2014 NEWES HEFEI SUDA newest engraving machine on promotion

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

| Condition: | New | CNC or Not: | CNC | Place of Origin: | Guangdong China (Mainland) |

| Brand Name: | LuckBerry | Model Number: | R-1618*6 | Voltage: | AC380V/50Hz |

| Power(W): | 1.5kw/2.2kw | Dimension(L*W*H): | 1500*1300*180mm | Weight: | 1500kg |

| Certification: | CE/ISO | Warranty: | 12months | After-sales Service Provided: | Engineers available to service machinery overseas |

| Net weight: | 1000kg | Spindle power: | 1.5KW | Spindle speed: | 6000-24000rpm/min |

| Working area: | 1600*1800*180mm | Diameter of cutter: | 3.175-16mm | Overall size: | 1600*1800*1500mm |

| Spindle quantity: | 6pcs | Spindle mode: | Water-cooling spindle | Max working speed: | 8m/min |

Packaging & Delivery

| Packaging Detail: | Standard Package: Thickness PE Foam inside ,poly film outside, wooden pallet is optional. |

| Delivery Detail: | 30 days after receiving down payment |

Specifications

R-1618*6 CNC Engraving Machine

1.Max working speed:8m/min

2.Spindle power:1.5KW water-cooling

3.Spindle speed:6000-24000rpm

R-1618*6-SG CNC Engraving Machine

Product Description

♦ Reference Picture of R-1618*6 CNC Engraving Machine :

♦ Specification of R-1618*6 CNC Engraving Machine :

Configuration of R-1618*6 CNC Engraving Machine:

| NO. | Detail Pictures | Items | Brand |

| 1 |  | Machine Structure | Cast steel body with aging & tempering treatment, solid and durable |

| 2 |

| T-Slot Worktable | T-Slot worktable clamp the workpiece directly, suit for small piece, cutting and hollow out processing. |

| 3 |

| Water-cooling Spindle | 6pcs * 1.5kw Hanqi Water-cooling Spindle

Strong Carving power, high precision, longer service life; Adopt grinding technology, can improve the motor concentricity, prolong service life.

|

| 4 |

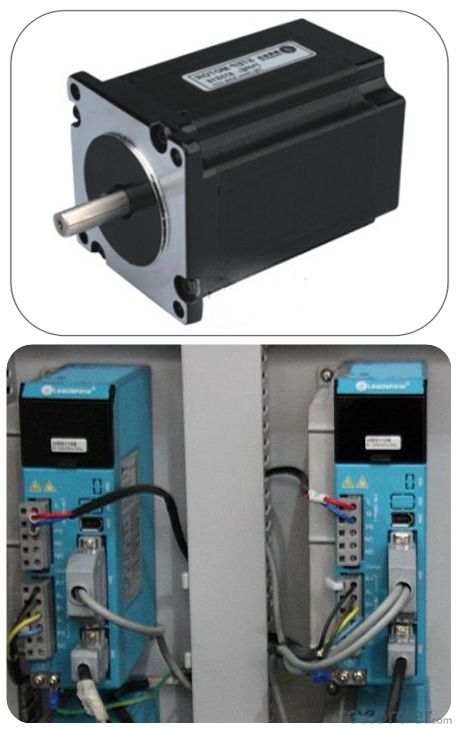

| Driving System | Leadshine Motor set with imported precision bearing, large torque, long working hours.

X,Y,Z axis drived by Leadshine driver, high resolution and positioning accuracy. |

| 5 |

| Transimission |

X,Y,Z axis adopt Taiwan AHK high precision preload anti-backlash ball screw, screw nut with tracking airtight dust removal device, guarantee the machine precision and service life.

|

| 6 |  | Guide Rail | Y axis adopt Taiwan Hiwin 20mm guide rail; X axis and Z axis adopts Taiwan Hiwin 20mm guide rail, adding scraping devices external and dust proof protection, extending the service life of the guide rail effectively. |

| 7 |

|

Electrical Component Breaker

|

Germany Schneider

|

| 8 | Frequency Inverter |

Sunfar Frequency Inverter

| |

| 9 | Electrical Compnent Cable | Special shielded cable drag chain special high flexible, can bend millions of times, drag chain support 150 degrees bend, effectively protect the cable. | |

| 11 | Approaching Sensor Switch | Dust proof, waterproof & antiseptic (3 pcs for X,Y and Z axis) | |

| 13 | Control System | Weihong System, visualization operation, real- time simulation, pretreatment ability | |

| 14 | Software Available | Artcam, Alphacam, Type 3, etc. CAD/CAM software compatible, identify G code, *.NC. | |

| 15 | Collect | 6 peice |

Workshop:

- Q: What is the price of multi head woodworking engraving machine?

- And hanging plate engraving machine, even if the number of engraving more, but also a set of drives and drive motor to drive.

- Q: 1325 woodworking engraving machine how to do the map?

- Cutting direction: when solid wood is cut, the wood is cut into longitudinal, horizontal, end and vertical ends, longitudinal and vertical and transverse ends according to the cutting edge relative to the direction of the wood fiber.

- Q: How can the engraving machine slide the table?

- A thorough understanding of the tool setting principle of the engraving machine is of great significance for the operator to keep a clear idea of the tool, master the operation of the tool setting and put forward new tool setting methods. The aim of the tool setting is to establish the workpiece coordinate system, and the intuitive way is that the tool setting is to establish the position of the workpiece in the engraving machine workbench, in fact, it is to seek the coordinates of the tool point in the coordinate system of the worktable. For engraving machines, in order to select the tool point before machining, the tool point is the starting point of the tool relative to the workpiece when the workpiece is machined by the engraving machine. The knife point can be located on the workpiece (such as workpiece design datum or datum), can also be located in the fixture or bench, or in a fixture or a point on the table, the size must be relationship with the workpiece positioning benchmark maintaining accuracy.

- Q: What kind of wood do woodworking machines usually use?

- Camphor wood, texture staggered, delicate structure, smooth noodles, shiny, dry deformation after a small, durable, adhesive performance is good, easy to dye, rings are obvious, there are aromatic ignorant.

- Q: Woodworking engraving machine prices?

- Three procedures wooden door engraving machine, the market is normal in 4 - 55 thousand

- Q: Woodworking engraving machine why back to origin Z axis limit alarm?

- Generally, when the mechanical origin is returned, the Z shaft will not limit the alarm.

- Q: The difference between woodworking engraving machine and die engraving machine

- Simply put, if you are now woodworking machine is 180 long spindle, is certainly not carved mold, if it is about 270 of the spindle can be used! As for the service life, it depends on the material used for the spindle itself! What I'm talking about is the length of the motor! You should use 1.5KW 80 or 85 of the outer diameter of this motor length, manufacturers have the same, some are not the same, generally used in the mold 1.5KW length should be 270!

- Q: How much money a cabinet door carving machine

- The price is not cheap ah, woodworking engraving machine engraving machine: the most species, according to the function can be divided into a wood processing center automatic tool change function and process of engraving machine, engraving machine with four axis stereo stereo engraving, woodworking engraving machine and ordinary derivative of the first single, independent head multi head, pull engraving machine generally adopts XY axis adopts rack drive, Z axis adopts screw drive, a woodworking engraving machine adopts screw drive, the main processing objects of the class name is wood engraving machine, mainly for: plate cutting, hollow, walking lace, relief engraving processing etc..

- Q: Woodworking engraving machines should have several functions

- The system adopts the genuine computer operating system, which is easy to operate, fast and stable.4, three axis drive all use Taiwan silver original screw rod, higher accuracy.

- Q: Woodworking engraving machine when carving, Y axis serious jitter, stuck

- It may also be Weihong card problem, you can put the machine stop off, but it must not operate the machine back to the origin, directly set the processing position to start processing line.

Send your message to us

2014 NEWES HEFEI SUDA newest engraving machine on promotion

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords