cnc engraving machine for woods 300*400 cm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.Syntec control system

2.9.0kw ai cooling spindle

3.Janpan Servo motor

4.Taiwan Hinwin rail

5.Vacuum table

Professional muti-function cnc engraving machine 1325

Main technical parameter

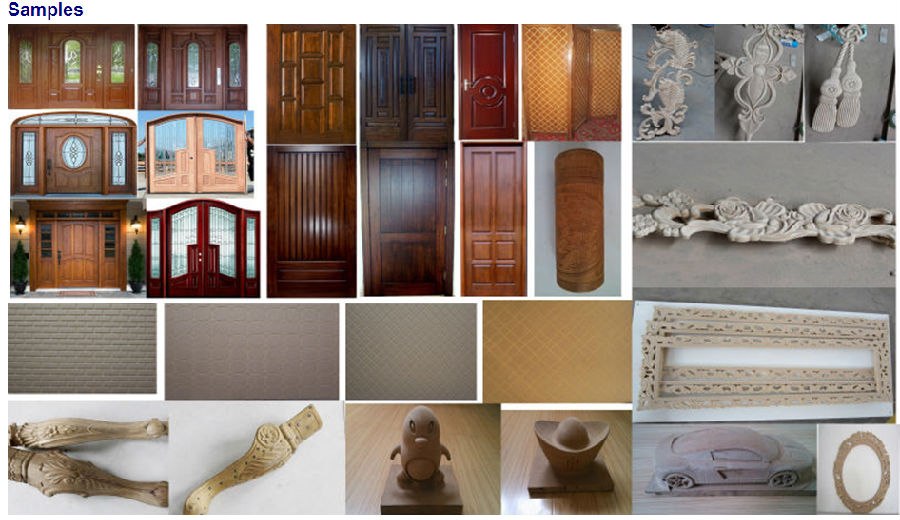

It can be used in carving on waved board, furniture door, arts door, paint free door, screen door and kinds of furniture.

Machine Size Work Envelope Repositioning Resolution Resolution Power Of Spindle Spindle Speed Max.Speed Max.Cutting Speed Bridge Clearance Control System Working Voltage Command Code | 2100×3500mm 1300×2500mm +0.02mm +0.001mm 9kw 0-18000(24000)rpm/Min 60000mm/Min 25000mm/Min 400mm SYNTEC control system AC380V/50Hz HPGL\G |

Machinery Characteristics:

Stable Structure: Square steel formed frame, stable and can not be deformed.

Perfect Parts: Imported Taiwan control system;AMT Line guide rail maid in Taiwan, due-row, four line ball slider, heavy loading and steady proceeding, German made ball lead screw with accurate cutting, Japan Servo Control system

Italy spindle motors.

l Good parts: The drive is more powerful: the use of well-known brands stepper motor,

become more powerful

l Armless automatic tool change system;magazine capacity 8(optional)

l High adhesion vacuum suction device;Displacement up to 230 cubic meters / hour

l Open software interface,.Excellent compatibility compatible of TYP3/ARTCAM/CASTMATE/WEITAI and other CAD/CAM design software Ensure that the design no problem.

- Q: What is the difference between a woodworking engraving machine and a computer operating system and a handle control system?

- Woodworking engraving machine handle control system advantage is to save space, and uses computer; drawback is relative to the operation of some trouble, after all, are all set in a control panel, the operation is not very easy to press the wrong button.Woodworking engraving machine computer control system has the advantages of processing can preview the effect, you can always see the processing path, if the program loading errors can be corrected timely; drawback is that requires a computer, increase the cost of production.

- Q: Woodworking engraving machine, how to engrave the double curved arc?

- A straight cut is enough, and the other side, in turn, must be fixed.

- Q: G -1325 large format high-speed engraving machine about how much money?

- Not heard, 1325. in the 30 thousand general ordinary advertising machine, woodworking machine at about 50 thousand and change the knife machine, choose the machine according to your product requirements to choose machine. And your company has near the point of service is very important. Maybe 30 thousand can meet, perhaps must choose 150 thousand

- Q: Woodworking computer engraving machine, how to do the Dragon scales?

- The dragon carved software in the first Linyao in painting, coloring, stacking, sit path output, have a few processes

- Q: How to realize arc plane with 1325 woodworking engraving machine

- If you want to cut this figure, the tool path menu has an outline cut, you can adjust the parameters inside, and then generate the path. Finally, output to the engraving machine inside.

- Q: Woodworking engraving machine carved PVC word lines have no vertical edges, what is the reason

- So does my machine. Please tell me how to solve it

- Q: What's the trouble when using a woodworking engraving machine? How to overhaul

- Woodworking engraving machine spindle motor burns:Solution: first check the pump is working, but also to see whether the lower level of circulating water.

- Q: Engraving machine model is determined by what, such as the new CX1325 woodworking machine, screw machine, CX1325 advertising engraving machine, two are CX1325, the same?

- Usually in accordance with the size of the table size, carpentry or advertising, it depends on the configuration.

- Q: Woodworking engraving machine; blanking; merits and demerits

- shortcomingPurchasing cost: compared to more than 10000, up to more than 20000 of the table saw, CNC cutting machine price is higher.The tool cost: because the cutter material, cutter loss to a large number of cheap tools to open the pictures in your tool to open about 100 pieces of plate

- Q: Want to do woodworking engraving machine this line, want to know the specific circumstances, it is best to engage in a friend to answer

- Woodworking engraving machine is divided into many kinds, such as large hollow carved carved doors and windows cut, embossed typeThere are small woodworking crafts, engraving machines. It depends on where you want to go.

Send your message to us

cnc engraving machine for woods 300*400 cm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords