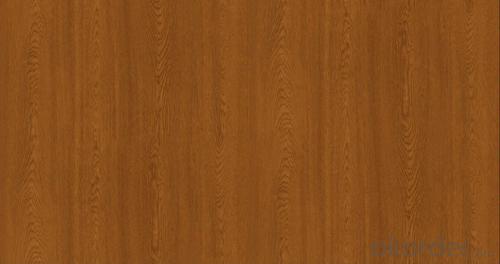

color bond surface coating steel plate--XY015

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Color bond surface coating steel plate :

2.More than ten years experiences, the products are sold to the domestic city and some international cities we strivc to develop production of color coating steel plate the plating (aluminum )zinc steel. Coil cheickness between 0.6mm and 1.5mm and the width from 600mm to 1250mm and a variety of high durability of color coating steel plate.

3.The company has multiple layer patterns for customers to choose The company provides products deep processing services ,meet the various needs of customers on board specifications All of out products comply with international quality standards and are greatly appreciated in a variety of different markets throughout the world.

4 If you ate interested in any of our products or would like to discuss a custom order please feel free to contact us we are looking forward to forming successful business relationships with new clients around the world in the near future.

5.We can design the color and thickness according to customers' requirements. The delivery time is only 30 day after you confirm the order.

- Q: What are the safety considerations when handling steel sheets?

- When handling steel sheets, there are several safety considerations to keep in mind. Firstly, it is important to wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and steel-toed boots to protect against potential injuries. Secondly, steel sheets can be heavy and cumbersome, so it is crucial to use proper lifting techniques and equipment to avoid strains or muscle injuries. Additionally, sharp edges or corners on steel sheets can pose a risk of cuts or punctures, so caution should be exercised when handling them. Lastly, steel sheets can be slippery when wet or oily, so it is essential to maintain a clean and dry working area to prevent slips and falls. Overall, awareness, caution, and adherence to safety protocols are key when handling steel sheets to ensure the well-being of individuals involved.

- Q: Are steel sheets suitable for swimming pool construction?

- Yes, steel sheets are suitable for swimming pool construction. Steel sheets are known for their strength and durability, making them an excellent choice for building swimming pools. They provide a stable and sturdy structure that can withstand the weight of the water and the pressure exerted on the pool walls. Additionally, steel sheets can be easily molded and welded into various shapes and sizes, allowing for customization and flexibility in pool design. Moreover, steel is resistant to corrosion, which is crucial for maintaining the integrity of the pool over time, especially when exposed to chlorinated water. Therefore, steel sheets are a reliable and popular option for swimming pool construction.

- Q: How do steel sheets perform in terms of corrosion resistance?

- Steel sheets, particularly those that are coated or galvanized, exhibit excellent corrosion resistance due to their inherent properties and protective coatings. The corrosion resistance of steel sheets can be attributed to the presence of iron oxide (rust), which forms a protective layer over the steel, preventing further corrosion. Additionally, various coatings like zinc or paint can be applied to further enhance their resistance against corrosion, making steel sheets a reliable choice for various applications.

- Q: What are the common applications of steel sheets?

- Steel sheets have a wide range of applications in various industries such as construction, automotive, manufacturing, and aerospace. They are commonly used for building structures, roofing, siding, and fencing in the construction industry. In automotive manufacturing, steel sheets are utilized for body panels, chassis, and various components due to their strength and durability. Additionally, steel sheets are widely employed in the manufacturing sector for fabrication, stamping, and forming processes. Lastly, the aerospace industry relies on steel sheets for aircraft structures, engine components, and other critical parts due to their high strength-to-weight ratio and resistance to extreme temperatures.

- Q: Can steel sheets be welded together?

- Yes, steel sheets can be welded together. Welding is a common method used to join steel sheets by melting the edges and fusing them together to create a strong and durable bond.

- Q: What industries commonly use steel sheets?

- The industries that commonly use steel sheets include construction, automotive, manufacturing, aerospace, and shipbuilding.

- Q: Can steel sheets be used for manufacturing kitchen utensils?

- Yes, steel sheets can be used for manufacturing kitchen utensils. Steel is a commonly used material in the manufacturing of kitchen utensils due to its durability, heat resistance, and ease of cleaning. Steel sheets can be shaped and formed into various utensil designs, making them suitable for cooking and food preparation purposes.

- Q: Are the steel sheets corrosion-resistant?

- Yes, steel sheets are corrosion-resistant due to their composition and protective coatings.

- Q: What are the fire resistance properties of steel sheets?

- Steel sheets have excellent fire resistance properties due to their high melting point and low thermal conductivity. They do not catch fire or contribute to the spread of flames, making them a reliable choice for construction in fire-prone areas. Additionally, steel maintains its structural integrity even at high temperatures, providing enhanced protection and stability during a fire incident.

- Q: What is the typical price difference between galvanized and non-galvanized steel sheets?

- The typical price difference between galvanized and non-galvanized steel sheets can vary depending on factors such as size, thickness, and market conditions. However, in general, galvanized steel sheets tend to be more expensive than non-galvanized ones, typically costing around 10-20% more.

Send your message to us

color bond surface coating steel plate--XY015

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords