Aluzinc Steel Sheet in Coil with Prime Quality and Lowest Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluzinc Steel Coil Description:

Hotdip aluzinc steel sheet is substrated on cold rolled steel(CRC) in various strength and specification. Coating composition is 55% aluminium in weight ratio, 43.4% zinc, and 1.5% silicon, with excellent corrosion and heat resistance performance. It is especially useful for countless outdoor and industrial applications.

2.Main advantages of the Galvanized Steel Coil:

• Base material for countless outdoor and industrial applications

• Excellent corrosion resistance

• Excellent heat resistance performance

• High strength

• Good formability

• Rust- proof ability

• Good visual effect

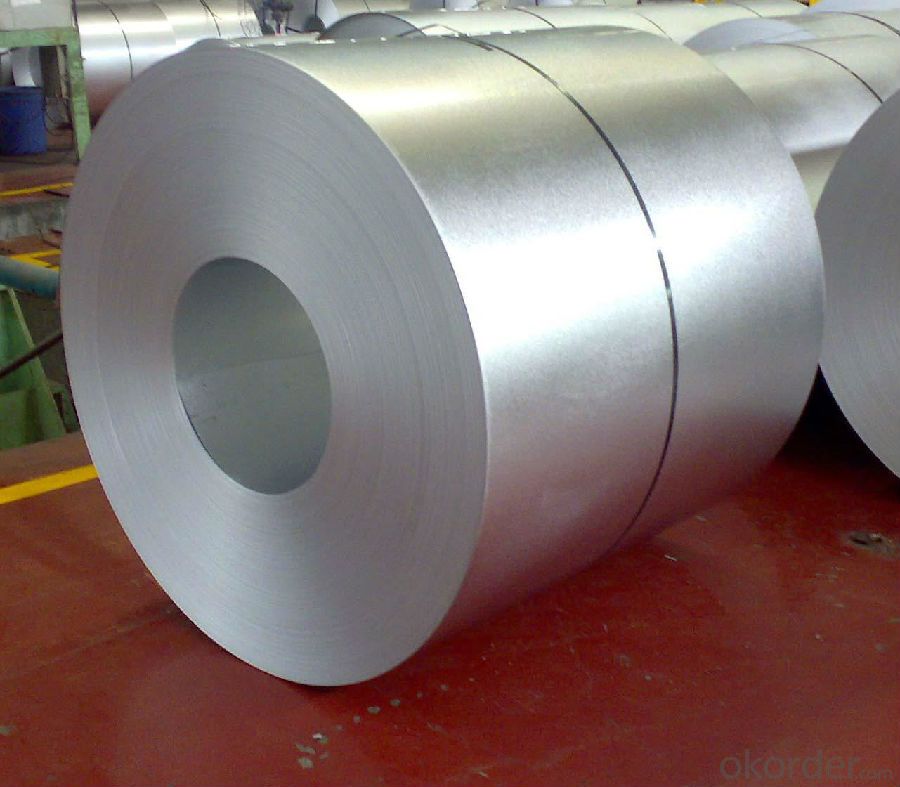

3. Aluzinc Steel Coil Images:

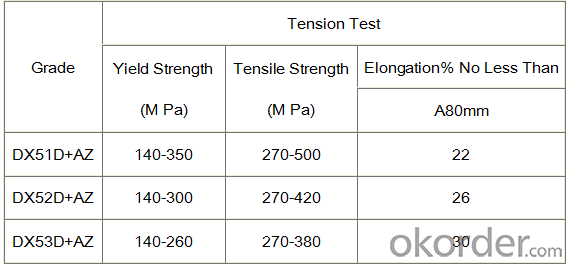

4.Aluzinc Steel Coil Specification

Thickness: 0.3-0.7mm

Width: 914-1250mm

Inner Diameter: 508-610mm

Weight of Steel Coil: 3-15MT

Coating Type: Al-Zn Alloy

Available Dipped Layer: 50-150g/m2

Surface Finish Structure: Normal Spangle & Small Spangle & Zero Spangle

Available Surface Treatment: Passivating & Oiling & AFP & Filming

5.FAQ of Aluzinc Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What are the different types of steel coil storage racks?

- There are several types of steel coil storage racks, including coil cradles, coil saddles, coil c-hooks, and coil racks with dividers.

- Q: How are steel coils inspected for oil or rust residues?

- Steel coils are typically inspected for oil or rust residues through visual examination, as well as using various testing methods such as wiping the surface with a white cloth to check for any visible stains or residues. Additionally, some inspectors may also use specialized equipment such as ultraviolet lights or moisture detectors to identify any hidden oil or rust contaminants.

- Q: Steel used to be made in the #92;Bessemer Converter, write about how steel making processes today produce better quality steel????

- how we can prepared steel by using converter? ans it

- Q: How are steel coils used in the manufacturing of food packaging?

- Steel coils are commonly used in the manufacturing of food packaging as they are shaped and formed into cans, containers, and lids, providing a strong and durable material for ensuring the safety and preservation of food products.

- Q: What are the common coil lengths available for steel coils?

- The common coil lengths available for steel coils vary depending on the industry and specific requirements. However, some standard coil lengths are commonly used across various applications. These include coil lengths of 100 feet (30.48 meters), 200 feet (60.96 meters), 300 feet (91.44 meters), and 500 feet (152.4 meters). These lengths are often used in industries such as construction, manufacturing, and automotive, where steel coils are widely used for various purposes. It is important to note that coil lengths can also be customized based on specific project needs or customer preferences.

- Q: engineering sloutions related to steel fabrication

- The American Institute of Steel Construction develops codes for steel building design in the U.S. See the link to below to the Steel Solutions Center at their website. You can find free programs for designing structural steel elements from clicking on technical resources at that link. Most of the programs presume that you are a structural/civil engineer with knowledge of the steel design specifications.

- Q: I was watching a documentary on the samurai vs the European knight. It said that the when Japan was being invaded by the (cant remember) they needed a new weapon. The enemies armor made iron swords useless. While steel swords broke when in combat. So to combat this the Japanese made a hybrid sword. They used a special mold that made the swords back iron while the part that makes contact with the enemy was steel. Also the sword was curved so it increased its armor and cutting power. This revolutionary design made the the sword stronger. The iron back made it not break while the steel edge made it cut through the enemies armor. I want to know how iron is stronger than steel, and how steel can cut better than iron.

- Yes because metal alloys are comparatively more strong than pure metal.The worst thing is that iron gets rusted whereas steel does not.And the skyscrapers are made of steel buddy , iron is not used in them.

- Q: haii, i have this guitar thats quite old and im not quite sure whether to put steel strings on it. there were very thin badly worn steel strings on it when i got it, so i think its an acoustic

- That's a very low-end Kay, maybe from the 60's or 70's. It has a weird mixture of steel-string and classical features that you often see in cheap imports from around that time, maybe because the factory didn't want to stock different parts for different lines. The tuners (one of which is missing) are made for steel strings. They will work with nylon but not well. The bridge is a generally classical type but appears to be bolted on and seems to have some compensation carved into the saddle, which indicates it may have been intended for steel strings. Probably it's ladder braced, which is not a great design for either type. It has a classical rosette and a steel-string pickguard. I am guessing the neck has steel reinforcement but unless there's a sticker there's no way to tell. Personally I'd put light or (preferably) extra-light steel strings on it. The short scale length will help keep the tension down. I'd keep an eye on the neck though. You could also try silk steel to be on the safe side, but the bass response will probably be lacking.

- Q: Can steel coils be used in the production of HVAC systems?

- Certainly, HVAC systems can make use of steel coils. In the production of HVAC equipment, like air handlers, condenser coils, evaporator coils, and heat exchangers, steel coils are frequently employed. Their durability and strength make them well-suited to endure the rigorous pressures and temperatures involved in HVAC operations. Moreover, steel coils possess favorable heat transfer properties, facilitating efficient heat exchange between the refrigerant and the conditioned air. In summary, steel coils are an dependable and widely-utilized element in the manufacturing of HVAC systems.

- Q: How are steel coils used in the manufacturing of doors and windows?

- Steel coils are used in the manufacturing of doors and windows by being processed into flat sheets or strips, which are then cut, shaped, and formed into various components such as frames, panels, and reinforcements. The steel coils provide strength, durability, and stability to the final products, ensuring high-quality doors and windows that can withstand different weather conditions and provide security to buildings.

Send your message to us

Aluzinc Steel Sheet in Coil with Prime Quality and Lowest Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords