4 X 8 Sheets of Aluminum - Color Coated Aluminum Coils for Outer Decoration Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Color Coated Aluminium Coils for Outer Decoration Wall

Color Coated Aluminium Coils for Outer Decoration Wall for Composite Panel is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Color Coated Aluminium Coils for Outer Decoration Wall

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

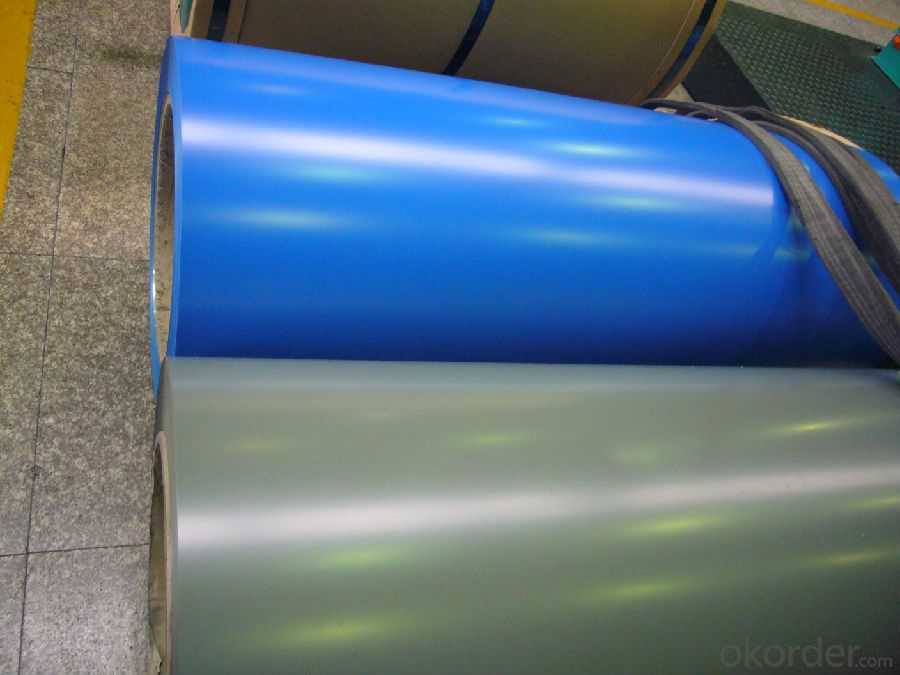

3. Image of Color Coated Aluminium Coils for Outer Decoration Wall

4. Product Specification of Domestic Color Coated Aluminium Coils for Wall Curtain

| Alloy | Temper | Thickness | Width | Weight |

| AA3003 | H14 | 0.2MM-3MM | 1000MM-1800MM | 2 TONS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: What is the tensile strength of aluminum sheets?

- The tensile strength of aluminum sheets can vary depending on the specific alloy and temper, but generally ranges from 20,000 to 45,000 pounds per square inch (psi).

- Q: How would you write the formula for aluminum sulfate and calcium chloride?

- AlSO4 CaCl

- Q: When zinc dust and sulfur dust are combined in certain proportional ratios and ignited, a violent exothermic reaction occurs. Because the reaction only depends on two components; zinc and sulfur, but not oxygen, the reaction has all of the components that it needs within the mixture. The same is also true for a mixture of magnesium and sulfur.However, the same reaction does not occur with iron and sulfur. Instead, the mixture reacts slowly over a period of a few minutes rather than flashing to smoke in less than a second. Now for my questions:1: If aluminum and sulfur were combined in the same proportional ratios as the zinc and the magnesium mixtures were, would the reaction be as fast as the zinc and the magnesium mixtures? Why or why not?2: What properties of the different metals used in these mixtures makes them behave so differently?

- 1. This depends on the aluminium particle size and it's quality as Al is normally coated with an oxide layer that protects the Al metal underneath. Assuming that the Al powder was good stuff, it should react as violently as the Zn and Mg mixtures. Why .. because it is a very reactive metal ... see further info below. However I needed tried it. 2. The difference is really about the reactivity. Iron, although a reactive metal, is far less reactive than Mg,Al, and Zn. I have tried the zinc and sulphur a number of times and it is really quite violent. With a fair quantityof reactants in the lab it produced an excellent mushroom smoke cloud. I've also seen the Al reactivity demonstrated by a mad Chemistry prof from Nottingham University. He mixed Al powder into a paste with liquid oxygen and ignited it! Wow ... what a reaction.I shall never forget it although it was about 35 years ago!

- Q: What is the reflectivity of 101 aluminum sheets?

- The reflectivity of 101 aluminum sheets can vary depending on a few factors such as the surface finish, thickness, and any additional coatings or treatments applied to the sheets. Generally, aluminum has a high reflectivity, especially in the visible light spectrum. It can reflect around 80% to 90% of visible light, making it a popular material for reflective surfaces, mirrors, and various lighting applications. However, it is essential to note that the exact reflectivity of 101 aluminum sheets may differ based on specific manufacturing processes or variations in the material properties.

- Q: What are the different surface finishes for aluminum sheets in the aerospace industry?

- Some of the different surface finishes for aluminum sheets in the aerospace industry include mill finish, anodized finish, brushed finish, and painted finish. These finishes are applied to enhance the appearance, durability, corrosion resistance, and overall performance of the aluminum sheets in aerospace applications.

- Q: 3003H24 alloy aluminum plate refers to what kind of aluminum plate?

- 3003H241, the first to 3 words led by the expression is: manganese as the main alloying elements of aluminum alloy;2, second, 0 words indicate that the aluminum alloy, its impurity limit content without special control;3, third, fourth digit 03 indicates modification alloy, not too much actual connotation;4. H means products that increase strength by working hardening;5, 24 in 2 said the work hardening and incomplete annealing state (i.e. the degree of work hardening than product requirements after incomplete annealing strength is reduced to the specified index products) 4 means O is intermediate state to the 8 state that value.

- Q: What are the potential safety issues that may arise from the use of aluminum sheets?

- <p>Aluminum sheets are generally safe to use in most applications. However, there are a few safety concerns to consider. First, aluminum can be a skin irritant for some individuals, so it's important to wear protective gloves when handling. Second, aluminum dust, when inhaled, can cause respiratory issues. Proper ventilation should be maintained during cutting or grinding operations. Lastly, aluminum can conduct electricity, so it should not be used in electrical applications without proper insulation. Always follow safety guidelines and use protective equipment when working with aluminum sheets to minimize these risks.</p>

- Q: Can aluminum sheets be used for industrial shelving?

- Certainly, industrial shelving can indeed make use of aluminum sheets. Aluminum, being a material that is lightweight and durable, offers numerous benefits for industrial shelving applications. It possesses resistance against corrosion, making it suitable for environments that face exposure to moisture or harsh chemicals. Moreover, the strength-to-weight ratio of aluminum proves advantageous, enabling the creation of robust shelves capable of supporting heavy loads while remaining relatively light in weight. Furthermore, aluminum is low-maintenance as it does not necessitate painting or sealing like other metals. Consequently, aluminum sheets are an incredibly practical option for industrial shelving due to their durability, resistance to corrosion, and lightweight characteristics.

- Q: Is aluminum sheet corrosion-resistant?

- Yes, aluminum sheet is corrosion-resistant due to its natural oxide layer that forms on its surface, protecting it from corrosion and making it suitable for various applications in industries such as construction, automotive, and aerospace.

- Q: Is it possible to use aluminum sheets for indoor purposes?

- <p>Yes, aluminum sheets can be used for indoor applications. They are commonly used in interior design for their durability, lightweight, and resistance to corrosion. Aluminum sheets are often utilized in the construction of furniture, decorative panels, and even as a material for interior walls and ceilings. Their ease of maintenance and ability to be recycled make them an environmentally friendly option for indoor use.</p>

Send your message to us

4 X 8 Sheets of Aluminum - Color Coated Aluminum Coils for Outer Decoration Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords