CMAX PS Foamed Picture Frame Extrusion Line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Wooden case |

| Delivery Detail: | 30working days after receiving the prepayment |

PVC PS Plastic Foamed Profile Production line

This line can produce high quality low foam profiles for users.

This production line is mainly composed of extruder and SJBZ low foam profile auxiliary machine combined with advancement, reliability and practicability. This line can produce high quality low foam profiles for users.

CMAX Series PS Foam Profile Extrusion Line, consists of single screw extruder and the special co-extruder, with the cooling water tank, hot stamping machine system, haul-off unit, and stacker.

This line with imported ABB AC inverter control, imported RKC temperature meter etc. and features of good plasticization, high output capacity, and stable performance etc.

The hot stamping machine system combined foreign technology, by the hot stamping embossing method, transfer the

coating layer from the film to the PS foamed profile. The machine with good appearance, stable performance, accurate & easy operation.

By adjust the embossing wheel the machine can work on various of different profiles.

Working together with the main extruder and other extrusion down steam equipments, this line is popular as the latest developed producing line.

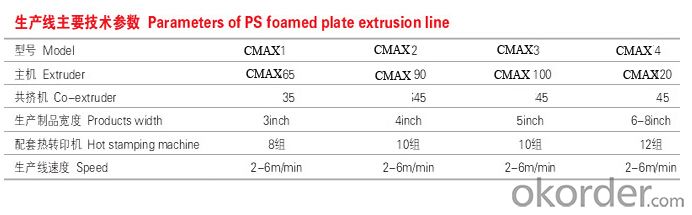

Main technical parameters:

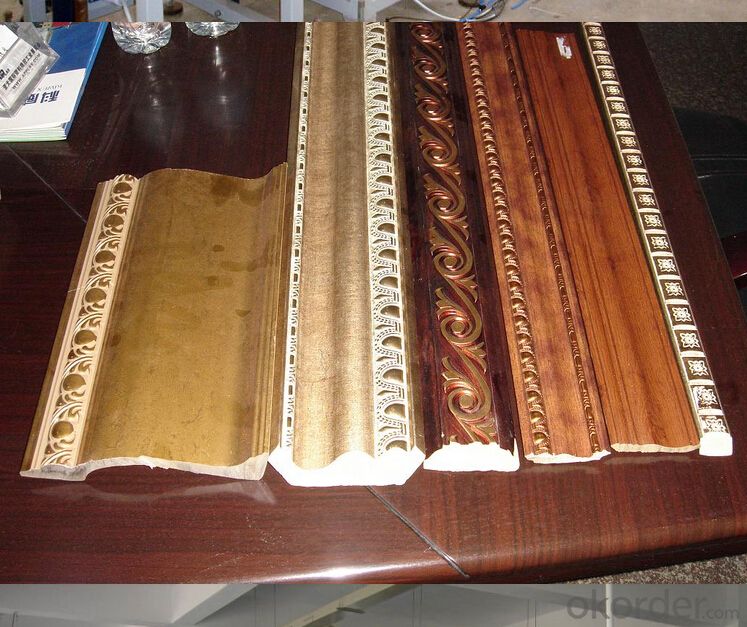

Product show:

- Q: when I use armature voltage feedback (host start speed 50, normal can produce 10It is normal to start at 80 or 150 of the speed, but after a few minutes the motor does not turn. 590 alarm (missing pulse alarm). When I change the feedback mode to speed feedback, my host sometimes starts and sometimes fails to start. I hope you help me, how should I adjust?. Thank you。

- You can adjust the proportional gain, and if you don't move, the parameter has this problem, you should check to see if you really lost the pulse

- Q: Basic parameters of extruder screw

- 1, screw diameter Ds screw diameter is the diameter of the thread, the extruder production capacity (extrusion amount) is approximately proportional to the square of the diameter of the screw and, under the same other conditions, the screw diameter increases a little, significant increase will cause extrusion amount, the effect was even greater than the effect of the increase of screw speed on the extrusion rate is high. Therefore, the screw diameter is used to characterize the specifications of the extruder.

- Q: extrusion machine prone to coke material, what is the cause? How to improve or solve?

- Is the place where the material is easy to burn rough? Add stabilizers and lubricants appropriately.

- Q: Comparison of injection molding machines and Extruders

- Considerations for extruder use:1, extrusion machine is running forward, avoid reverse2, avoid fasting operation, must heat engine feeding operation, so that can avoid sticking bar (holding shaft) phenomenon3, the extruder inlet, vent hole is strictly prohibited access to iron and other miscellaneous, so as not to cause accidents, affect production4, safe use of electricity, grounding wire5. When the machine is running, it is forbidden to touch the rotating parts such as the material inlet, the material outlet, the belt, the gear and so on6, before using the machine should be injected with lubricating oil, so as not to cause damage to the machineSince the extruder as one of the three synthetic plastic material since the advent of rapid development.

- Q: Which type of inverter is suitable for extruding machine? Please give expert advice, and G series is discontinued

- Proposed Delta VFD-cp Series ~!AskCP2000 is constant pressure water supply... Are you sure you can use it? And C2000 is better than qualifiedChasing the answerWrong number ~ ~ should be C2000, and VE Series ~ ~ these two are suitable, ~~B, CP is not good ~!

- Q: Taper twin screw extrusion machining of plastic masterbatch? What ancillary equipment do you need?

- because itself is not suitable for the design of double cone, adjustment of the formula is the key.

- Q: The working principle of an extruder

- The material is moved forward by the extrusion of the screw and the barrel, and the material is fully homogeneous and plasticized in the process of material advance. Then the material is extruded by a certain shape of the die by the die of the die.

- Q: What are the components of an extruder?

- The driving system of an extruder is to drive the screw, providing the torque and speed required by the screw in the extrusion process, usually consisting of an electric motor, a reducer, and a bearing.3. heating and cooling device for extruderHeating and cooling are necessary conditions for the process of making a plastic extruder. It includes two aspects:(1) now host extruder is usually divided into electric heating, resistance heating and induction heating, heating installed in the fuselage, neck, head of each part. The heating device heats the plastic in the outer barrel to increase the temperature required for the process operation.(2) the cooling device is designed to ensure that the plastic is in the temperature range required by the process. Specifically, to eliminate the excess heat generated by the shear friction of the screw rotation, in order to avoid the temperature is too high, so that plastic decomposition, coke burning or stereotypes difficult. Cylinder cooling water cooling and air cooling is divided into two kinds, small and medium sized extrusion machine adopts air cooling is more appropriate, large use more water or two kinds of combined cooling; cooling water cooling screw mainly adopts the center, the purpose is to increase the solids conveying rate, stable glue volume, and improve product quality; but in the cooling hopper one is, in order to strengthen transport of solid material, prevent warming plastic sticky jam outlet, two is to ensure the normal work of the transmission part.

- Q: Who knows the temperature regulation method of the extruder?Any information will do

- Extrusion molding in plastic processing is called extrusion, using hydraulic pressure in rubber extruder processing in extrusion die extrusion. That itself means that the material through the extruder barrel and screw the function between the side heating plasticization, screw edge is pushed forward, a processing method of continuous head made by various sections of finished or semi-finished products.In the fiber chemical industry is also useful in the extruder to the spinneret for melt spinning. The material, process of extrusion used in thermoplastic plastics and rubber, for batching, granulation, rubber filtration, continuous production, manufacturing various continuous products such as pipe, profile, sheet (or sheets), thin film wire and cable coating, rubber tire, tube noodles barrel, a sealing strip, the production efficiency is high. In the production of synthetic resin, can be used as reactor extruder, continuous polymerization and processing, in rubber industry, the compression ratio of different extruding machine can be used to unmasticated natural rubber of different materials. Compression extrusion machine than some different. [edit this paragraph] the principle of extrusion molding material since the bucket into the barrel, the screw rotates under the action of the cylinder wall and the surface of the screw friction shearing forward delivery to the feeding section in the loose. Forward transport also is compacted; the compression section, screw groove depth, further compaction, while the barrel heating and screw and cylinder wall friction shear, the material temperature rise began to melt, the compression section ends; homogeneous section material uniform, constant temperature, fixed quantity, squeeze out to melt. After a head forming, by setting the product.

- Q: Ask everyone about the extrusion machine at the wire factory...... How do you adjust the speed of the motor?

- One is the use of frequency converter connection, in accordance with the frequency converter user manual guidance method to adjust the speed, in addition to the use of electromagnetic speed control motor, through the speed box above potentiometer adjust speed.

Send your message to us

CMAX PS Foamed Picture Frame Extrusion Line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords