Hot Rolled Stainless Coils,Cold Rolled Stainless Coils,NO.1 Finishe,NO.2B Finish Steel Coils

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 18 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Products Description

Product | stainless steel coils/plates/sheets | ||

Discharge Port | Any Port, China | ||

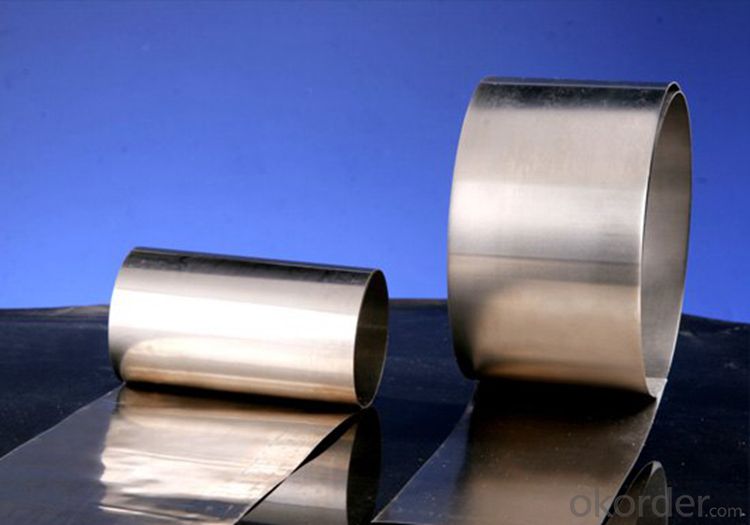

Size | Coils | Cold Rolled: | Thickness0.3-8mm,Width:280-2100mm |

Hot Rolled : | Thickness3-14mm,Width:650-2100mm | ||

Plates | Thickness2-80mm,Width:1500-3000mm | ||

Coil Weight | About 20 Tons | ||

Grade | 201,202,304/304L/304H,316/316L/316H,321/H,310S,409/L,430 etc. | ||

Technique | Hot Rolled/Cold Rolled | ||

Finish | 2B, BA, 2D, No1, No2, No4,NO.8,SB etc | ||

Edge | Mill Edge / Slitting Edge | ||

Package | In bundles, or as customer's requirement | ||

Place of Origin | Made in China | ||

MOQ | 20 Tons | ||

Payment Terms | 100% LC at sight,or 30%TT in advance, balance against B/L copy | ||

Delivery Time | With 30-40 days after deposit | ||

Packaging & Delivery

Packaging Detail | Standard export packing or following customer's demand |

Delivery Time | Within 30-40 days after deposit or according to the order quantity |

Detail picture of Products:

Application:

Finish | Definition | Application |

2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils. |

BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction. |

NO.3 | Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. | Kitchen utensils, Building construction. |

NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment. |

NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical tank, pipe. |

FAQ

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: Could you send me sample?

A: We can supply you with the sample for free, but the delivery charges will be covered by customers.

- Q:Can stainless steel sheets be used for decorative elevator doors or panels?

- Yes, stainless steel sheets can be used for decorative elevator doors or panels. Stainless steel is a versatile material that offers a polished and modern appearance, making it a popular choice for decorative applications. It is known for its durability, resistance to corrosion, and easy maintenance, making it suitable for high-traffic areas like elevator doors and panels. Additionally, stainless steel sheets can be customized with various finishes, patterns, and textures, allowing for endless design possibilities. Whether it's a sleek and minimalist look or a more intricate and decorative design, stainless steel sheets can enhance the aesthetics of elevator doors and panels while providing long-lasting functionality.

- Q:What are the benefits of using brushed stainless steel sheets?

- Using brushed stainless steel sheets has several advantages. To begin with, their sleek and attractive appearance makes them a popular choice for appliances, countertops, and backsplashes. The brushed finish adds a unique texture and matte appearance, bringing sophistication to any space. Additionally, brushed stainless steel sheets are highly durable and resistant to corrosion, making them suitable for indoor and outdoor use. They can withstand harsh conditions such as chemicals, moisture, and extreme temperatures. Moreover, their brushed finish helps to hide fingerprints, smudges, and scratches, making them easy to clean and maintain. Furthermore, brushed stainless steel sheets are hygienic and inhibit bacteria growth, making them ideal for the food and medical industries. Their smooth surface allows for easy cleaning and disinfection, ensuring a safe and sanitary environment. Moreover, these sheets offer excellent longevity and are a cost-effective investment. They resist wear and tear, maintaining their appearance for many years without the need for replacement. Lastly, brushed stainless steel sheets are versatile and can be customized to fit different design preferences. They can be easily cut, shaped, and formed into various sizes and shapes, allowing for endless design possibilities. Whether you prefer a modern, industrial look or a more traditional and elegant style, brushed stainless steel sheets can be tailored to meet your specific needs. In conclusion, the use of brushed stainless steel sheets offers benefits such as an attractive appearance, durability, corrosion resistance, hygienic properties, longevity, and versatility. Whether used in residential, commercial, or industrial settings, these sheets provide a wide range of advantages, making them a popular choice for various applications.

- Q:Can stainless steel sheets be used for elevator mirror panels?

- Yes, stainless steel sheets can be used for elevator mirror panels. Stainless steel is a durable and corrosion-resistant material that is commonly used in elevator design and construction. It is also highly reflective, making it an ideal choice for mirror panels. Stainless steel mirror panels not only provide a sleek and modern aesthetic to elevators but also offer excellent durability and ease of maintenance. Additionally, stainless steel can withstand the wear and tear of constant use, making it a reliable and long-lasting material for elevator mirror panels.

- Q:How do you remove stains or marks from stainless steel sheets?

- To effectively eliminate stains or marks from stainless steel sheets, follow these step-by-step instructions: 1. Begin by identifying the specific type of stain or mark present on the stainless steel sheet. Common examples include water spots, fingerprints, grease, or rust. 2. For general cleaning purposes, utilize a soft cloth or sponge soaked in warm water and mild dish soap. Gently wipe the stainless steel surface, ensuring to follow the grain to prevent scratching. Thoroughly rinse with clean water and dry using a soft cloth. 3. To tackle more stubborn stains or marks, create a paste by combining baking soda and water. Apply the paste to the affected area and gently rub it in using a soft cloth or sponge. Rinse off the paste with warm water and dry using a soft cloth. 4. For persistent grease stains, concoct a mixture of vinegar and water. Apply the vinegar solution to the stain and allow it to sit for a few minutes. Tenderly scrub the area with a soft cloth or sponge, following the grain of the stainless steel. Rinse thoroughly with clean water and dry. 5. In the case of rust stains, employ a mixture of lemon juice and cream of tartar. Apply the mixture to the stain and let it sit for a few minutes. Gently scrub the area with a soft cloth or sponge, following the grain. Rinse thoroughly with clean water and dry. 6. If stubborn stains persist despite the previous methods, resort to a stainless steel cleaner specifically designed for stain and mark removal. Adhere to the instructions provided with the cleaner and ensure thorough rinsing and drying of the surface afterward. Always remember to test any cleaning solution or method on a small, inconspicuous area of the stainless steel sheet before applying it to the entire surface. Additionally, refrain from using abrasive cleaners or scrubbing pads as they can cause scratches on the stainless steel.

- Q:Are stainless steel sheets suitable for water storage tanks?

- Yes, stainless steel sheets are suitable for water storage tanks. Stainless steel is known for its high resistance to corrosion, making it an excellent choice for storing water. It is durable, long-lasting, and does not require frequent maintenance. Stainless steel sheets also have a smooth and non-porous surface, which prevents the growth of bacteria and ensures the water remains clean and safe for consumption. Additionally, stainless steel is also resistant to UV rays, extreme temperatures, and chemicals, making it a reliable material for water storage tanks.

- Q:What are the applications of stainless steel sheets in the automotive industry?

- Stainless steel sheets are widely used in the automotive industry due to their numerous beneficial properties. These sheets find applications in various components and parts of automobiles, contributing to the overall performance, durability, and aesthetics of vehicles. One of the key applications of stainless steel sheets in the automotive industry is in the production of exhaust systems. Stainless steel is highly resistant to corrosion and heat, making it an ideal material for exhaust pipes. These sheets can withstand the high temperatures generated by the engine, ensuring longevity and reliability of the exhaust system. Additionally, stainless steel sheets are used in the manufacturing of automotive body panels. They provide excellent strength and rigidity, allowing for the production of lightweight yet sturdy body parts. Stainless steel's resistance to corrosion is also advantageous, as it ensures that the body panels do not degrade over time, even in harsh weather conditions. Furthermore, stainless steel sheets are employed in the production of fuel tanks and other fluid storage components. Stainless steel's corrosion resistance and ability to withstand high pressure make it a suitable material for these applications. The use of stainless steel in fuel tanks ensures that they remain leak-free and durable, leading to enhanced safety and longevity. Moreover, stainless steel sheets are utilized in the production of various interior and exterior trim parts. These include decorative elements such as grilles, trims, and accents, which enhance the aesthetics of the vehicle. Stainless steel's ability to be polished and finished to a high shine adds a touch of elegance and sophistication to the car's design. In summary, stainless steel sheets have numerous applications in the automotive industry. They are used in exhaust systems, body panels, fuel tanks, and trim parts, among others. The exceptional properties of stainless steel, such as corrosion resistance, heat resistance, and strength, contribute to the overall performance, durability, and aesthetics of automobiles.

- Q:Can stainless steel sheets be used for beer tanks?

- Indeed, beer tanks can utilize stainless steel sheets. The durability, corrosion resistance, and hygienic characteristics of stainless steel make it a prevalent material choice for beer tanks. To safeguard the quality of the beer and prevent contamination, stainless steel sheets are frequently employed in crafting the walls and inner surfaces of beer tanks. These sheets can be skillfully fabricated and welded together to form a seamless tank that can endure the pressure and temperature demands of the brewing procedure. Furthermore, stainless steel is effortlessly cleaned and maintained, rendering it an impeccable material for beer tanks.

- Q:Are stainless steel sheets suitable for water treatment plants?

- Water treatment plants find stainless steel sheets highly suitable due to their excellent corrosion resistance. In such facilities, materials are constantly exposed to water and various chemicals, making this resistance crucial. Stainless steel sheets resist rust and corrosion caused by water, chlorine, chloramines, and other commonly used disinfectants in water treatment processes. Moreover, stainless steel can withstand high temperatures, making it ideal for use in water treatment plants that apply heat during specific treatment processes. Additionally, stainless steel is hygienic and easy to clean, ensuring the water remains free from contaminants or impurities. Overall, stainless steel sheets are a reliable and long-lasting choice for water treatment plants because of their corrosion resistance, durability, and hygienic properties.

- Q:How do you clean stainless steel sheets?

- To clean stainless steel sheets, you can follow a simple and effective process. First, remove any loose dirt or debris from the surface by gently wiping it with a soft cloth or sponge. Next, prepare a cleaning solution by mixing warm water with a mild detergent or dish soap. Dip a non-abrasive sponge or cloth into the solution and gently scrub the stainless steel sheet in the direction of the grain. Avoid using abrasive materials or harsh chemicals as they can damage the surface. Rinse the sheet thoroughly with clean water to remove any soap residue. Finally, dry the sheet with a soft cloth or towel, again following the grain to prevent water spots or streaks. This process will help maintain the shine and cleanliness of your stainless steel sheets.

- Q:How do you prevent galling when using stainless steel sheets?

- To prevent galling when using stainless steel sheets, there are several measures you can take: 1. Lubrication: Apply an appropriate lubricant or anti-seize compound on the contact surfaces to reduce friction. This helps to create a barrier between the stainless steel sheets and prevent them from sticking and galling. 2. Proper surface finish: Ensure that the stainless steel sheets have a smooth surface finish. Rough or uneven surfaces can increase the risk of galling. Consider using sheets with a polished or finely ground finish to minimize the chance of galling. 3. Control the contact pressure: Avoid excessive pressure when using stainless steel sheets. Excessive pressure can generate heat and increase friction, leading to galling. Adjust the pressure to a level that allows smooth movement without causing excessive friction. 4. Minimize sliding or rubbing: Reduce the amount of sliding or rubbing between stainless steel sheets. If possible, use rolling or lifting techniques instead of dragging or sliding the sheets across each other. This helps to minimize the risk of galling by reducing the contact area and friction. 5. Use compatible materials: When using stainless steel sheets in contact with other materials, ensure they are compatible. Some materials, such as aluminum or certain coatings, can promote galling when in contact with stainless steel. Choose materials that are less prone to galling or use protective coatings to prevent direct contact. 6. Avoid excessive heat: Excessive heat can increase the likelihood of galling in stainless steel sheets. Ensure that the temperature is controlled and does not reach levels that can cause the sheets to heat up significantly. This can be achieved through proper cooling methods or by using heat-resistant materials if necessary. By following these preventive measures, you can significantly reduce the risk of galling when using stainless steel sheets, ensuring smooth operation and prolonging the lifespan of the sheets.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Rolled Stainless Coils,Cold Rolled Stainless Coils,NO.1 Finishe,NO.2B Finish Steel Coils

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 18 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords