Coated aluzinc steel coil For Metal Roofing

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 17654 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

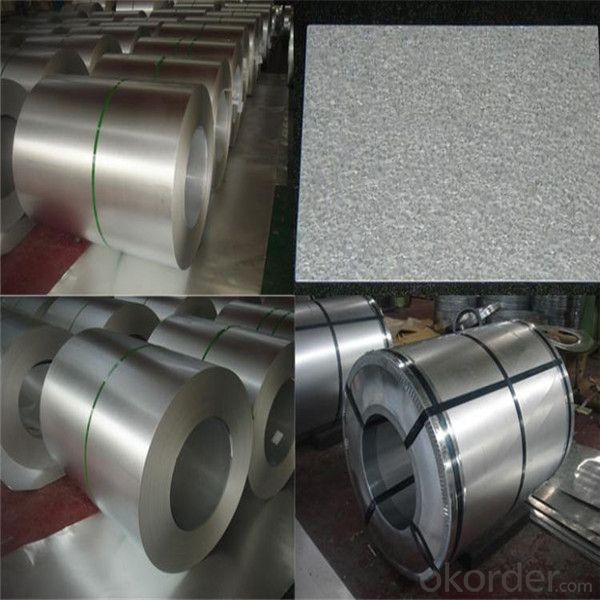

Hot –dip aluzinc steel sheet/coil is substrated on cold rolled steel (CRC) in various strength and specification. Coating

composition is 55% aluminum in weight ratio, 43.4% zinc, and 1.5% silicon, with excellent corrosion and heat resistance

performance.

Galvalume steel sheet combines the excellent barrier corrosion protection of aluminum with the galvanic

protection of zinc. The result is a coating that lasts a long time, a coating that provides cut-edge protection

along sheared edges, and therefore, a coating that offers excellent protection to steel sheet. Although there

are a few exceptions, for most applications in most types of environment, Galvalume steel sheet is the preferred

product when long-term resistance to atmospheric corrosion is desired.

Standard and Grade :

Hot-dip Aluzinc steel coils | ||||

ASTM A792M-06a | EN10327-2004 | JIS G 3321:2010 | AS- 1397-2001 | |

Commercial quality | CS | DX51D+AZ | SGLCC | G1+AZ |

Structure steel | SS GRADE 230 | S220GD+AZ | SGLC400 | G250+AZ |

SS GRADE 255 | S250GD+AZ | SGLC440 | G300+AZ | |

SS GRADE 275 | S280GD+AZ | SGLC490 | G450+AZ | |

SS GRADE 340 | S320GD+AZ | SGLC570 | G450+AZ | |

SS GRADE 550 | S350GD+AZ | G500+AZ | ||

S550GD+AZ | G550+AZ | |||

Application :

Production of cold formed corrugated sheet and profiles for roofing, cladding, decking, tiles, sandwich

walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

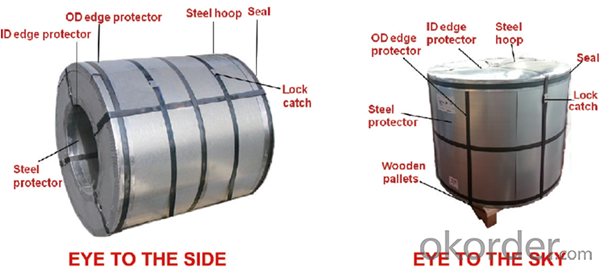

Packaging & Shipping

Packaging Detail | The packing of coil consists of anti-damp paper ,PVC film ,hardboard paper , steel box , strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye of the side) or wooden pallets(eye of the sky) |

Delivery Time | within 30 days of receipt of LC original or prepayment |

Our Services

MOQ | FCL, 25 metric tons per 20GP, can be assorted with different sizes. |

LCL for trial order is acceptable. | |

Price Term | EX-WORK, FOB China Port, CNF, CIF |

Payment | T/T, 30% advanced payment before production and balance before shipment; OR Irrevocable L/C at sight. |

Delivery Time | within 30 days of receipt of LC original or prepayment |

Our Advantage

* Professional Personnel of Steel Trading

* Strong Steel Industry Background

* Conveniently Geographic Location

FAQ

Q: How do you guarantee the quality of your product?

A: Every process will be checked by responsible QC which insures every product's quality.

Q: How much is your delivery time?

A: Normally within 30 days of receipt of LC original or prepayment, but mostly according to the

specific requirements or the quantity

Q: I need sample, could you support?

A: We can supply you with the sample for free, but the delivery charges will be covered by our customers.

For avoiding the misunderstanding, it is appreciated if you can provide the International Express Account for

Freight Collect. Also you can have a visit to us, welcome to CNBM!

- Q: Measures to prevent cold rolling of packaged cold rolled steel coils? Who can give some professional opinions oh?

- In order to prevent rusting in the process of storage or transportation of steel roll, steel mills generally take the following packing: inner gas antirust paper wrapped with tape wrapped in plastic film sealing, intermediate, involute cardboard seal lining, cardboard corner, with iron and steel outer package corner protector, strapping fixed. If the inner package seal, so the steel coil is sank into the water, will not rust out.

- Q: What are the common applications of cold-rolled steel coils?

- Cold-rolled steel coils have a wide range of common applications in various industries due to their exceptional qualities. One of the most common applications is in the automotive industry, where cold-rolled steel coils are used to manufacture car parts such as body panels, chassis components, and structural reinforcements. The high strength and excellent formability of cold-rolled steel make it ideal for these applications. Another common application is in the construction industry, where cold-rolled steel coils are used to fabricate structural elements for buildings and infrastructure. Cold-rolled steel is often used to make beams, columns, and other load-bearing components due to its superior strength and durability. Cold-rolled steel coils are also widely used in the manufacturing of appliances and consumer goods. They are commonly used to create the outer shells of refrigerators, washing machines, and ovens. The smooth and consistent surface finish of cold-rolled steel makes it perfect for these applications, as it provides an aesthetically pleasing appearance. Additionally, cold-rolled steel coils find applications in the electrical industry. They are used to produce electrical enclosures, transformers, and various other components due to their excellent electrical conductivity and magnetic properties. Overall, the common applications of cold-rolled steel coils span multiple industries, including automotive, construction, appliances, and electrical. The versatility, strength, formability, and aesthetic appeal of cold-rolled steel make it a preferred choice for many manufacturers in various sectors.

- Q: What are the advantages of using hot-rolled steel coils?

- Hot-rolled steel coils offer several advantages. Firstly, they have a higher strength-to-weight ratio, making them suitable for applications that require strong and durable materials. Secondly, hot-rolled steel coils have better formability, allowing for easier shaping and manipulation during fabrication. Additionally, these coils have a smoother surface finish, making them more aesthetically appealing and suitable for applications that require a polished appearance. Lastly, hot-rolled steel coils are generally more cost-effective compared to other steel manufacturing processes, making them a preferred choice for various industries.

- Q: How are steel coils cut into smaller sizes?

- To achieve smaller sizes for steel coils, there are diverse methods available, which depend on the desired dimensions and quantities. One widely used technique is slitting, where the coil is passed through a set of circular blades that simultaneously make multiple cuts, resulting in narrower steel strips. Slitting is commonly employed to produce narrow coils or strips tailored for specific applications like automotive parts or electrical components. Another option is shearing, which entails cutting the coil into smaller lengths using a straight blade. This method is typically chosen when precise dimensions are necessary, such as in the manufacturing of flat sheets or plates. Shearing can be carried out manually or with automated machinery. Furthermore, laser or plasma cutting techniques can be employed for certain types of steel coils. These methods offer greater flexibility in terms of shape and size, enabling intricate cuts or contours to be created. Laser or plasma cutting is frequently utilized in construction or fabrication projects when specific shapes or profiles are required. In summary, cutting steel coils into smaller sizes involves a range of techniques, including slitting, shearing, laser cutting, or plasma cutting. The selection of the method depends on factors such as the desired dimensions, quantities, and specific requirements of the end product.

- Q: ex: boat hull made out of steel

- Metal coating mean the best one is Titanium but it is more expensive .Go for epoxy putty with epoxy painting can solve your need

- Q: Galvanized Steel or Standard Steel. This will be for the grilling surface.

- Bare steel. Galvanized or ANY coated racks will produce deadly chemicals in the food when heated. Galvanizing is a tin coating applied to the surface of the iron. Cadmium is a deadly chemical when ingested and is one of the chemicals on refrigerator racks. I'm not sure about Stainless Steel. The safest way is if in doubt DON'T.

- Q: Is boron steel or carbon steel a harder metal? Which one is more flexible?

- There is really no simple answer to this question. Boron is usually used for a handful of reasons, but most center on high volume low cost production of durable hardened steel. Boron is a very cheap way to get very durable parts with very minimal alloying of expensive materials. It was born of necessity during WW2 and is currently in WIDE use in bulldozer undercarriage. Probably in place of what would otherwise be 4140. Boron steel is quite a bit more difficult to properly heat treat. Better suited to mass production facilities with tight controls, but when done properly provides material just as durable as higher alloys. Not a backyard endeavor such as ht/tempering carbon steel or tool steels without appropriate homework and treatment controls.

- Q: not iron, steel

- steel was first used in the 1800s in buildings.

- Q: What are the environmental impacts of steel coil production?

- The environmental impacts of steel coil production include emissions of greenhouse gases, such as carbon dioxide, during the process of extracting and processing raw materials like iron ore and coal. Additionally, the production of steel coils requires a significant amount of energy, contributing to the depletion of natural resources and increased carbon emissions. The wastewater generated during steel production can also contain pollutants, which may harm aquatic ecosystems if not properly treated. Furthermore, the disposal of steel coil waste, such as slag and other by-products, can pose challenges in terms of proper handling and potential contamination of soil and water sources. Overall, steel coil production has substantial environmental impacts that demand sustainable practices and mitigation measures.

- Q: How are steel coils used in the production of steel screws?

- Steel coils are used in the production of steel screws by being unwound and fed into a machine that cuts and shapes them into individual screw blanks. These blanks are then threaded and undergo various processes to create the final steel screws.

Send your message to us

Coated aluzinc steel coil For Metal Roofing

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 17654 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords