CMAX Series PE,PP And Wood, PVC And Wood (Foamed) Panel Extrusion Line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | standard wooden case |

| Delivery Detail: | 20 working days |

The extruder is equipped with the temperature controlling gauges which have the advantages of high precision temperature controlling, easy and reliable operation.

The vacuum calibration table equipped with the strong cooling device which ensures the cooling effect. Caterpillar type haul off unit, equipped with the precise speed reduction motor and inverter, has the advantages of reasonable structure,powerful and stable haul off force. The cutter has the reliable and accurate cutting effect.

The stacker has the movable stacking trolley and special made rubber protection layer to prevent the product from being scratched. The downstream equipment of this extrusion line uses the programmable computer or domestic made controlling system for stable and reliable operation.

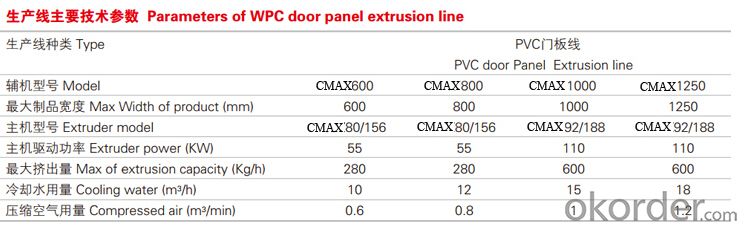

Technical parameters

Product show:

- Q:Cable extrusion machine 6.57090 machine model how to see, know the master to say, thank you

- Screw diameterAskDo you mean the plastic screw? 90 machines are so long. What's the 90 machine? Thank youChasing the answerDiameter, not length

- Q:extrusion machine prone to coke material, what is the cause? How to improve or solve?

- Or the outer lubrication part of low molecular weight is replaced by macromolecule lubrication

- Q:Now I want to do it How to change the equipment, please help tell your heroes ah!Used to do PVC pinch plate, now changed to PVC threading tube

- Do the plate equipment and pipe threading with PVC equipment, from the process, are PVC extrusion machinery, however, do different products, screw inside or something different, if you want to do product grade requirements is not high, can change, but stability is not so good ensure product.

- Q:Which type of inverter is suitable for extruding machine? Please give expert advice, and G series is discontinued

- Proposed Delta VFD-cp Series ~!AskCP2000 is constant pressure water supply... Are you sure you can use it? And C2000 is better than qualifiedChasing the answerWrong number ~ ~ should be C2000, and VE Series ~ ~ these two are suitable, ~~B, CP is not good ~!

- Q:Extruder price

- According to the size of the screw, single and double screw configuration is different, there are many different prices between fifty thousand to two hundred thousand, we specialize in the production of extruders, crushers and mixing machines, high quality and low price, contact information on the user name

- Q:The working principle of an extruder

- What is the working principle of an extruder?:Screw with specific shape,Turn in a heated barrel,It will be delivered from the hopperThe plastic is pressed forward, allowing the plastics to be uniformly plasticized (i.e., melted)Through the head and different shapes of the mold, the plastic extrusionA continuous plastic layer of various shapes, extruded on the core and cable.

- Q:Produce 10 square wires with the smallest extruder

- If it is a production sheath line, do at least 70 machines, preferably 70 or 90 insulation, and 90/120 as sheath

- Q:1: what is the difference between an extruder and an injection molding machine?Answer the questions in terms of structure, process, product difference, material distinction, mould distinction and development areaThis is a kind of mechanical professional mold mold equipment on an essay question, please the professional teacher to help answer, thank you very much, the students have urgent need, thank you!!

- 2: injection molding machine, mainly to melt the plastic injection molding process, after the mold injection molding machine outjection. The main products are mechanical parts, containers, household appliances shell.

- Q:Comparison of injection molding machines and Extruders

- Considerations for extruder use:1, extrusion machine is running forward, avoid reverse2, avoid fasting operation, must heat engine feeding operation, so that can avoid sticking bar (holding shaft) phenomenon3, the extruder inlet, vent hole is strictly prohibited access to iron and other miscellaneous, so as not to cause accidents, affect production4, safe use of electricity, grounding wire5. When the machine is running, it is forbidden to touch the rotating parts such as the material inlet, the material outlet, the belt, the gear and so on6, before using the machine should be injected with lubricating oil, so as not to cause damage to the machineSince the extruder as one of the three synthetic plastic material since the advent of rapid development.

- Q:Ask everyone about the extrusion machine at the wire factory...... How do you adjust the speed of the motor?

- One is the use of frequency converter connection, in accordance with the frequency converter user manual guidance method to adjust the speed, in addition to the use of electromagnetic speed control motor, through the speed box above potentiometer adjust speed.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

CMAX Series PE,PP And Wood, PVC And Wood (Foamed) Panel Extrusion Line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products