Cold Rolled Steel Strip for Construction Material

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 52733 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Cold rolled sheet steel products are used in a wide variety of end applications such as appliances, automobiles- exposed as well as unexposed parts, electric motors, plumbing fixtures, drum manufacturing, shelving, furniture, doors, toolboxes, tubing products, unexposed construction products, as well as many other areas of manufacturing.

It is suited to formation by bending or drawing, which enables complex parts to be produced in good repeatable conditions and

intended for indoor use.

These cold rolled steel coil/sheet grades have excellent formability, which facilitates cold forming operations, and are ideal for deep

drawing.

Our range of steels for cold forming offer excellent forming performance, due to the low scattering of their chemical composition

and their mechanical properties, which guarantees processing consistency.

Standard and Grade :

JIS G3141-2005 | EN10130-2006 | ASTM A1008-12a | ||

Commercial quality | SPCC | DC01 | CS Type A/B/C | |

Drawing quality | SPCD | DC03 | DS Type A/B | |

Deep drawing quality | SPCE SPCF(non aging) | DC04 | DDS | |

Extra deep drawing quality | SPCG(non aging) | DC05/06 | EDDS | |

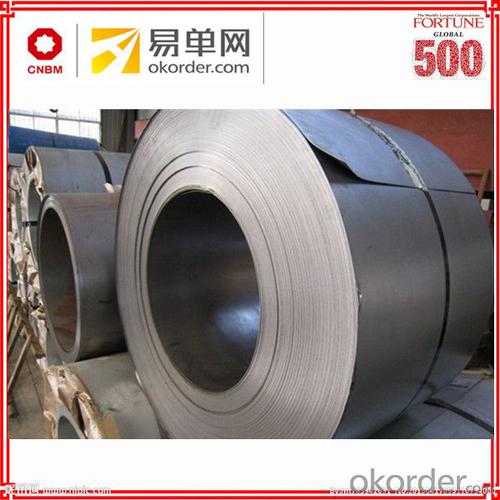

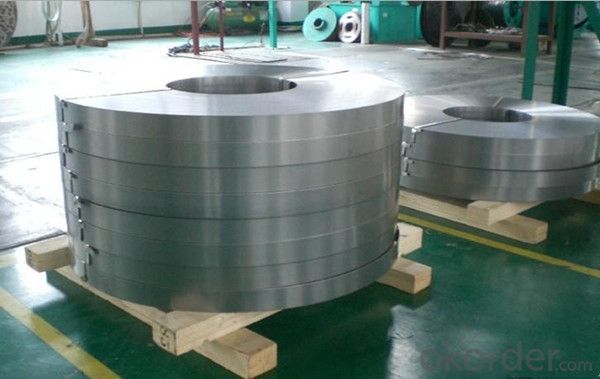

Pictures

Application :

Automobile Industry, White Goods, Home Applicances, Oil & Air filters, semi product for coating with enamel or zinc, construction &

building sector, air-conditioning, furniture, radiators, tubes, profiles, mechanical construction, shelving, containers, drums

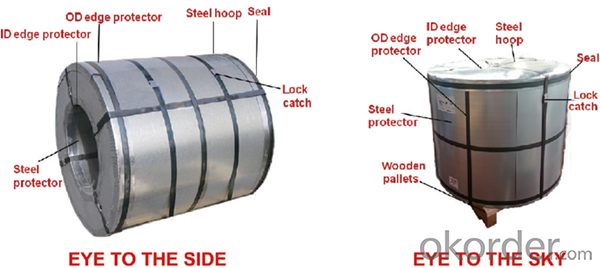

Packing:

Packaging Detail | The packing of coil consists of anti-damp paper, PVC film, hardboard paper, steel box, strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye of the side) or wooden pallets(eye of the sky) |

Delivery Time | within 30 days of receipt of LC original or prepayment |

- Q: How are steel coils used in the manufacturing of telecommunications equipment?

- Steel coils are used in the manufacturing of telecommunications equipment as they are commonly used as a raw material for various components, such as enclosures, cabinets, and brackets. The coils are processed and shaped to create the necessary parts that provide structural support, protection, and stability to the telecommunications equipment.

- Q: What are the dimensions of steel coils?

- The dimensions of steel coils vary depending on factors such as the specific type of steel, the intended use, and industry standards. Generally, steel coils can range in width from a few inches to several feet, with thicknesses typically ranging from a fraction of an inch to several millimeters. The inner diameter of a steel coil can also vary, with common sizes being 20 inches and 24 inches. Ultimately, the dimensions of steel coils are determined by the specific needs and requirements of the end user.

- Q: What is the maximum width of steel coils?

- The maximum width of steel coils can vary depending on the specific manufacturing processes and equipment capabilities, but it is typically around 72 inches (182.88 cm).

- Q: What is the minimum order quantity for steel coils?

- The minimum order quantity for steel coils can vary depending on the supplier and specific product. It is recommended to contact the supplier directly to inquire about their minimum order requirements for steel coils.

- Q: How do steel coils contribute to the agricultural sector?

- The agricultural sector benefits greatly from the use of steel coils in various ways. To begin with, these coils are instrumental in the production of agricultural machinery and equipment such as tractors, harvesters, and irrigation systems. These machines are indispensable for carrying out farming operations efficiently, thereby helping farmers increase productivity and cut down on labor costs. The robustness and durability of steel coils ensure the machinery's ability to endure the harsh conditions of the agricultural environment. Furthermore, steel coils find application in the construction of storage facilities and warehouses for agricultural products. To safeguard crops from damage, these structures must be strong and resistant to external elements. Steel coils provide the required strength and stability for the construction of such storage facilities, thereby ensuring the secure storage of agricultural produce. In addition, steel coils are employed in the fabrication of fencing and other agricultural infrastructure. Fencing is of utmost importance in protecting crops from animals and trespassing. Steel coils serve as a robust material for fencing, guaranteeing the security and protection of agricultural lands. Moreover, steel coils are utilized in the manufacture of irrigation pipes and systems. Efficient irrigation is crucial for the growth and yield of crops, particularly in areas with limited water resources. Steel coils are used to create pipes capable of withstanding high pressure and resistant to corrosion, thereby ensuring the effective distribution of water throughout agricultural fields. In conclusion, steel coils play a vital role in the agricultural sector, providing the necessary materials for manufacturing machinery, constructing storage facilities, fencing, and irrigation systems. The strength, durability, and resistance to harsh conditions make steel coils an essential component in enhancing agricultural productivity, protecting crops, and ensuring efficient farming practices.

- Q: How do steel coils contribute to the marine industry?

- Steel coils contribute to the marine industry by being used in the construction of ships and offshore structures. They are essential for manufacturing various components, such as hulls, decks, beams, and structural supports. Steel coils provide strength, durability, and corrosion resistance, ensuring the longevity and safety of marine vessels and infrastructure. Additionally, steel coils are used for the production of marine equipment, including cranes, winches, and anchor chains, further enhancing the efficiency and functionality of the marine industry.

- Q: How are steel coils coated for color and aesthetics?

- Steel coils are coated for color and aesthetics through a process called coil coating. This involves applying a layer of paint or coating onto the steel coil surfaces, which is then cured and bonded to create a uniform and durable finish. This coating process not only enhances the appearance of the steel coils but also provides protection against corrosion and other environmental factors, making them suitable for various applications in industries such as construction and automotive.

- Q: What are the common methods of slitting or shearing steel coils?

- The common methods of slitting or shearing steel coils include rotary shear, guillotine shear, and laser cutting.

- Q: i am working a client.my vendor specified in pipe specification pipe line class as MS1 (code for Mild steel)but assigned material to this code is cs smls astm A 106B.my question is any difference between CS and MS material?pls suggest me

- CS is a noxious gas that I have tasted. If it is spec mild steel then do so.

- Q: Are steel coils used in the oil and gas industry?

- Yes, steel coils are commonly used in the oil and gas industry for various applications such as pipeline construction, storage tanks, and drilling equipment. The strength, durability, and corrosion resistance of steel make it an ideal material for handling the demanding conditions in this industry.

Send your message to us

Cold Rolled Steel Strip for Construction Material

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 52733 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords