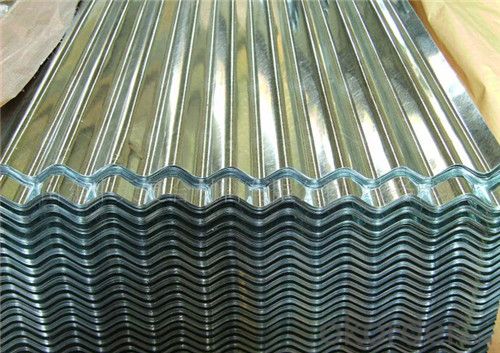

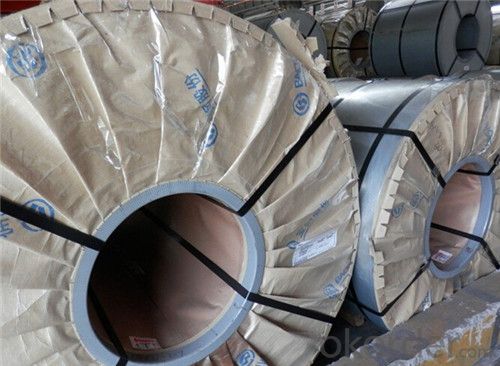

Cold rolled galvanized steel coil Q235 for construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 36 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

cold rolled steel coil

Cold-rolled full hard coils will become batch annealing coil after relatively long time and complete recrystallization annealing in batch furnace and finishing. Such products has excellent plasticity, formability and suitable strength, can be wildly used in the field of next step treatment of punching and pressing forming and stretching, to make products like oil barrels, furniture, building materials.

Continuous annealed strip

Cold rolled full hard coils will become continuous annealed coil after recrystallization annealing and finishing in the continuous annealing line. Such products has mutually well-matched strength and plasticity, can be widely used in field of the next step treatment of cold forming, biting and non-punching, pressing and stretching forming, to make industrial cabinets, office furniture, building components and so on.

Specification (mm) | Batch annealed strip and coils | (0.2-2.0)*(600-1250) |

Continuous annealed strip and coils | (0.2-2.0)*(600-1250) | |

Grade | Q195-Q235/Q195L, SPHC/SPHD/SPHE/DX51D/DX52D/DX53D. | |

Executive standards | DIN, JIS, GB, enterprise standard | |

Edge condition | EC/EM | |

Surface treatment | Oiled/dry | |

Delivery format | Coils | |

Package type | Simple, Normal, Best | |

- Q: What is the lifespan of steel coils?

- The lifespan of steel coils can vary depending on various factors such as the quality of the steel, the environment it is exposed to, and how well it is maintained. However, on average, steel coils can last anywhere from 10 to 30 years.

- Q: so what is stronger tempered steel Blade or carbon steel Blade? a Machete made of those i said above what will last longer,what can cut better,which will will shatter first.

- 1. all steel blades are tempered, whether they are high carbon blades or low carbon blades. 2. It depends on what kind of steel they are made from. So im going to answer this question, using the following qualifications. 440A stainless steel 440C stainless steel - high carbon. The higher the carbon level, the more brittle a blade becomes. But the higher the carbon level, will increase a steel’s wear resistance , meaning it will have a better edge retention 2. They both will work well. Pros's / Con's The 440C blades will need less sharpening, but are harder to sharpen The 4401 blades will need to be sharpened more, but are far easier to resharpen. So it basically comes down to where you will be using them and how you will be using them. If your gonna be out in the middle of the jungle and stopping for the night, then the high carbon blade would probably be better, you use it all day, resharpen it at night. If your gonna be cutting brush, tobbaco, etc on your land, then the 440A would be better, because you can take a couple of min's to resharpen it often

- Q: I bought this Brinks pad lock and it says boron steel on the lock. I was just wondering what exactly is boron steel and how hard/tough is it?

- Boron steel is rather hard, it is by no means titanium, but certainly better than mild steel. However, as with all metals, hardness is inversely proportional to flexibility, meaning that a good solid whack with a sledge hammer could crack your lock.

- Q: I need to identify a metal. It is rusty so I suspect it is either iron or steel. Since they both have similar densities and are magnetic, how do I tell the difference betweeen steel and iron?

- Steel is a refined, alloyed metal that is mostly iron. Iron, in a chemistry sense os simply Fe. In an industrial sense iron is pig iron commonly saturated with carbon, up to 4.5% and has other impurities like sulfur. Pig iron is brittle and should break rather easily, and bend very little. After a piece is broken look at the crystal structure, you should see rather small crystals. Most steel made for car body's, washing machines, file cabinets, low grade bolts and nuts etc. should flex and bend before breaking. Most steel made for things like cutting tools, axles, etc, is hardened and will chip and break rather than bend. Also you can try to heat the piece to a glowing orange temperature. It must be very hot. Cool it. If there is a lot of white flake scale on the piece it is impure and probably iron of some sort. In the end the only way exactly tell is have an analysis done and look at the chemistry.

- Q: Will a stainless steel mesh screen scratch a titanium cup, or vice versa?I have a titanium french press and am thinking about replacing the included press with an all steel one. I am worried about little flakes of titanium or steel getting ground off into the coffee when the press slides in and out. The original press has a polyester cloth for a screen, so nothing scratches.

- Will Titanium Scratch

- Q: How do steel coils contribute to the HVACR equipment industry?

- Efficient heat transfer and effective functioning of HVACR systems are crucial roles played by steel coils in the HVACR equipment industry. These coils, made of high-quality steel, are integral components of air conditioners, heat pumps, refrigerators, and boilers. Facilitating heat transfer is one of the primary functions of steel coils in HVACR equipment. Designed to efficiently transfer heat between the refrigerant and the surrounding air or water, these coils utilize a large surface area and good thermal conductivity. As a result, HVACR equipment can effectively cool or heat a given space, ensuring optimal energy efficiency and reducing operating costs in residential and commercial applications. In addition to heat transfer, steel coils contribute to the overall durability and longevity of HVACR equipment. The use of corrosion-resistant steel in these coils helps prevent damage from moisture and other environmental factors. This reliability is particularly important as HVACR systems often face harsh conditions and must operate continuously to maintain comfortable indoor environments. Furthermore, steel coils offer versatility and customization options to meet specific HVACR requirements. Manufacturers can vary the size, shape, and configuration of the coils to fit available space and optimize performance. This flexibility enables efficient integration of steel coils into different HVACR equipment, ensuring they meet the specific heating and cooling needs of diverse environments. In conclusion, steel coils are indispensable in the HVACR equipment industry. They enable efficient heat transfer, enhance durability, and offer customization options, ensuring effective functioning and energy efficiency of HVACR systems. Manufacturers can provide reliable and long-lasting solutions for heating, ventilation, air conditioning, and refrigeration needs in residential and commercial settings by incorporating high-quality steel coils into their products.

- Q: What are the different types of steel alloys used in coils?

- There are several different types of steel alloys commonly used in coils, each with its own unique properties and characteristics. Some of the most common types include: 1. Carbon Steel: This is the most basic and widely used type of steel alloy in coils. It contains a low amount of carbon and is known for its strength and durability. Carbon steel coils are often used in applications where high strength is required, such as automotive parts, construction materials, and machinery components. 2. Stainless Steel: Stainless steel coils are made from an alloy of iron, chromium, and other elements. They are highly corrosion-resistant and have excellent strength and heat resistance properties. Stainless steel coils are commonly used in applications where resistance to corrosion and staining is important, such as kitchen appliances, medical equipment, and transportation components. 3. Galvanized Steel: Galvanized steel coils are made by coating regular carbon steel with a layer of zinc. This coating provides excellent corrosion resistance and protects the underlying steel from rusting. Galvanized steel coils are commonly used in outdoor applications, such as roofing, fencing, and automotive body parts. 4. Alloy Steel: Alloy steel coils are made by adding various alloying elements, such as manganese, nickel, chromium, or molybdenum, to carbon steel. This enhances the strength, hardness, and wear resistance of the steel. Alloy steel coils are often used in applications where high strength and toughness are required, such as in the manufacturing of machinery, tools, and construction equipment. 5. Electrical Steel: Electrical steel coils are specifically designed for use in electrical equipment, such as transformers and electric motors. They have low electrical resistance and high magnetic permeability, allowing them to efficiently conduct electricity and create magnetic fields. Electrical steel coils are typically made from a silicon alloy, which improves their electrical and magnetic properties. Overall, the choice of steel alloy for coils depends on the specific requirements of the application, such as strength, corrosion resistance, electrical conductivity, or heat resistance.

- Q: Not sure if stainless steel is actually sealable but what's the best way to clean a brushed stainless steel appliance to not get so many finger prints...etc. I have stainless steel wipes that I used on another appliance and they don't work so great.

- Make a paste from Lemon Juice and salt, scrub gently, and then rinse with water. To clean a stainless steel surface, use mild detergent,or baking soda or vinegar diluted in water. Clean, then dry with a soft cloth. Most stainless steel has a grain; if you are using any kind of an abrasive on a stainless surface, always make sure you clean in the direction of the grain. The don'ts are: Don't use bleach. Don't use steel wool unless it is an absolute last resort. Some of the fine particles can lodge in the surface of the stainless and will eventually rust, giving the appearance that the stainless itself is rusting. Don't let the following food items (ketchup, mustard, mayonnaise, lemon juice, vinegar, salt, salad dressings) remain on your stainless surfaces for any length of time. If they sit on the stainless for more than a few minutes, they may bleach it out. You can actually rub out this white area with a very fine Scotchbrite pad. Make sure you are going along the grain lines and not at right angles to them.

- Q: I am searching for an online article which discusses any aspect of the use of austenitic stainless steels. I was just wondering if anyone could help me find one. No sales articles. Thank you!

- *Austenitic, okorder

- Q: How are steel coils processed for edge trimming or shearing?

- Steel coils are processed for edge trimming or shearing by first uncoiling the coil and feeding it into a machine equipped with either rotary shears or slitting knives. These tools trim or shear the edges of the coil to remove any irregularities, ensuring a precise and uniform width. The trimmed edges are then inspected for quality and smoothness before the coil is recoiled for further processing or storage.

Send your message to us

Cold rolled galvanized steel coil Q235 for construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 36 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords