Galvanized/Aluzinc Steel Roof High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

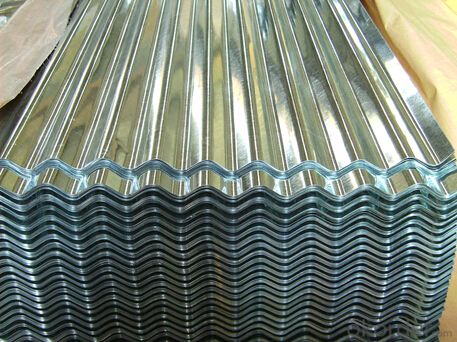

1. Hot-Dip Galvanized Steel Roof Description:

Hot-dip galvanized steel roof are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial application.

2.Main Features of the Hot-Dip Galvanized Steel Roof:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

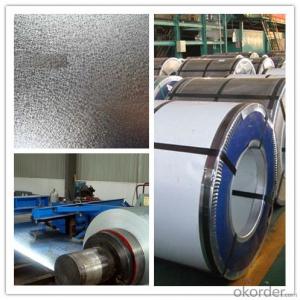

3.Hot-Dip Galvanized Steel Roof Images

4.Hot-Dip Galvanized Steel Roof Specification

Material: Galvanized Sheet

Width: 650/800/890/900

Length: 1500/1800/2000/2400/3005/3600 or customized

Thickness: 0.2-2.0

Surface Treatment: Hot dipped/Bended

Application: warehouse; shelter; Commercial facilities; industrial facilities

5.FAQ of Hot-Dip Galvanized Steel Roof

Which payment term we can do?

L/C at sight or T/T.

What’s the basic material of this product?

Galvanized/Aluzinc Steel

- Q: benchmade mpr with m390 steel knife. Is it better than d2 s30v or 154cm steel?

- well first of all u hav 2 get a mpR490 STEEL STOOLMADE

- Q: Are Danielle steel books good to read. Im 15 , but do I have to wait until Im a bit older.

- Wait until you are eighty, the dementia will make the process less painful Otherwise, you know best how mature you are and Danielle Steel is sugary romance, not really sex.

- Q: I am looking to weld some stainless steel using stainless electrodes. I was told that the arc welder needs to be able to run in DC in order to be able to weld stainless steel. Is this true? Or can you weld stainless steel with stainless electrodes with AC also?

- there are tradeoffs to the various methods you can use. Check out this link for the scoop on what they are and what the settings should be given the material you are using and the type of welder you decide to use.

- Q: rust is not a issue. i was looking a D2 steel but heard story's of it chipping and breaking

- A okorder /

- Q: What are the different types of steel coil treatments?

- Enhancing the properties and performance of steel coils involves various types of treatments. The treatments include: 1. Heat treatment known as annealing. It involves heating the steel coil to a specific temperature and gradually cooling it. This treatment alleviates internal stresses, enhances ductility, and boosts the overall strength of the coil. 2. Chemical treatment called pickling. It entails submerging the steel coil in an acid or chemical solution to eliminate impurities, scale, and rust from the surface. This treatment enhances the surface finish and cleanliness of the coil. 3. Application of a protective coating such as oil. A thin layer of oil or another protective substance is applied to the surface of the steel coil. This treatment prevents corrosion, improves lubricity, and safeguards the coil during storage and transportation. 4. Galvanizing, a process that involves coating the steel coil with a layer of zinc. This protective layer shields the coil from corrosion, creating a barrier between the steel and the surrounding environment. It ensures long-term durability and resistance to rust. 5. Tempering, a heat treatment process that includes heating the steel coil to a specific temperature and swiftly cooling it. This treatment enhances the toughness and strength of the coil, making it more resistant to impact and deformation. These are just a few instances of the various types of steel coil treatments commonly employed. Each treatment has its own unique purpose and advantages, and the choice of treatment will depend on the desired properties and applications of the coil.

- Q: I'm looking for the weight of different types of steel and haven't found anything helpful!!thank you

- Category Material Density Metal Steel, tool 7.715 Metal Wrought Iron 7.75 Metal Carbon Tool Steel 7.82 Metal Steel, cold-drawn 7.83 Metal Carbon Steel 7.84 Metal Steel, C1020, HR 7.85 Metal Pure Iron 7.86 Metal Soft Steel (0.06% C) 7.87 Metal Stainless Steel, 304 8.03 Metal Stainless 18Cr-8Ni 8.03 I looked up specific gravity mild steel. This might get you pointed in the right direction.

- Q: They are showing on tv a special on how the new World Trade Center, building 1, is being built. Focusing on the steel and the guys fitting everything together.Where do builders go to buy all that steel framing? We do not build really tall buildings where I live so most of the steel is cut and welded on the job site. At World Trade Center 1, they seem to get the steel on trucks; already cut and welded.

- The steel is all custom fabricated in what are called structural steel fabrication shops. Each Building is designed by architects then the frame is designed by engineers to support whatever load is being applied to the building. After the engineering is done it goes out for a bid package where a fab shop estimates how much to charge for the fabrication of the steel and the erection of the steel. Once a company wins the bid, it then has to design how the steel will connect with one another and have it approved by an engineering firm to assure the connections are strong enough. Once all of that happens the fab shop orders raw steel beams and angle iron and steel plate at stock lengths. Beams are then cut into the right length and holes drilled in the proper places. The beam is then marked with a number that tells the erectors where it goes. The steel is then shipped out in batches to the construction site where it is unloaded and shook out into an organized place to grab them with a crane. They are then put together like a toy model, there are instructions that say what beam goes where and what size bolt to use. The welding you see being done is on really critical moments that need extra strength. That is about how it goes in a nutshell. It is a bit more complicated than that but it gives you an idea.

- Q: Steel steps steel guard rail steel chair. You see where I'm going with this.

- The guard rails have to be steel or fans would tear them apart. The steps have to be steel..( although they are not 'solid steel'), in order to hold all that weight of people going up and down them for an entire show. The chairs are very forgiving. All in all, I can see where you are going with this, however it has been this way for decades now. Notice there are no steel tables or steel announcers desks?

- Q: Can steel coils be customized in terms of size and specifications?

- Yes, steel coils can be customized in terms of size and specifications. Steel coils are typically manufactured in standard sizes and specifications, but they can be customized to meet specific requirements based on the needs of the customer. Customization can involve adjusting the dimensions of the coils to different widths, lengths, and thicknesses, as well as modifying the specifications such as the type of steel, surface finish, and coating. This allows steel coils to be tailored to various applications and industries, ensuring they meet the specific requirements and performance criteria of the customers. Customized steel coils are commonly used in industries such as automotive, construction, manufacturing, and appliances, where specific sizes and specifications are crucial for efficient and effective operations.

- Q: So carbon is gas that brakes down to hydrogen and helium before going in...And steel can go a little farther towards sun before evaporating.. 200 degrees closer at leastso steel is full of a heavier gas bomb in my hypothesis and needs to be broken up outside stars(broken down)Is steel capable of going into sun with an element thats wrong wayLike iron has no air to boil outAnd steel goes just as far with carbon in it..Other words can u answer me with..Carbon is already IN the sun and is capable of braking down Carbon INSIDE the star/sunOnly way I see steel boiling is inside and it releases carbon gas at once..carbon bomb

- Carbon is an element, which is your first oversight. The rest of you statements are not clearly presented. Let alone make any sort of sense.

Send your message to us

Galvanized/Aluzinc Steel Roof High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords