Professional latest cnc engraving machine for woods

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1

- Supply Capability:

- 30 /month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.Syntec control system

2.9.0kw ai cooling spindle

3.Janpan Servo motor

4.Taiwan Hinwin rail

5.Vacuum table

Professional muti-function cnc engraving machine 1325

Main technical parameter

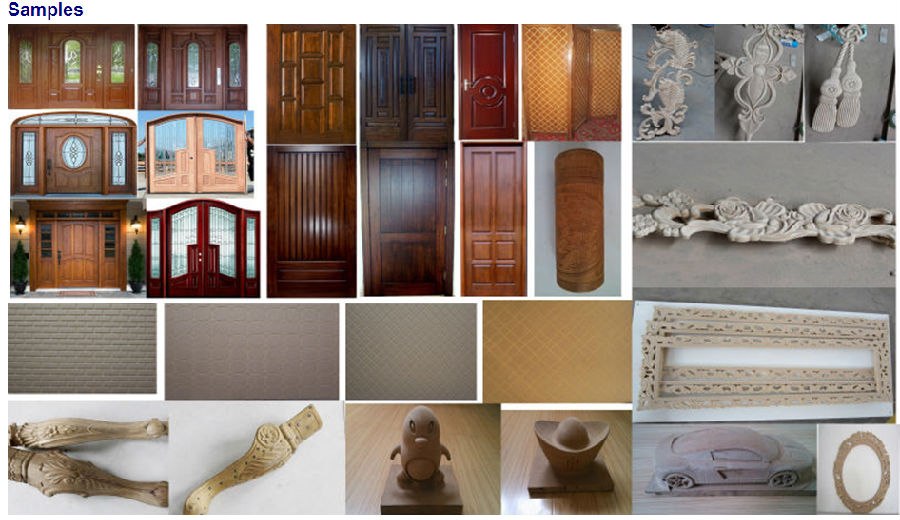

It can be used in carving on waved board, furniture door, arts door, paint free door, screen door and kinds of furniture.

Machine Size Work Envelope Repositioning Resolution Resolution Power Of Spindle Spindle Speed Max.Speed Max.Cutting Speed Bridge Clearance Control System Working Voltage Command Code | 2100×3500mm 1300×2500mm +0.02mm +0.001mm 9kw 0-18000(24000)rpm/Min 60000mm/Min 25000mm/Min 400mm SYNTEC control system AC380V/50Hz HPGL\G |

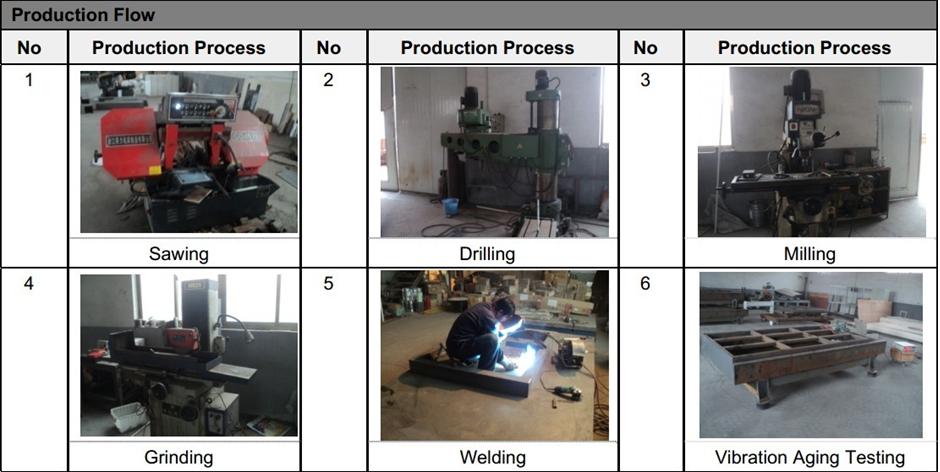

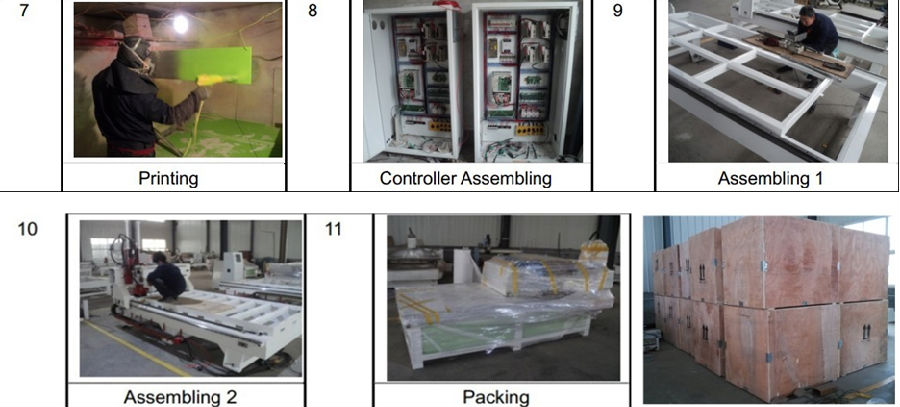

Machinery Characteristics:

Stable Structure: Square steel formed frame, stable and can not be deformed.

Perfect Parts: Imported Taiwan control system;AMT Line guide rail maid in Taiwan, due-row, four line ball slider, heavy loading and steady proceeding, German made ball lead screw with accurate cutting, Japan Servo Control system

Italy spindle motors.

l Good parts: The drive is more powerful: the use of well-known brands stepper motor,

become more powerful

l Armless automatic tool change system;magazine capacity 8(optional)

l High adhesion vacuum suction device;Displacement up to 230 cubic meters / hour

l Open software interface,.Excellent compatibility compatible of TYP3/ARTCAM/CASTMATE/WEITAI and other CAD/CAM design software Ensure that the design no problem.

- Q: Woodworking engraving machine vacuum pump commissioning notes?

- Start the motor, when the water ring vacuum pump after normal operation, open the outlet pressure gauge and import vacuum pump, as it shows the appropriate pressure, gradually open the gate valve, and check the motor load.

- Q: 1325 what does "1325" mean in woodworking machines?

- Ordinary customers generally 1325 woodworking engraving machine can meet, such as wooden doors, cabinets, doors, panels, furniture and other industries. Some special industries, such as coffins, need other models, such as 1625 woodworking engraving machines, 1825 woodworking engraving machines, customized woodworking engraving machines, etc.. Customers should buy the corresponding types of plate according to the size of their processing machines, there is no need to large machines, is a space, but the bed is too large may cause the instability of the machine and some other conditions, different size of the machine, the stability to be equipped with different bed and accessories to keep machine. Choosing the right one is the best.

- Q: How to use the woodworking engraving machine?

- Bought carving opportunities, after sales training, fool type operation, training 3 hours, can immediately mount guard

- Q: Woodworking engraving machine how much money?

- Woodworking engraving machine prices are based on the level of engraving machine to determine the level.

- Q: Can woodworking engraving machine carve bamboo?

- You need to see what carving effect, if necessary relief must be woodworking engraving machine, if only the plane carving, sure to choose the laser engraving machine, high speed, high precision, woodworking engraving machine carved out of print

- Q: How can the engraving machine slide the table?

- In the numerical control woodworking engraving machine, the machining origin of the engraving material should be determined firstly, so as to establish an accurate machining coordinate system and consider the influence of the different sizes of the cutters on the machining. The precision of tool setting determines the machining accuracy of parts. At the same time, the efficiency of tool setting also directly affects the efficiency of engraving, which needs to be solved by tool setting.

- Q: How much is the wood carving machine?

- Woodworking engraving machine is to pay attention to the wood processing, make it more beautiful. Woodworking engraving machine types currently on the market variety, the quality and the price is also uneven, therefore, when choosing woodworking engraving machine to select carefully, or put your needs to inform the staff Dewin engraving machine according to what you say they will request to choose the most suitable models for you.

- Q: Woodworking engraving machine how to engrave three-dimensional characters (the word is curved inside the deepest)

- It's a cone shaped knife, carved with a three dimensional path

- Q: The cupboard door engraving machine price how much money

- Shandong morning security engraving machine, woodworking engraving machine, stone engraving machine, three-dimensional engraving machine, multi engraving machine and other engraving equipment

- Q: CNC woodworking engraving machine which brand is good?

- The coffin engraving machine, engraving machine single head, double majority, odd star through the past two years of data analysis, the coffin carving machine double is common market is the main processing factory, high efficiency.

Send your message to us

Professional latest cnc engraving machine for woods

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1

- Supply Capability:

- 30 /month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords