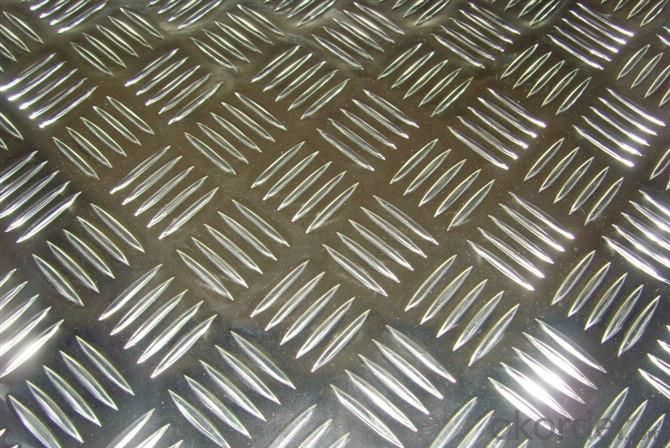

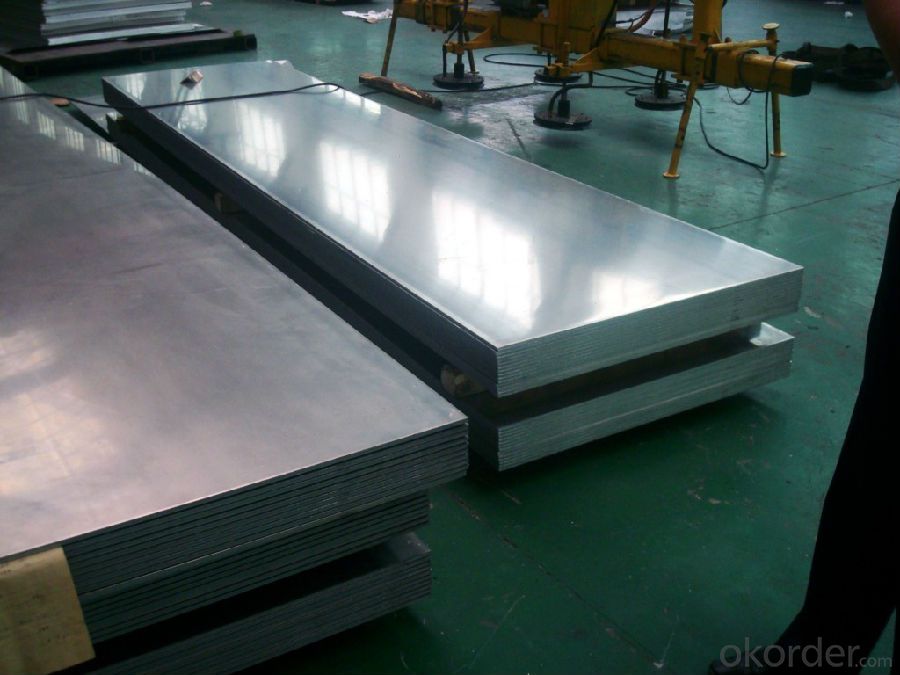

Stucco Embossed Color Coated Diamond Embossed Aluminum Sheet Coil Plate for Roofing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Color Coated Diamond Embossed Aluminum Sheet Coil Plate for Roofing

Description

Aluminium Sheet | ||||||

Alloy | Thickness(mm) | Width(mm) | Length(mm) | Temper | DC or CC | |

1050,1060,1070,1100,1235 | 0.2-4.0 | 400-1850 | 500-6000 | O,H12,H22,H14,H24,H16,H26,H18,H32 | DC, CC | |

4.0-150 | 1000-1900 | H112,H111 | DC | |||

3003,3004,3105 | 0.2-4.0 | 400-1850 | 500-6000 | O,H12,H22,H14,H24,H16,H26,H18,H32 | DC, CC | |

4.0-150 | 1000-1900 | H112,H111 | DC | |||

5052,5083,5754 | 0.2-4.0 | 400-1850 | 500-6000 | O,H12,H22,H14,H24,H16,H26,H18,H32 | DC | |

4.0-150 | 1000-1900 | H112, H111 | DC | |||

8011 | 0.08-0.20 | 400-1500 | 500-6000 | O,H12,H22,H14,H24,H16,H26,H18 | DC, CC | |

Packing | Export standard wooden packing | |||||

Application | Mainly in Construction , decoration, PCB materials, cover material, piping, refrigeration, air conditioner, automobile, etc. | |||||

MOQ | 5MT | |||||

Kind attention | Specifications can be customized as the customer’s requirements. | |||||

FAQ

Q: How can I request a product sample? A: The samples are free but freight should be collected. Please send sample list and courier account number by email.

Q: How can I request a product catalog? A: The hard copies of catalogs are free but freight should be collected. Please send courier account number by email. You are suggested to request a PDF catalog.

Q: Wha's your payment terms? A: One is T/T 30% before production and 70% against copy of B/L; the other is Irrevocable L/C 100% at sight.

Q: What's your trade terms? A: FOB, CNF(CFR), CIF, EXW.

Q: How long is the quality guarantee? A: All of our products have a period of quality guarantee since time of shipment. Please contact your salesman for more details, as different products enjoy different time of guarantee

- Q: What is the bending radius for aluminum sheets?

- The bending radius of aluminum sheets may vary depending on the sheet's thickness and alloy. In general, thinner sheets (around 1-3 mm) should have a bending radius of approximately 1.5 times their thickness. On the other hand, thicker sheets (over 3 mm) can increase the bending radius to around 2.5 times their thickness. Nevertheless, it's important to bear in mind that these are general guidelines and the bending radius may need to be adjusted according to the specific application and desired outcome. To obtain accurate bending radius information, it is always recommended to seek advice from a professional or consult the manufacturer's technical data sheets.

- Q: As for cast aluminum sheet or wrought one, which one has faster heat conduction?

- 1,duralumin: it's the alloy of aluminum, copper, magnesium, manganese and other metals. it's suitable for compacting by rolling, and it has a higher strength and hardness than common aluminum products. 2, aluminum: it contains many inpurities, is crisp and easy to be smashed.cast aluminum usually is secondary aluminum, and it is produced by remelting the collected old aluminum pots and spoons.3, wrought aluminum: it contains 98% aluminum and 2% or more inpurities, and is comparatively pure aluminum. its soft priority makes it suitable for being pressed into various shapes, aluminum pots,aluminum lunch box,aluminum sheets,aluminum wires,aluminum pipes are all made by wrought aluminum.you will know their defferences from their definition.

- Q: What are the different methods of punching aluminum sheets?

- There are several methods of punching aluminum sheets, including manual punching using handheld tools, mechanical punching using presses, and CNC punching using computer-controlled machines.

- Q: Is it possible to utilize aluminum sheets in a home renovation project?

- <p>Yes, you can use aluminum sheets for your home renovation project. Aluminum is a versatile material known for its strength, durability, and resistance to corrosion. It's commonly used for roofing, siding, and even for decorative purposes. Aluminum sheets are lightweight, easy to install, and can be painted or coated to match your home's aesthetic. They also offer good thermal performance and can be recycled, making them an environmentally friendly choice. However, it's important to consider the specific requirements of your project, such as the local climate, design preferences, and budget, to ensure aluminum is the best fit.</p>

- Q: This question asks for a comparison of aluminum sheets with other materials regarding their cost and performance.

- <p>Aluminum sheets are generally cost-effective and offer excellent performance compared to many other materials. They are lightweight, which reduces material and transportation costs. They also have high strength-to-weight ratios, making them durable and resistant to corrosion. In terms of performance, aluminum sheets are versatile, used in various industries such as construction, automotive, and aerospace. They conduct heat and electricity well, which is beneficial for applications requiring thermal or electrical conductivity. However, they may be more expensive than some plastics or cheaper metals like steel on a per-unit basis, but their lower weight and durability often offset this cost over time.</p>

- Q: Can aluminum sheets be used for outdoor applications?

- Certainly, outdoor applications can involve the utilization of aluminum sheets. Aluminum, being both resilient and resistant to corrosion, proves itself suitable for a diverse array of outdoor purposes. It is frequently employed in tasks such as roofing, siding, guttering, as well as outdoor signage. A distinguishing feature of aluminum sheets is their exceptional strength-to-weight ratio, rendering them perfect for situations where a material that is simultaneously lightweight and robust is imperative. Moreover, aluminum possesses the inherent ability to generate a safeguarding oxide layer, thereby shielding itself from external elements. Consequently, it emerges as a dependable option for outdoor settings.

- Q: Can aluminum sheets be bent or formed?

- Indeed, it is possible to bend or shape aluminum sheets. Aluminum, being a remarkably malleable and ductile metal, can be effortlessly molded or bent without fracturing. This attribute renders it a favored option for a wide range of purposes, including the production of automotive components, aircraft structures, and household products. Diverse techniques, such as press braking, roll bending, and stretch forming, can be employed to bend or shape aluminum sheets. By utilizing these methodologies, the aluminum sheets can be formed into diverse angles or curves to fulfill precise design prerequisites.

- Q: How many square meters does the aluminum plate engrave?

- The price of aluminum sheet is calculated according to the price of aluminum ingot + processing fee (aluminum plate state), and the specific price is also different according to the size and size of aluminum sheet. If you have any questions, please ask, thank you.

- Q: Are aluminum sheets suitable for aviation applications?

- Yes, aluminum sheets are suitable for aviation applications. Aluminum is widely used in the aviation industry due to its lightweight, high strength-to-weight ratio, and corrosion resistance properties. It is used in the construction of aircrafts, including the fuselage, wings, and structural components. Aluminum sheets provide structural integrity, while also reducing the overall weight of the aircraft, which improves fuel efficiency and performance. Additionally, aluminum sheets can be easily formed and fabricated, making them versatile for various aviation applications.

- Q: What are the common thicknesses of aluminum sheets used in construction?

- Depending on the specific application and requirements, the thicknesses of aluminum sheets commonly used in construction can vary. Some commonly employed thicknesses are 0.032 inches (0.81mm), 0.040 inches (1.02mm), 0.050 inches (1.27mm), and 0.063 inches (1.60mm). These thicknesses are frequently utilized for architectural purposes, including wall panels, roofing, and siding. Thicker aluminum sheets, such as 0.080 inches (2.03mm) and 0.125 inches (3.18mm), find use in heavier construction applications like structural components, support beams, and decking. It is worth noting that these thicknesses merely serve as examples and may vary depending on the specific project requirements and engineering specifications.

Send your message to us

Stucco Embossed Color Coated Diamond Embossed Aluminum Sheet Coil Plate for Roofing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords