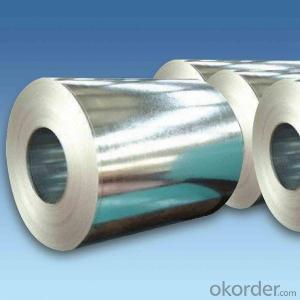

Cold Rolled Steel Coils 2B Hot Rolled Stainless Steel Coils NO.1 Finish

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products Description for Stainless Steel Coils/Sheets:

Product | stainless steel coils/plates/sheets | ||

Discharge Port | Any Port, China | ||

Size | Coils | Cold Rolled: | Thickness0.3-8mm,Width:280-2100mm |

Hot Rolled : | Thickness3-14mm,Width:650-2100mm | ||

Plates | Thickness2-80mm,Width:1500-3000mm | ||

Coil Weight | About 20 Tons | ||

Grade | 201,202,304/304L/304H,316/316L/316H,321/H,310S,409/L,430 etc. | ||

Technique | Hot Rolled/Cold Rolled | ||

Finish | 2B, BA, 2D, No1, No2, No4,NO.8,SB etc | ||

Edge | Mill Edge / Slitting Edge | ||

Package | In bundles, or as customer's requirement | ||

Place of Origin | Made in China | ||

MOQ | 20 Tons | ||

Packaging & Delivery for Stainless Steel Coils/Sheets:

Packaging Detail Standard export packing or following customer's demand

Delivery Time: Within 30-40 days after deposit or according to the order quantity

Detail picture for Stainless Steel Coils/Sheets

Application for Stainless Steel Coils/Sheets:

Boiler heat exchanger, machinery andpetroleum ,chemical industries, hardware fields,Food industry,construction material,kitchen utensils, building construction, medical equipment,chemical tank, pipe etc

FAQ for Stainless Steel Coils/Sheets:

Q:How to order?

A: Please send us your purchase order by email or fax .or you can ask us to send you a proforma invoice for your order .We need to know the following information for your order.

1) Shipping information-company name, street address, phone number, fax number, destination sea port

2) Product information – Quantity, Specification (steel type, thickness, width, surface finish)

3) Delivery time required

4) Forwarder's contact details if there's any in China

FAQ for Stainless Steel Coils/Sheets:

Q:What are the advantages of your company ?

A: We have many professionals, technical personnel, more competitive prices and best after-dales service than other stainless steel companies.

Q:Can you arrange the shipment ?

A: Sure we can help you with the shipment. We have forwarders who have cooperated with us for many years.

- Q: Can stainless steel sheets be used for solar water heaters?

- Yes, stainless steel sheets can be used for solar water heaters. Stainless steel is a durable and corrosion-resistant material, making it suitable for withstanding the harsh conditions of a solar water heating system. It can effectively absorb and retain heat, making it a good choice for the absorber plate in a solar collector. Stainless steel sheets also have excellent thermal conductivity, allowing for efficient heat transfer to the water. Additionally, stainless steel is a sustainable and environmentally friendly choice, as it is recyclable and has a long lifespan.

- Q: What is the flatness tolerance for stainless steel sheets?

- The specific grade and thickness of a stainless steel sheet can cause variations in its flatness tolerance. Typically, the flatness tolerance is defined as the maximum deviation from a completely flat surface. For stainless steel sheets, the accepted industry standard usually sets this tolerance at around 0.003 inches per linear foot. Nevertheless, it is crucial to acknowledge that various industries or applications may have their own unique flatness tolerance criteria. Consequently, it is always wise to refer to the relevant standards or specifications for the specific stainless steel sheet in question to ascertain the suitable flatness tolerance.

- Q: What are the different types of stainless steel sheet surface textures for decorative purposes?

- There are several types of stainless steel sheet surface textures commonly used for decorative purposes. These include brushed, mirrored, embossed, etched, and patterned surfaces. Each texture offers a unique aesthetic appeal and can be chosen based on the desired decorative effect.

- Q: What are the different edge finishes available for stainless steel sheets?

- There are several different edge finishes available for stainless steel sheets, each with its own unique characteristics and applications. 1. Mill Edge: This is the original edge produced during the rolling process at the mill. It has a slightly rough appearance and may contain mill scale or imperfections. Mill edge is suitable for applications where aesthetics are not a major concern, such as industrial or structural use. 2. Sheared Edge: This edge is obtained by shearing or cutting the stainless steel sheet to size. It has a straight, clean-cut appearance and is commonly used in applications where a smooth edge is desired, such as architectural or decorative purposes. 3. Deburred Edge: After the shearing process, the edges of the stainless steel sheet can be deburred to remove any sharp or rough edges. This creates a smooth and safe edge, making it suitable for applications where safety is a concern, such as food processing or medical equipment. 4. Rolled Edge: This edge finish is achieved by rolling the stainless steel sheet, which creates a rounded or curved edge. Rolled edges are often used in applications where safety is important, as they eliminate sharp corners and edges, reducing the risk of injury. 5. Beveled Edge: A beveled edge is created by cutting or grinding an angle onto the edge of the stainless steel sheet. This edge finish is commonly used in architectural or decorative applications, as it offers a stylish and visually appealing appearance. 6. Polished Edge: This edge finish involves polishing the edge of the stainless steel sheet to a smooth and reflective surface. Polished edges are often used in high-end architectural or decorative applications, as they enhance the overall aesthetic appeal of the stainless steel sheet. It is important to choose the appropriate edge finish based on the specific requirements of your application, taking into consideration factors such as aesthetics, functionality, and safety.

- Q: Can stainless steel sheets be used for athletic equipment?

- Indeed, athletic equipment can make use of stainless steel sheets. Renowned for their durability, resistance to corrosion, and strength, stainless steel proves to be the perfect material for myriad athletic equipment purposes. Gym equipment, like weightlifting bars, dumbbells, and exercise benches, regularly employs stainless steel in its construction. Moreover, basketball hoops, soccer goalposts, and other outdoor sports equipment rely on stainless steel sheets for their ability to endure harsh weather conditions. Furthermore, stainless steel sheets offer versatility by allowing customization and fabrication into a range of shapes and sizes, catering to diverse athletic equipment requirements.

- Q: What is the elongation percentage of stainless steel sheets?

- The elongation percentage of stainless steel sheets can vary depending on the specific grade and thickness of the material. Generally, stainless steel sheets have a moderate elongation percentage, typically ranging from 40% to 60%. However, certain grades of stainless steel with higher nickel content, such as austenitic stainless steel, can exhibit greater elongation percentages, often exceeding 60%. It is important to note that elongation percentage is a measure of the material's ability to deform plastically before fracturing, indicating its ductility.

- Q: Can stainless steel sheets be used for architectural façades?

- Yes, stainless steel sheets can be used for architectural façades. Stainless steel is a durable and versatile material that offers many advantages for façade applications. It is resistant to corrosion, weathering, and staining, making it an ideal choice for exterior use. Stainless steel sheets can be fabricated into various shapes and sizes, allowing for a wide range of design options. Additionally, stainless steel can be finished in different ways, such as brushed, polished, or colored, providing further aesthetic possibilities. Its strength and rigidity also make it suitable for large-scale installations. Overall, stainless steel sheets offer durability, aesthetic appeal, and design flexibility, making them a popular choice for architectural façades.

- Q: Are stainless steel sheets safe for medical applications?

- Yes, stainless steel sheets are safe for medical applications. They are widely used in the medical industry due to their excellent corrosion resistance, biocompatibility, and durability. Stainless steel is easy to clean, sterilize, and maintain, making it suitable for surgical instruments, medical devices, and equipment used in healthcare settings.

- Q: What are the common grades of stainless steel sheets used in construction?

- The common grades of stainless steel sheets used in construction include 304, 316, and 430.

- Q: What's the difference between galvanized steel and stainless steel?

- Galvanized steel sheet is to prevent the corrosion of steel plate surface, and prolong its service life, the surface of the steel plate is coated with a layer of metal zinc, this kind of zinc coated steel sheet is called galvanized sheet.

Send your message to us

Cold Rolled Steel Coils 2B Hot Rolled Stainless Steel Coils NO.1 Finish

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 28 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords