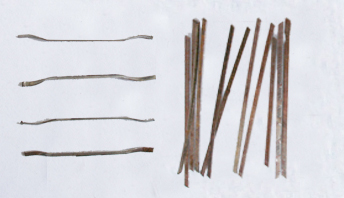

Cold Lace-off stainless steel fibers

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Cold Lace-off stainless steel fibers

Cut from high quality stainless steel wire is mainly used for refractory castable, it has superior tensile strength and flexibility.

Product function:

A, enhanced fire resistance of refractories

B, extend the life of refractories and endurance

C, reduce downtime and maintenance costs

Product specifications and models:

Chemical Composition melting range Diameter (mm) Tensile strength (MPa)

Cr Ni maximum average

304 18-20 8-10 2550-2650 1800 0.4-1.0 ± 0.02 ≥1200

31024-2619-22 2550-26502100

Application:

Used in refractory enhancement industry, such as oil, steel, chemicals, cement.

- Q: What are the different types of steel profiles used in architectural designs?

- There are various types of steel profiles commonly used in architectural designs, such as I-beams, H-beams, channels, angles, and tubes. These profiles offer different structural properties and can be used to create a wide range of architectural elements, including columns, beams, trusses, and frames. The choice of steel profile depends on the specific design requirements, load-bearing capacity, and aesthetic preferences of the project.

- Q: How is steel used in the agricultural industry?

- Steel is commonly used in the agricultural industry for various purposes such as constructing buildings, barns, and storage facilities, manufacturing agricultural equipment like tractors, plows, and harvesters, as well as fencing and irrigation systems. Its strength, durability, and resistance to corrosion make it an ideal material for these applications, ensuring the longevity and efficiency of agricultural operations.

- Q: How are steel products used in the construction of residential buildings and housing complexes?

- Steel products are extensively used in the construction of residential buildings and housing complexes due to their strength, durability, and versatility. They are commonly employed in the structural framework, such as beams, columns, and trusses, providing a sturdy and stable support system. Steel is also used for reinforcing concrete, increasing the strength and resistance of the building against various forces. Additionally, steel is utilized in the construction of roofing systems, wall panels, stairs, and balconies, offering aesthetic appeal and long-lasting performance. Overall, steel products play a crucial role in ensuring the safety, stability, and longevity of residential buildings and housing complexes.

- Q: What are the different types of steel scaffolding systems?

- There are several types of steel scaffolding systems, including tube and coupler scaffolding, system scaffolding, and frame scaffolding. Tube and coupler scaffolding consists of tubes and couplers that are connected together to form a stable structure. System scaffolding uses pre-designed components that can be easily assembled and dismantled, providing flexibility and efficiency. Frame scaffolding is made up of frames and cross braces, offering a simple and sturdy solution for construction projects.

- Q: What are the advantages of using steel in the manufacturing of solar panels?

- There are several advantages of using steel in the manufacturing of solar panels. Firstly, steel is a strong and durable material, which ensures the longevity and reliability of the solar panels. Secondly, steel is readily available and cost-effective, making it an economical choice for mass production. Additionally, steel is highly recyclable, reducing the environmental impact of solar panel production. Lastly, steel's high thermal conductivity allows for efficient heat dissipation, preventing damage to the solar cells and ensuring optimal performance.

- Q: How do steel products contribute to the food and beverage industry?

- Steel products contribute to the food and beverage industry by providing essential equipment and infrastructure. Steel is used to manufacture food processing machinery, such as mixers, extruders, and cutting equipment, which helps streamline production processes and improve efficiency. Steel storage tanks and containers ensure the safety and hygiene of food and beverages during transportation and storage. Additionally, steel is used to construct commercial kitchens, refrigeration units, and packaging materials, ensuring that the food and beverage industry operates smoothly and maintains high standards of quality and safety.

- Q: How is steel used in the production of process equipment for chemical plants?

- Steel is commonly used in the production of process equipment for chemical plants due to its exceptional strength, durability, and resistance to corrosion. It is used to construct various components such as storage tanks, pressure vessels, pipes, and heat exchangers, ensuring the safe handling and processing of chemicals. Additionally, steel can withstand high temperatures and pressure, making it suitable for the harsh operating conditions found in chemical plants.

- Q: How do steel products contribute to the agriculture and farming sector?

- Steel products contribute to the agriculture and farming sector in various ways. For instance, steel is widely used in the construction of farm buildings, such as barns and storage facilities, providing durable and long-lasting structures to house livestock, equipment, and crops. Additionally, steel is utilized in manufacturing machinery and equipment used in farming operations, including tractors, plows, harvesters, and irrigation systems, making these tools more robust and efficient. Furthermore, steel is instrumental in the production of fencing materials, aiding in the establishment of secure boundaries and enclosures for livestock. Overall, steel products enhance the productivity, safety, and sustainability of the agricultural industry.

- Q: How is steel wire rope inspected for safety?

- Steel wire rope is inspected for safety through a comprehensive process that includes visual examination, non-destructive testing techniques, and load testing. Trained inspectors carefully examine the rope for any visible signs of wear, corrosion, or damage. Non-destructive testing methods such as magnetic particle inspection or ultrasonic testing are used to detect any internal flaws or defects that may not be visible. Additionally, load testing is conducted to determine the rope's ability to withstand its specified working load. Through these rigorous inspections, the safety of steel wire rope is ensured, reducing the risk of failure and promoting safe operations.

- Q: What are the key characteristics of stainless steel?

- The key characteristics of stainless steel are its high corrosion resistance, durability, strength, and ability to maintain its appearance over time. It is also known for its low maintenance needs, heat resistance, and wide range of applications in various industries.

Send your message to us

Cold Lace-off stainless steel fibers

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords