seek help.

- Q: On how to reinforce steel coils in a container

- In the bottom and sides with a thick strip stuck, but also to ensure that the wood will not loosen down...... Rough steel rolls, I saw people loading and unloading on the docks, poked them directly with a small forklift truck, and then reinforced with wooden planks

- Q: How is the critical temperature of structural steel affected by fireproofing? What temperatures can fireproofed structural steel withstand?

- I didn't know they fire proofed steel. Usally they would just use a steel with a higher melting point.

- Q: What are the dimensions of steel coils used in the structural component industry?

- The dimensions of steel coils used in the structural component industry can vary depending on the specific application and requirements. However, common dimensions for steel coils in this industry typically range from 0.5 to 3.0 millimeters in thickness and 600 to 2000 millimeters in width. The length of the coils can vary but is often around 2000 to 2500 meters.

- Q: What are the main steel coil producing countries?

- The main steel coil producing countries are China, Japan, India, the United States, and Russia.

- Q: What are the different types of steel coil storage locations?

- There are various types of steel coil storage locations, including open yards, covered warehouses, coil racks, and specialized coil storage systems.

- Q: Can steel coils be bent or formed into different shapes?

- Steel coils have the capability to be bent or molded into diverse forms. Typically, steel coils are produced from flexible flat rolled steel, allowing for easy manipulation. The process of bending entails exerting force upon the steel coil, resulting in a transformation of shape and the adoption of different configurations. This can be accomplished through a variety of techniques, including cold or hot bending, as well as the utilization of specialized machinery such as a press brake. By skillfully applying the appropriate amount of force and heat, steel coils can be bent or molded into an extensive array of shapes, encompassing curves, angles, and intricate geometries. This adaptability in shaping steel coils renders them exceptionally versatile for an array of applications, spanning construction, manufacturing, automotive, and numerous other industries.

- Q: How are steel coils used in the manufacturing of crash structures?

- Steel coils are used in the manufacturing of crash structures as they provide strength, durability, and energy absorption capabilities. These coils are typically formed into various shapes and sizes to create components that reinforce the vehicle's body, such as side impact beams or front and rear crumple zones. The steel coils absorb and distribute the impact energy during a crash, helping to protect the occupants by minimizing the force transferred to the passenger compartment.

Send your message to us

color coated Galvanized cold Rolled Steel coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords